3348319

O Ring Seal

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3348319 O Ring Seal is a vital component designed to maintain the integrity of seals within commercial truck engines. Its primary function is to prevent leaks and ensure system efficiency. This part contributes to the reliable operation of truck engines by ensuring that fluids and gases remain contained within their designated pathways.

Basic Concepts of O Ring Seals

An O Ring Seal is a type of gasket made from a circular section of elastomer with a round cross-section. It functions by being seated in a groove and compressed during assembly between two or more mating surfaces, creating a seal at the interface. O Ring Seals are widely used in mechanical systems to prevent the leakage of fluids and gases and to protect against the ingress of contaminants 1.

Role of the 3348319 O Ring Seal in Truck Operation

The 3348319 O Ring Seal plays a specific role in the operation of a truck by ensuring the sealing of certain components within the engine system. It is associated with systems where fluid or gas containment is necessary to maintain engine performance and efficiency. The seal helps in maintaining the pressure and purity of the systems it is a part of, which is vital for the overall functionality of the truck 2.

Key Features of the 3348319 O Ring Seal

The 3348319 O Ring Seal is characterized by its material composition, which is typically a durable elastomer chosen for its resistance to the operating conditions it will face. The design specifications of the seal include its size and the precision of its fit within the designated groove. Unique characteristics may include enhanced resistance to wear, temperature extremes, and chemical exposure, which contribute to its performance 3.

Benefits of Using the 3348319 O Ring Seal

The advantages provided by the 3348319 O Ring Seal include improved sealing efficiency, which leads to better system performance and reduced maintenance needs. Its durability ensures a longer service life, and its resistance to various operating conditions makes it suitable for use in demanding environments typical of commercial truck operations 4.

Installation and Maintenance Guidelines

Proper installation of the 3348319 O Ring Seal involves ensuring that the groove is clean and free of debris before placing the seal. The seal should be lubricated to facilitate installation and to prevent damage. Regular maintenance includes checking for signs of wear or degradation and replacing the seal as necessary to prevent leaks and maintain system integrity.

Troubleshooting Common Issues

Common problems associated with O Ring Seals, such as leaks or failures, can often be traced to improper installation, degradation due to exposure to harsh conditions, or physical damage. Troubleshooting methods include inspecting the seal and its groove for damage, ensuring proper installation techniques are used, and selecting the appropriate seal material for the operating conditions.

Manufacturer Information - Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, as well as related technologies. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s product range includes a variety of components and systems designed to enhance the performance and reliability of commercial vehicles.

Cummins O Ring Seal 3348319 Compatibility

The Cummins O Ring Seal part number 3348319 is designed to fit seamlessly with a range of Cummins engines, providing reliable performance and durability. Below is a detailed description of the engines that are compatible with this O Ring Seal.

ISX Series Engines

- ISX CM570

- ISX CM871

- ISX12 CM2350 X102

- ISX12 G CM2180 EJ

- ISX12/ISX11.9 CM2250

- ISX15 CM2250

- ISX15 CM2350 X101

- QSX11.9 CM2250 ECF

- QSX15 CM2250

- QSX15 CM2250 ECF

- QSX15 CM2350 X105

QSB Series Engines

- QSB5.9 CM850

- QSB6.7 M CM2250

QSK and QST Series Engines

- QSK78 CM500

- QST30 CM2350 T101

QSX Series Engines

- QSX15 CM2250

- QSX15 CM2250 ECF

- QSX15 CM2350 X105

QSZ Series Engines

- QSZ13 CM2150 Z101

- QSZ13 CM2150 Z102

X Series Engines

- X12 CM2350 X119B

- X15 CM2350 X116B

- X15 CM2450 X134B

Z Series Engines

- Z14 CM2670 Z103B

ISZ Series Engines

- ISZ13 CM2150 Z105

QSV Series Engines

- QSV91-G4 CM558/CM700 V102

This O Ring Seal is designed to fit snugly within the specified engine models, ensuring that there are no leaks and that the engine operates efficiently. The compatibility of this part with such a wide range of engines underscores its versatility and importance in maintaining engine integrity.

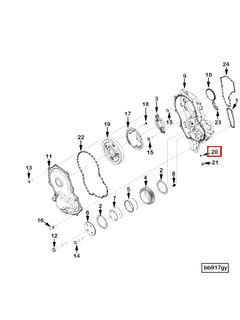

Role of Part 3348319 O Ring Seal in Engine Systems

The 3348319 O Ring Seal is instrumental in ensuring the integrity and efficiency of various engine systems by providing essential sealing functions. In the aftercooler, it prevents coolant leaks, maintaining optimal cooling of compressed air. Within the air compressor, the O ring ensures that pressurized air does not escape, thus preserving system efficiency.

In the air control valve and air flow metering orifice, the seal prevents air leaks, ensuring accurate air measurement and control, which is vital for combustion efficiency. For the engine oil cooler, the O ring maintains the seal between coolant and oil passages, preventing cross-contamination and ensuring effective heat exchange.

The exhaust cooler leak test kit relies on the O ring to create a sealed environment during testing, allowing for accurate detection of leaks. In the exhaust gas recirculation venturi and associated exhaust recirculation air arrangement and plumbing, the seal ensures that recirculated exhaust gases are properly metered and do not leak, contributing to reduced emissions.

In the expansion tank, the O ring seal prevents coolant loss, maintaining the correct coolant level and pressure. The fuel control housing and module, as well as the fuel pump head and fuel supply plumbing, depend on the O ring to prevent fuel leaks, ensuring safe and efficient fuel delivery.

For the fuel systems HD XPI and gear fuel pump, the seal is essential in maintaining high-pressure fuel integrity, which is critical for precise fuel injection. The hand hole cover utilizes the O ring to create a sealed access point, protecting internal components from contaminants.

In the hardware certification kit, the O ring ensures that test conditions are maintained without leaks. The heat exchanger set and upper gasket rely on the seal to prevent fluid leaks, ensuring efficient heat transfer.

The turbocharger leak test kit and plumbing use the O ring to create a sealed system during testing and operation, respectively. Finally, in the XPI JV components and system for Scania HD engines, the O ring ensures that high-pressure fuel lines and connections remain leak-free, contributing to the overall performance and reliability of the fuel system.

Conclusion

The Cummins 3348319 O Ring Seal is a critical component in maintaining the integrity and efficiency of various engine systems. Its role in preventing leaks and ensuring system efficiency is paramount for the reliable operation of commercial truck engines. Proper installation, regular maintenance, and understanding the compatibility of this part with various Cummins engines are essential for maximizing its performance and longevity.

-

Martyr, A.J. (2007). Engine Testing: Theory and Practice: Third Edition. SAE International.

↩ -

Kluczyk, B. (2008). How to Rebuild Any Automotive Engine. CarTech.

↩ -

Wharton, A. J. (1991). Diesel Engines. Butterworth-Heinemann Ltd.

↩ -

Dixon, J. C. (1996). Tyres Suspension and Handling Second Edition. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.