69760

O-Ring Seal

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

Minimum Quantity 2

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 69760 O-Ring Seal is a vital component designed to maintain the integrity of fluid systems within commercial trucks. It ensures reliable sealing in various applications, preventing leaks and maintaining system efficiency. This part plays a significant role in the smooth and efficient operation of engines and other systems in commercial trucks.

Basic Concepts of O-Ring Seals

An O-Ring Seal is a type of gasket made from a circular section of elastomer with a round cross-section. It functions by being seated in a groove and compressed during assembly between two or more parts, creating a seal at the interface 1. O-Ring Seals are widely used in mechanical systems to prevent the leakage of fluids and gases and to exclude contaminants from entering sensitive areas.

Purpose of the Cummins 69760 O-Ring Seal

The Cummins 69760 O-Ring Seal is specifically designed to fit within the engine or other systems of a truck, where it serves to seal connections and prevent fluid leaks. Its placement is typically in areas where fluid dynamics and pressure require a robust sealing solution. By ensuring a tight seal, it helps maintain the efficiency and reliability of the truck’s systems 2.

Key Features

The Cummins 69760 O-Ring Seal is characterized by several key features that enhance its performance. It is made from high-quality elastomer materials, which provide durability and resistance to a range of operating conditions. The design specifications of the seal ensure it can withstand pressure and temperature variations commonly encountered in commercial truck operations 3.

Benefits

Utilizing the Cummins 69760 O-Ring Seal offers several advantages. It provides improved sealing efficiency, which is crucial for maintaining system performance. The seal’s durability ensures longevity, reducing the frequency of replacements. Additionally, its resistance to various operating conditions, including temperature extremes and chemical exposure, makes it a reliable choice for commercial truck applications.

Installation Considerations

When installing the Cummins 69760 O-Ring Seal, it is important to follow guidelines and best practices to ensure optimal performance and longevity. Proper installation involves ensuring the groove is clean and free of debris, using the correct lubrication during installation, and avoiding over-compression of the seal.

Troubleshooting Common Issues

Typical problems associated with O-Ring Seals include leaks and seal failure. These issues can often be traced back to improper installation, environmental factors, or wear and tear. Troubleshooting steps may involve inspecting the seal and groove for damage, ensuring correct installation practices are followed, and replacing the seal if necessary.

Maintenance Tips

To maintain the Cummins 69760 O-Ring Seal, regular inspections are recommended to check for signs of wear or damage. Maintenance schedules should include checks during routine service intervals. If signs of degradation are observed, such as cracking or hardening of the material, replacement of the seal may be necessary to prevent system failure.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a history of innovation and a strong reputation in the commercial truck industry, Cummins is known for producing high-quality components that enhance the performance and reliability of commercial vehicles.

Compatibility with Cummins Engines

The O-Ring Seal part 69760, manufactured by Cummins, is designed to ensure the integrity of various engine systems. This seal is engineered to fit seamlessly within a range of Cummins engines, providing essential sealing capabilities that prevent leaks and maintain system efficiency.

Compatibility with Specific Engine Models

- GTA38 G CMEICS G116C: The O-Ring Seal part 69760 is compatible with the GTA38 G CMEICS G116C engine, ensuring that it fits perfectly within the specified areas to maintain optimal performance and prevent fluid leakage.

- K19, K38, K50, KTA19GC: This seal is also designed to fit within the K19, K38, K50, and KTA19GC engines. Its precise dimensions and material properties ensure that it provides a reliable seal in these engines, contributing to their overall efficiency and longevity.

- QSK19 CM850 MCRS: The O-Ring Seal part 69760 is compatible with the QSK19 CM850 MCRS engine. Its design allows it to fit snugly in the designated areas, providing the necessary sealing to prevent leaks and maintain system integrity.

Grouping of Compatible Engines

For engines such as the K19, K38, K50, and KTA19GC, the O-Ring Seal part 69760 is grouped together due to their similar design requirements and operational needs. This grouping ensures that the seal fits effectively across these models, providing consistent performance and reliability.

Similarly, the GTA38 G CMEICS G116C and QSK19 CM850 MCRS engines are grouped together for the same reasons, ensuring that the seal fits seamlessly and performs optimally within these engine systems.

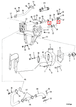

Role of Part 69760 O-Ring Seal in Engine Systems

The part 69760 O-Ring Seal is integral to ensuring the integrity and efficiency of various engine systems by providing reliable sealing solutions. Here’s how it fits within the specified components:

Cooling System Components

- Aftercooler (Rear) Kit: The O-ring seal is used to prevent coolant leaks at connection points, ensuring efficient cooling of the compressed air.

- Cooler: Seals the connections within the cooler, maintaining the coolant’s path and preventing any loss of cooling efficiency.

- Front Water Cross Connection: Ensures a tight seal at the crossover points, crucial for consistent coolant flow throughout the engine.

- Thermostat Housing: Seals the thermostat housing to prevent coolant escape, allowing for precise temperature regulation.

- Thermostat Housing Support: Provides a secure seal where the support meets the housing, ensuring structural integrity and coolant containment.

- Water By-Pass Tube: Seals the by-pass tube connections, allowing for alternative coolant flow paths when necessary.

- Water Outlet Connection: Ensures no coolant leaks at the outlet, maintaining pressure and flow within the system.

- Water Transfer Connection: Seals the transfer points, crucial for moving coolant between different engine sections.

- Water Transfer Left Bank Tube: Seals the left bank tube connections, ensuring coolant reaches all necessary areas.

- Water Transfer Mounting Tube: Provides a secure seal at the mounting points, preventing coolant loss.

- Water Transfer Plug: Seals the plug to prevent coolant leakage from the transfer system.

- Water Transfer Tube: Ensures all tube connections are leak-free, maintaining efficient coolant circulation.

Engine and Manifold Components

- Manifold, Air Intake: Seals connections within the air intake manifold, ensuring no air leaks that could affect engine performance.

- Manifold, Water: Seals water manifold connections, critical for consistent coolant distribution.

- Upper Engine Gasket Set: Complements the gasket set by providing additional sealing at various connection points.

- Single Head Gasket Set: Works in conjunction with the head gasket set to ensure no coolant or oil leaks between the engine block and cylinder head.

Additional System Components

- Base Parts and Base Parts Less Rgt: Seals various base component connections, ensuring no fluid leaks at the engine’s foundation.

- Torque Converter Oil: Seals connections within the torque converter, maintaining oil integrity and transmission efficiency.

- Gasket Set: Enhances the gasket set by providing additional sealing where needed.

- Housing: Seals housing components to prevent fluid leaks and maintain system pressure.

- Kit: Ensures all kit components are securely sealed, preventing fluid loss and ensuring system efficiency.

- WP Repair (Major): Seals major repair kit components, crucial for restoring system integrity after significant repairs.

- Starting Aid Kit: Seals connections within the starting aid system, ensuring no fluid leaks during engine start-up.

- Parts, Base, and Performance Parts: Seals various base and performance part connections, ensuring optimal engine operation and performance.

Conclusion

The Cummins 69760 O-Ring Seal is a critical component in maintaining the efficiency and reliability of commercial truck engines. Its high-quality design, durability, and compatibility with various Cummins engine models make it an essential part for ensuring optimal performance and preventing fluid leaks. Regular maintenance and proper installation are key to maximizing the benefits of this Cummins part.

-

Gillespie, T. D. (2021). Fundamentals of Vehicle Dynamics. SAE International.

↩ -

Hu, H., Baseley, S. J., & Song, X. (2021). Advanced Hybrid Powertrains for Commercial Vehicles Second Edition. SAE International.

↩ -

Lakshminarayanan, P. A., & Kumar, A. (2020). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.