3060890

O Ring Seal

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3060890 O Ring Seal is a critical component designed to maintain the integrity of seals within heavy-duty truck systems. Its role is significant in ensuring the efficiency and reliability of truck operations. By preventing leaks and ensuring proper system function, this part contributes to the overall performance and longevity of heavy-duty trucks 2.

Basic Concepts of O Ring Seals

O Ring Seals are elastomeric rings with a circular cross-section, used to create a seal between two or more parts. They function by deforming slightly when compressed, filling the gap between mating surfaces to prevent the passage of fluids or gases. O Ring Seals are widely utilized in mechanical systems due to their simplicity, effectiveness, and versatility in various applications 1.

Purpose of the 3060890 O Ring Seal in Truck Operation

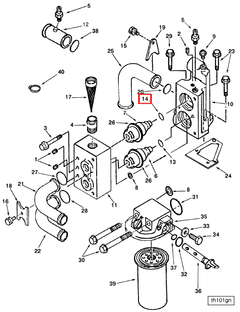

The Cummins 3060890 O Ring Seal plays a specific role in the operation of heavy-duty trucks by ensuring seals within the engine or other systems remain intact. Located in critical areas where fluid or gas passage needs to be controlled, this Cummins part helps maintain system pressure and prevent leaks. Its proper function is integral to the efficient operation of the truck, contributing to engine performance and system reliability 3.

Key Features of the 3060890 O Ring Seal

The Cummins 3060890 O Ring Seal is characterized by several primary features that enhance its performance and durability. These include its material composition, typically a durable elastomer resistant to various operating conditions, precise dimensions tailored to fit specific applications, and design features that optimize sealing efficiency. These characteristics ensure the O Ring Seal can withstand the rigors of heavy-duty truck operation 4.

Benefits of Using the 3060890 O Ring Seal

Utilizing the Cummins 3060890 O Ring Seal offers several advantages. It provides improved sealing efficiency, effectively preventing leaks and maintaining system integrity. Its resistance to wear and tear ensures longevity, even under demanding conditions. Additionally, its compatibility with various fluids and operating conditions makes it a versatile choice for heavy-duty truck applications 2.

Troubleshooting and Maintenance Suggestions

To ensure the Cummins 3060890 O Ring Seal operates effectively, it is important to be aware of common issues such as wear, damage, or improper installation. Regular inspection and replacement of the O Ring Seal as part of routine maintenance can prevent leaks and system failures. Proper installation techniques, including ensuring the mating surfaces are clean and free of debris, are crucial for optimal performance. Following manufacturer guidelines for maintenance and replacement intervals will help maintain the seal’s integrity and the system’s overall functionality 3.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the automotive and heavy-duty truck industry. Its comprehensive product range and commitment to customer satisfaction have made Cummins a preferred choice for professionals in the field 4.

Conclusion

The Cummins 3060890 O Ring Seal is an essential component for maintaining the efficiency and reliability of heavy-duty truck systems. Its role in preventing leaks and ensuring proper system function is critical for the overall performance and longevity of trucks. Regular maintenance and proper installation are key to maximizing the benefits of this part.

-

Brown Jr, Andrew. Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles. National Academy of Sciences, 2010.

↩ -

Dixon, John. Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning, 2010.

↩ ↩ -

Nunney, MJ. Light and Heavy Vehicle Technology, Fourth Edition. Butterworth-Heinemann, 2007.

↩ ↩ -

Cummins Inc. Operation and Maintenance Manual for Z14 CM2670 Z109C. Bulletin Number 6314881.

↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.