This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4900292 O-Ring Seal is a critical component designed to maintain the integrity of fluid systems in heavy-duty trucks. Its primary function is to provide a reliable seal in various applications, contributing to the vehicle’s overall efficiency and performance. Understanding the role and significance of this part is essential for maintaining the operational standards of heavy-duty trucks.

Basic Concepts of O-Ring Seals

An O-Ring Seal is a type of gasket with a circular cross-section, designed to create a seal between two or more parts. It functions by deforming slightly when compressed between flanges or in a gland, creating a tight seal that prevents fluid or gas leakage. O-Rings are widely used in mechanical systems due to their simplicity, effectiveness, and versatility. They are commonly made from materials such as nitrile rubber, fluorocarbon, and silicone, each offering unique properties like resistance to chemicals, temperature extremes, and compression set 1.

Purpose of the 4900292 O-Ring Seal in Truck Operation

This Cummins part plays a specific role in the operation of heavy-duty trucks by ensuring the integrity of fluid systems. It is associated with components such as fuel injectors, where it helps maintain the seal around the injector body, preventing fuel leakage and ensuring efficient fuel delivery. Its functionality contributes to the overall performance and reliability of the truck’s engine system 2.

Key Features of the 4900292 O-Ring Seal

The 4900292 O-Ring Seal is characterized by its precise design and material composition, which enhances its performance and durability. Made from high-quality nitrile rubber, it offers excellent resistance to oils, fuels, and various chemicals commonly found in truck environments. Its unique characteristics include a specific durometer rating for optimal elasticity and sealing capability, ensuring it can withstand the dynamic conditions of heavy-duty truck operation 3.

Benefits of Using the 4900292 O-Ring Seal

Incorporating this part into truck maintenance routines offers several advantages. It provides improved sealing efficiency, reducing the risk of fluid leaks and enhancing system performance. Its durability and resistance to a wide range of operating conditions contribute to its longevity, making it a reliable component for heavy-duty applications. Additionally, its design ensures easy installation and replacement, minimizing downtime during maintenance procedures 4.

Installation and Replacement Guidelines

Proper installation and replacement of the 4900292 O-Ring Seal are crucial for ensuring optimal performance and longevity. Begin by cleaning the sealing area to remove any debris or old sealant. Inspect the O-Ring for any signs of damage before installation. When installing, avoid twisting or kinking the O-Ring, as this can compromise its sealing capability. Lubricate the O-Ring lightly with a compatible lubricant to facilitate installation and reduce friction. Ensure the O-Ring is seated correctly in its groove before assembling the components 5.

Troubleshooting Common Issues

Common problems associated with O-Ring Seals include leaks, extrusion, and compression set. To diagnose these issues, inspect the O-Ring for signs of wear, damage, or deformation. Addressing seal failure involves identifying the root cause, whether it be improper installation, material incompatibility, or excessive operating conditions. Preventive measures include regular inspection, proper installation techniques, and selecting the appropriate O-Ring material for the application 6.

Maintenance Tips

Regular maintenance of the 4900292 O-Ring Seal is key to ensuring its longevity and performance. Inspect the seal during routine maintenance checks for signs of wear or damage. Clean the O-Ring and its seating area to remove any contaminants that could affect its sealing capability. Conditions such as exposure to extreme temperatures, chemical exposure, or physical damage may necessitate early replacement of the O-Ring Seal to maintain system integrity 7.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established itself as a trusted provider of reliable components for the automotive industry, including heavy-duty trucks. Their commitment to excellence is reflected in the design and performance of components like the 4900292 O-Ring Seal, ensuring they meet the demanding requirements of heavy-duty applications 8.

Cummins O-Ring Seal 4900292 Compatibility with Engine Models

The Cummins O-Ring Seal part number 4900292 is designed to fit seamlessly with a range of Cummins engine models. Specifically, this O-Ring Seal is compatible with the following engines:

-

A1400 and A1700 Engines: These engines benefit from the O-Ring Seal 4900292 due to its precision fit and durability. This part ensures that the engine maintains optimal performance by preventing leaks and maintaining pressure integrity.

-

A2000 and A2300 Engines: Similarly, the A2000 and A2300 engines are engineered to work efficiently with the O-Ring Seal 4900292. This seal provides a reliable barrier against fluid leaks, ensuring the engine operates smoothly and efficiently.

The O-Ring Seal 4900292 is crafted to meet the stringent requirements of Cummins engines, ensuring that it provides a perfect seal in various operating conditions. Its compatibility with these engines underscores its importance in maintaining engine integrity and performance 9.

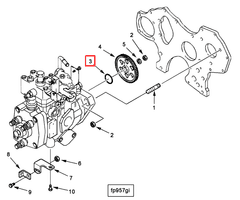

Role of Part 4900292 O-Ring Seal in Engine Systems

The 4900292 O-Ring Seal is instrumental in ensuring the integrity and efficiency of various engine systems. When integrated with the fuel pump mounting, this O-Ring Seal provides a tight and reliable seal between the fuel pump and its mounting surface. This seal is essential for preventing fuel leaks, maintaining fuel pressure, and ensuring that the fuel pump operates within specified parameters. The seal’s ability to conform to irregularities in the mounting surface enhances the overall stability and performance of the fuel pump.

In conjunction with the gasket set, the 4900292 O-Ring Seal plays a complementary role. While the gasket set typically addresses larger sealing surfaces and gaps, the O-Ring Seal focuses on smaller, more precise sealing requirements. Together, they create a comprehensive sealing solution that prevents fluid leakage, maintains system pressure, and protects sensitive engine components from contamination. This synergy ensures that the engine operates efficiently and reliably under various conditions 10.

Conclusion

The Cummins 4900292 O-Ring Seal is a vital component in maintaining the integrity and efficiency of fluid systems in heavy-duty trucks. Its precise design, durable material composition, and compatibility with various Cummins engine models make it an essential part for ensuring optimal engine performance. Regular maintenance and proper installation are key to maximizing the longevity and effectiveness of this part, contributing to the overall reliability and efficiency of heavy-duty truck operations.

-

Isermann, R. (2017). Combustion Engine Diagnosis. Springer Vieweg.

↩ -

Bonnick, A., & Newbold, D. (2011). A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition. Elsevier Ltd.

↩ -

Brown Jr, A. (2010). Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles. National Academy of Sciences.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 4383667.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 4383667.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 4383667.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 4383667.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 4383667.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 4383667.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 4383667.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.