3062601

O Ring Seal

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

Minimum Quantity 6

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3062601 O Ring Seal is a component designed for use in heavy-duty truck maintenance. It serves a specific purpose within the truck’s mechanical systems, contributing to the overall efficiency and reliability of the vehicle. Understanding its function and significance is important for maintaining the performance of heavy-duty trucks.

Basic Concepts of O Ring Seals

An O Ring Seal is a type of gasket consisting of a ring of elastomer with a round cross-section. It functions by creating a seal between two or more parts, preventing the leakage of fluids or gases. O Ring Seals are widely used in mechanical systems due to their simplicity, effectiveness, and versatility in various applications 1.

Role of the 3062601 O Ring Seal in Truck Operation

The 3062601 O Ring Seal plays a role in the operation of a truck by ensuring the integrity of seals within specific systems. It is part of the engine’s cooling and lubrication systems, where it helps maintain the proper flow of fluids without leakage. This contributes to the overall performance and longevity of the truck’s engine 2.

Key Features of the 3062601 O Ring Seal

The 3062601 O Ring Seal is characterized by its material composition, which is designed to withstand the harsh conditions encountered in heavy-duty applications. It is made from durable elastomers that offer resistance to oils, fuels, and temperature variations. Its design ensures a snug fit in the designated grooves, providing a reliable seal.

Benefits of Using the 3062601 O Ring Seal

Using the 3062601 O Ring Seal offers several advantages. It provides improved sealing efficiency, which is vital for maintaining the performance of the truck’s systems. Its durability ensures longevity, reducing the frequency of replacements. Additionally, it exhibits resistance to various operating conditions, enhancing the reliability of the seal.

Troubleshooting Common Issues with O Ring Seals

Common issues with O Ring Seals include leaks or wear, which can compromise the seal’s effectiveness. Identifying these problems involves inspecting the seal for signs of damage or deformation. Addressing these issues may require cleaning the sealing surfaces, ensuring proper alignment, or replacing the seal if necessary.

Maintenance Tips for O Ring Seals

Regular maintenance of O Ring Seals is important to ensure optimal performance. This includes periodic inspection for wear or damage, cleaning the sealing surfaces to remove contaminants, and replacing the seal according to the manufacturer’s guidelines or when signs of degradation are observed.

Installation Guidelines

Proper installation of the 3062601 O Ring Seal is important for its effectiveness. This involves ensuring the seal is correctly fitted into the designated groove without twisting or damage. Alignment with the mating surfaces should be precise to achieve a reliable seal.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins is committed to providing reliable and efficient solutions for the automotive industry, including a wide range of parts and components for heavy-duty trucks.

Role of Part 3062601 O Ring Seal in Engine Systems

The 3062601 O Ring Seal is an essential component in ensuring the integrity and efficiency of various engine systems. Its application spans across multiple components, each playing a distinct role in the overall functionality of the engine.

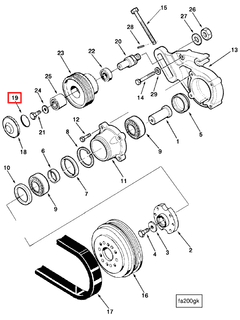

Drive Fan and Fan Clutch Mounting Kit

In the drive fan and fan clutch mounting kit, the O Ring Seal is utilized to create a secure and leak-proof connection between the fan and the engine block. This seal prevents coolant or other fluids from escaping, maintaining the efficiency of the cooling system and ensuring that the fan operates within optimal parameters.

Fan Drive and Fan Support

For the fan drive and fan support, the O Ring Seal is instrumental in sealing the connections where the fan drive attaches to the engine. This prevents any fluid leakage that could lead to decreased performance or damage to surrounding components. The seal also helps in reducing friction and wear by maintaining a consistent lubricant film.

Idler Pulleys

Across various idler pulleys, including the painted idler pulley, top-level assembly idler pulley, and backside idler pulley, the O Ring Seal plays a significant role. It ensures that the bearings within these pulleys remain lubricated and protected from contaminants. This extends the lifespan of the pulleys and ensures smooth operation of the accessory drive belts.

Idler Top Level Assembly Pulley

In the idler top level assembly pulley, the O Ring Seal is used to maintain the integrity of the lubricant within the pulley’s housing. This is vital for the pulley’s ability to adjust tension in the belt system, which is crucial for the efficient operation of engine accessories like the alternator, water pump, and air conditioning compressor.

Product Installation Package

When included in a product installation package, the O Ring Seal ensures that all components are properly sealed during the installation process. This is particularly important in maintaining the warranty and performance guarantees of the installation kit, as it prevents fluid leaks and contamination that could arise from improper sealing.

Conclusion

The 3062601 O Ring Seal is a versatile component that enhances the reliability and performance of various engine systems by ensuring secure, leak-proof connections and maintaining the integrity of lubricants within moving parts.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.