4960180

Corrosion Resistor Seal

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 4960180 Corrosion Resistor Seal, manufactured by Cummins, is a component designed to enhance the longevity and reliability of commercial trucks. Cummins, a well-established name in the automotive industry, produces a range of parts aimed at improving vehicle performance and durability. This Cummins part is particularly significant in the realm of commercial truck maintenance, offering protection against corrosion and ensuring the smooth operation of truck systems.

Basic Concepts of Corrosion Resistor Seals

Corrosion resistor seals are components used in mechanical systems to prevent corrosion. They function by creating a barrier that shields sensitive parts from moisture, chemicals, and other corrosive elements. These seals are vital in maintaining the integrity of mechanical components, ensuring they operate efficiently and have a longer service life 1. In the context of commercial trucks, these seals play a role in protecting critical components from the harsh environmental conditions often encountered on the road.

Purpose of the 4960180 Corrosion Resistor Seal

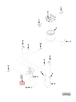

The 4960180 Corrosion Resistor Seal is designed to protect specific areas within a truck’s system from corrosion. It is typically placed in locations where moisture and contaminants can accumulate, such as around joints, fittings, and other vulnerable points. By sealing these areas, the 4960180 helps maintain the structural integrity and functionality of the truck’s components, contributing to overall system reliability.

Key Features

The 4960180 Corrosion Resistor Seal boasts several key features that enhance its performance. It is made from durable materials resistant to corrosion and wear, ensuring longevity in demanding environments. The design of the seal includes precise fitting elements that ensure a tight seal, effectively blocking out moisture and contaminants. Additionally, the seal may incorporate unique characteristics such as anti-static properties or compatibility with specific chemicals, further enhancing its protective capabilities.

Benefits

The benefits of using the 4960180 Corrosion Resistor Seal include improved durability of the truck’s components, enhanced protection against environmental factors, and contribution to overall system efficiency. By preventing corrosion, the seal helps maintain the performance and reliability of the truck, reducing the need for frequent repairs and replacements. This not only saves on maintenance costs but also ensures that the truck remains operational with minimal downtime 2.

Installation Process

Proper installation of the 4960180 Corrosion Resistor Seal is crucial for its effectiveness. The process involves cleaning the area where the seal will be placed to ensure a smooth surface. The seal is then positioned and secured using appropriate tools, ensuring it fits snugly without gaps. It may be necessary to use additional components such as gaskets or adhesives to achieve a perfect seal. Following the manufacturer’s guidelines during installation is important to ensure the seal functions as intended.

Troubleshooting Common Issues

Common problems associated with corrosion resistor seals include leaks, seal failure, and contamination. These issues can arise from improper installation, wear and tear, or exposure to harsh chemicals. Troubleshooting steps may involve inspecting the seal for damage, cleaning the area around the seal, and replacing the seal if necessary. Regular maintenance and inspection can help identify potential issues before they lead to more significant problems 3.

Maintenance Tips

To ensure the longevity and optimal performance of the 4960180 Corrosion Resistor Seal, regular maintenance is recommended. This includes periodic inspection of the seal for signs of wear or damage, cleaning the area around the seal to prevent accumulation of contaminants, and replacing the seal as needed. Adhering to a scheduled maintenance plan can help maintain the integrity of the seal and the overall efficiency of the truck’s system.

Cummins: A Brief Overview

Cummins is a renowned manufacturer in the automotive industry, known for its high-quality engines and components. With a history spanning several decades, Cummins has built a reputation for reliability and innovation. The company offers a wide range of products designed to enhance the performance and durability of commercial vehicles. Their commitment to quality and customer satisfaction has made them a trusted name among fleet operators and maintenance professionals.

Cummins Corrosion Resistor Seal 4960180 Compatibility

The Cummins Corrosion Resistor Seal, part number 4960180, is designed to fit a range of engines, providing essential protection against corrosion and ensuring the longevity of engine components. Here are the engines that are compatible with this part:

ISX12 Series

- ISX12 CM2350 X102

- ISX12 G CM2180 EJ

- ISX12/ISX11.9 CM2250

ISZ13 Series

- ISZ13 CM2150 Z105

QSX11.9 Series

- QSX11.9 CM2250 ECF

QSZ13 Series

- QSZ13 CM2150 Z101

- QSZ13 CM2150 Z102

Z13 Series

- Z13 Z108G

This corrosion resistor seal is integral to maintaining the integrity of the engine’s components, especially in environments where exposure to corrosive elements is a concern. It is essential to use this part in the specified engines to ensure optimal performance and durability.

Role of Part 4960180 Corrosion Resistor Seal in Engine Systems

The 4960180 Corrosion Resistor Seal is an essential component in maintaining the integrity and efficiency of various engine systems. It is specifically designed to prevent corrosion, which can compromise the performance and longevity of engine components.

Integration with Engine Components

-

Corrosion Resistor Head: The seal works in conjunction with the corrosion resistor head to create a barrier against corrosive elements. This ensures that the head remains unaffected by environmental factors, thus maintaining optimal engine performance.

-

Lower Engine Gasket Kit: When integrated into the lower engine gasket kit, the 4960180 seal enhances the gasket’s ability to prevent leaks and maintain compression. This is vital for the overall sealing efficiency of the lower engine components.

-

Overhaul Kit: In an overhaul kit, the corrosion resistor seal plays a significant role in protecting newly installed or refurbished parts from corrosion. This extends the lifespan of the overhaul and ensures that the engine operates smoothly post-overhaul.

-

Resistor Components: The seal is often used in conjunction with other resistor components to create a comprehensive corrosion protection system. This system is designed to safeguard sensitive parts from the detrimental effects of corrosion, ensuring consistent engine performance.

-

Corrosion Protection System: The 4960180 seal is a key element in the overall corrosion protection system of the engine. It works alongside other corrosion-resistant materials and coatings to create a robust defense against environmental corrosion.

By effectively sealing and protecting these components, the 4960180 Corrosion Resistor Seal contributes to the reliability and durability of the engine system, ensuring that all parts function as intended without the interference of corrosive damage.

Conclusion

The 4960180 Corrosion Resistor Seal by Cummins is a critical component in the maintenance and longevity of commercial truck engines. Its role in preventing corrosion ensures that engine components remain protected against environmental factors, thereby enhancing the overall efficiency and reliability of the truck. Proper installation, regular maintenance, and understanding its integration with other engine components are essential for maximizing the benefits of this part. Cummins’ commitment to quality and innovation is evident in the design and functionality of the 4960180, making it a valuable asset for fleet operators and maintenance professionals.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.