This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3330941 O-Ring Seal is a component manufactured by Cummins, a well-established name in the commercial truck industry. This O-Ring Seal is designed for use in various systems within commercial trucks, ensuring the integrity and efficiency of these systems through effective sealing.

Basic Concepts of O-Ring Seals

An O-Ring Seal is a type of gasket with a circular cross-section, designed to create a seal between two or more parts. It operates by being compressed within a groove, forming a barrier that prevents the leakage of fluids or gases. O-Ring Seals are widely used in mechanical systems due to their simplicity, effectiveness, and versatility in various applications 1.

Purpose of the 3330941 O-Ring Seal in Truck Operations

This Cummins part plays a specific role in the operation of commercial trucks by ensuring the sealing integrity of various systems and components. It is commonly associated with fuel systems, hydraulic systems, and other critical areas where fluid or gas containment is necessary. By providing a reliable seal, it helps maintain system efficiency and prevent leaks that could lead to performance issues or safety concerns 2.

Key Features of the 3330941 O-Ring Seal

The 3330941 is characterized by its design and material properties, which include durability, resistance to specific fluids encountered in truck operations, and an operational temperature range that suits the demanding conditions of commercial truck environments. These features make it well-suited for its intended applications, ensuring long-lasting performance and reliability 3.

Benefits of Using the 3330941 O-Ring Seal

Utilizing this part offers several advantages, such as improved system reliability through effective sealing, reduced maintenance needs due to its durability, and enhanced performance in sealing applications. These benefits contribute to the overall efficiency and safety of commercial truck operations 4.

Installation Considerations

Proper installation of the 3330941 is vital for ensuring optimal performance and longevity. Guidelines and best practices for installation include ensuring the groove is clean and free of debris, using the correct installation tools to avoid damage, and verifying that the O-Ring is seated properly within the groove. Attention to these details helps maintain the seal’s integrity and effectiveness.

Troubleshooting Common Issues

Common problems associated with O-Ring Seals, such as leaks or failures, can often be traced back to installation errors, environmental factors, or material degradation. Troubleshooting steps may include inspecting the seal and groove for damage, checking for proper installation, and assessing the compatibility of the O-Ring material with the fluids and temperatures it encounters. Addressing these issues promptly can help restore system integrity and prevent further complications.

Maintenance Tips

Regular maintenance of the 3330941 is recommended to ensure continued performance and reliability. This includes periodic inspection for signs of wear or damage, cleaning the seal and groove as necessary, and replacing the O-Ring when it shows signs of degradation or failure. Adhering to these maintenance practices helps extend the life of the seal and maintain system efficiency.

Cummins: A Brief Overview

Cummins is a renowned manufacturer in the commercial truck industry, known for its wide range of products and strong reputation for quality and reliability. With a history of innovation and commitment to customer satisfaction, Cummins continues to be a leading provider of diesel engines, natural gas engines, and related technologies for commercial vehicles. Their product range includes engines, filtration systems, emissions solutions, and aftermarket parts, all designed to meet the demanding requirements of the commercial trucking sector.

Cummins O-Ring Seal 3330941 Compatibility with Engine Models

The Cummins O-Ring Seal part number 3330941 is designed to fit seamlessly within several engine models, ensuring optimal sealing performance and reliability. This O-Ring Seal is engineered to meet the stringent requirements of various Cummins engines, providing a critical barrier against leaks and ensuring the integrity of the engine’s systems.

B5.9 G and B5.9 GAS PLUS CM556

The O-Ring Seal 3330941 is compatible with the B5.9 G and B5.9 GAS PLUS CM556 engines. These engines are known for their robust performance and efficiency, and the O-Ring Seal plays a vital role in maintaining the seal integrity of critical components, ensuring smooth operation and longevity.

G5.9 and ISM CM570/870

Similarly, the O-Ring Seal 3330941 is also suitable for the G5.9 and ISM CM570/870 engines. These engines are designed for heavy-duty applications, and the O-Ring Seal’s precision fit and durability are essential in maintaining the high standards of performance and reliability expected from these models.

L10 GAS

The L10 GAS engine also benefits from the use of the O-Ring Seal 3330941. This engine is engineered for demanding applications, and the O-Ring Seal ensures that all critical seals are maintained, preventing leaks and ensuring the engine operates at peak efficiency.

By providing a precise fit and reliable sealing performance, the O-Ring Seal 3330941 is an essential component for the engines listed, ensuring that they operate efficiently and reliably under various conditions.

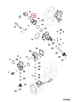

Role of Part 3330941 O-Ring Seal in Engine Systems

The part 3330941 O-Ring Seal is instrumental in ensuring the integrity and efficiency of various engine systems. In the Air Intake Connection, it provides a tight seal that prevents air leaks, ensuring optimal air-fuel mixture for combustion.

Within the Assembly Kit, the O-Ring Seal is used to maintain the seal between components, reducing the risk of fluid or gas escape which could lead to inefficiencies or failures.

In the Exhaust Gas Recirculation (EGR) Mixer Ejector and EGR Mixer Venturi, the O-Ring Seal plays a significant role in maintaining the seal at connection points. This ensures that recirculated exhaust gases are properly mixed with the incoming air, enhancing emission control and engine performance.

For the Fuel Control and Fuel Control Module, the O-Ring Seal is essential in preventing fuel leaks. It ensures that fuel is delivered accurately and consistently to the combustion chamber, which is vital for engine operation and fuel efficiency.

In the Fuel Flow Sensor, the O-Ring Seal helps in maintaining a sealed environment, ensuring accurate measurement of fuel flow rates. This is important for precise fuel management and engine performance.

The Fuel Transfer Right Hand Engine Kit utilizes the O-Ring Seal to ensure that fuel transfer between components is leak-free. This is critical for maintaining the integrity of the fuel system and ensuring reliable engine operation.

Lastly, in the Mass Flow Sensor, the O-Ring Seal ensures that air entering the sensor is measured accurately without any leaks, which is essential for the sensor to provide reliable data for engine management systems.

Conclusion

The 3330941 O-Ring Seal is a critical component in the maintenance and operation of commercial truck engines, ensuring the integrity and efficiency of various systems through effective sealing. Its compatibility with multiple Cummins engine models underscores its importance in maintaining high standards of performance and reliability. Proper installation, regular maintenance, and prompt troubleshooting of common issues are essential practices to maximize the benefits of this Cummins part, contributing to the overall efficiency and safety of commercial truck operations.

-

Rajamani, R. (2005). Vehicle Dynamics and Control. Springer.

↩ -

Hu, H., Smaling, R., & Baseley, S. (2014). Heavy-Duty Wheeled Vehicles. SAE International.

↩ -

Department of Energy. (2015). Department of Energy Fundamentals Handbook.

↩ -

Awari, G.K., Kumbhar, V.S., & Tirpude, R.B. (2011). Automotive Systems Principles and Practice. CRC Press.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.