This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 4924718 O-Ring Seal, manufactured by Cummins, is a specialized component designed for use in commercial trucks. Cummins, a well-established name in the automotive industry, produces this O-Ring Seal to meet the demanding requirements of heavy-duty truck operations. This seal plays a role in the efficient and reliable performance of various systems within commercial trucks.

Basic Concepts of O-Ring Seals

An O-Ring Seal is a toroidal (ring-shaped) elastomer with a circular cross-section, used to create a seal between two or more parts. It functions by being compressed within a groove, creating a barrier that prevents the leakage of fluids or gases. O-Ring Seals are widely utilized in mechanical systems due to their simplicity, effectiveness, and versatility in various applications, including automotive, aerospace, and industrial machinery 1.

Purpose of the 4924718 O-Ring Seal in Truck Operations

This Cummins part is specifically designed to operate within the complex systems of commercial trucks. It is placed in critical areas where fluid or gas sealing is required to maintain system integrity and performance. This seal ensures that fluids such as engine oil, coolant, or hydraulic fluid remain contained within their respective systems, preventing leaks that could lead to system failure or inefficiency 2.

Key Features of the 4924718 O-Ring Seal

This part is engineered with specific design and material characteristics to withstand the rigorous conditions of heavy-duty truck applications. It is made from high-quality elastomer materials that offer resistance to high temperatures, pressure, and a variety of chemicals. These features make it suitable for use in environments where other seals might fail, ensuring long-term reliability and performance 3.

Benefits of Using the 4924718 O-Ring Seal

Utilizing this O-Ring Seal in commercial trucks offers several advantages. Its design contributes to improved sealing efficiency, which is vital for maintaining system performance and preventing leaks. Additionally, the seal’s durability and resistance to harsh conditions contribute to its longevity, reducing the need for frequent replacements. This reliability is particularly beneficial in demanding environments where downtime can be costly 4.

Installation Considerations

Proper installation of the 4924718 O-Ring Seal is crucial for ensuring its optimal performance and longevity. Best practices include ensuring the groove is clean and free of debris before installation, using the correct installation tools to avoid damaging the seal, and verifying that the seal is properly seated within the groove. Avoiding common pitfalls such as over-lubrication or incorrect sizing can prevent installation issues that may compromise the seal’s effectiveness.

Troubleshooting Common Issues

O-Ring Seals, including the 4924718, may encounter issues such as leaks or failures over time. Common problems can often be traced back to installation errors, environmental factors, or wear and tear. Troubleshooting steps may involve inspecting the seal and its groove for damage, ensuring proper installation, and assessing environmental conditions that may affect the seal’s performance. Addressing these issues promptly can help maintain system integrity and prevent more significant problems.

Maintenance Tips

Regular maintenance of the 4924718 O-Ring Seal is key to prolonging its service life and maintaining its effectiveness. This includes routine inspections for signs of wear or damage, cleaning the seal and its groove as needed, and replacing the seal according to manufacturer guidelines or when signs of degradation are observed. Adhering to these maintenance practices can help ensure the seal continues to perform reliably in demanding applications.

Cummins: Manufacturer Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and focus on meeting the needs of its customers have established it as a trusted name in the automotive and heavy-duty truck sectors.

Cummins O-Ring Seal 4924718 Compatibility with Engine Models

The O-Ring Seal part number 4924718, manufactured by Cummins, is designed to fit seamlessly within a variety of engine models. This seal is crucial for maintaining the integrity of the engine’s sealing system, ensuring that there are no leaks and that the engine operates efficiently.

QSK19 and QSK60 Series

The O-Ring Seal 4924718 is compatible with the QSK19 CM850 MCRS and QSK60 CM850 MCRS engines. These engines are part of the QSK series, known for their robust performance and reliability. The seal fits into specific areas where it provides a critical barrier against fluid leakage, ensuring the engine’s internal components remain protected.

QSK38 Series

For the QSK38 CM850 MCRS and QSK38 CM2150 MCRS engines, the O-Ring Seal 4924718 is also a perfect fit. These engines are part of the QSK38 series, which is designed for high-performance applications. The seal’s role in these engines is to maintain the seal in various critical areas, ensuring that the engine’s performance is not compromised by leaks.

QSK50 Series

The QSK50 CM2150 K107, QSK50 CM2150 MCRS, and QSK50 CM2350 K108 engines also benefit from the O-Ring Seal 4924718. These engines are part of the QSK50 series, which is known for its versatility and power. The seal is designed to fit into the specific sealing points of these engines, providing a reliable barrier against leaks and ensuring the engine operates at peak efficiency.

Each of these engines relies on the O-Ring Seal 4924718 to maintain its sealing integrity, ensuring that the engine’s performance is not compromised by leaks. This seal is a critical component in maintaining the reliability and efficiency of these engines.

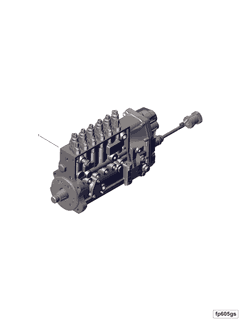

Role of Part 4924718 O-Ring Seal in Engine Systems

The part 4924718 O-Ring Seal is integral to maintaining the efficiency and reliability of various engine components. In the Fuel Injection Pump, this O-Ring Seal ensures a tight fit between moving parts, preventing fuel leaks and maintaining consistent fuel pressure. Its placement in the pump’s internal mechanisms helps in sealing dynamic interfaces, which is essential for the pump’s precise operation.

Within the Fuel Pump system, the O-Ring Seal plays a significant role in sealing connections between the pump housing and its various components. This seal is vital for maintaining the integrity of the fuel delivery system, ensuring that fuel is delivered without contamination or loss of pressure.

In general Pump applications, the 4924718 O-Ring Seal is used to create a reliable seal in areas where fluid dynamics and mechanical movement are present. This includes sealing points where the pump interacts with its mounting brackets or where fluid lines connect to the pump body.

Lastly, in the broader Fuel system, the O-Ring Seal is employed in various junctures to ensure that fuel lines, connectors, and fittings remain leak-free. This is particularly important in high-pressure fuel systems where even minor leaks can lead to significant performance issues or safety hazards. The seal’s ability to withstand varying temperatures and fuel types makes it a versatile component in ensuring the overall reliability of the fuel system.

Conclusion

The 4924718 O-Ring Seal by Cummins is a critical component in the maintenance and operation of commercial truck engines. Its design and material properties ensure it can withstand the harsh conditions of heavy-duty applications, providing reliable sealing across various engine systems. Proper installation, regular maintenance, and prompt troubleshooting of issues are essential to maximize the effectiveness and longevity of this seal, contributing to the overall performance and reliability of commercial trucks.

-

Lakshminarayanan, P. A., & Kumar, A. (2020). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature.

↩ -

Viskup, R. (2020). Diesel and Gasoline Engines. IntechOpen.

↩ -

Wright, G. (2015). Fundamentals of Medium-Heavy Duty Diesel Engines. Jones & Bartlett Learning.

↩ -

Hilgers, M., & Achenbach, W. (2021). Vocational Vehicles and Applications. Springer Vieweg.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.