This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 4331860 O-Ring Seal, manufactured by Cummins, is a specialized component designed for use in commercial trucks. Cummins, a well-established name in the commercial truck industry, produces a range of parts and systems that enhance the performance and reliability of heavy-duty vehicles. This part is integral to maintaining the integrity of various systems within these trucks, ensuring they operate efficiently and reliably.

Basic Concepts of O-Ring Seals

O-Ring Seals are elastomeric rings with a circular cross-section, used to create seals in both dynamic and static applications. They function by being compressed between two or more mating surfaces, thereby preventing the leakage of fluids or gases. In dynamic applications, O-Ring Seals accommodate movement while maintaining a seal, whereas in static applications, they provide a permanent seal between non-moving parts. Their effectiveness depends on factors such as material properties, design specifications, and the environmental conditions in which they operate 1.

Purpose of the 4331860 O-Ring Seal in Truck Operations

This Cummins part plays a specific role in the operation of commercial trucks by ensuring the integrity of seals in various systems. It is commonly used in fuel systems, hydraulic systems, and engine components where maintaining a reliable seal is crucial for performance and safety. By preventing leaks and ensuring proper system function, the 4331860 O-Ring Seal contributes to the overall efficiency and reliability of the truck 2.

Key Features of the 4331860 O-Ring Seal

The 4331860 is designed with specific features to meet the demands of heavy-duty applications. It is made from high-quality elastomeric materials that offer excellent resistance to oils, fuels, and other chemicals commonly found in truck systems. The seal is engineered to withstand high pressures and temperatures, ensuring durability and reliability in demanding environments. Its precise design specifications ensure a perfect fit in the intended applications, enhancing its effectiveness in creating and maintaining seals 3.

Benefits of Using the 4331860 O-Ring Seal

Utilizing this part in commercial trucks offers several advantages. Its robust construction and material properties contribute to improved reliability and longevity, reducing the need for frequent replacements. The seal’s ability to maintain effective seals under various conditions enhances the performance of the systems it supports, leading to more efficient truck operations. Additionally, the use of high-quality O-Ring Seals like the 4331860 can contribute to overall system integrity and safety.

Installation Considerations

Proper installation of the 4331860 is vital to ensure optimal performance and longevity. It is important to follow manufacturer guidelines for installation, including the use of the correct tools and techniques to avoid damaging the seal. Ensuring the mating surfaces are clean and free from debris is also crucial to maintain the integrity of the seal. Careful handling and installation can prevent common issues such as leaks and ensure the seal functions as intended.

Troubleshooting Common Issues

Common problems associated with O-Ring Seals include leaks, extrusion, and degradation. These issues can arise from improper installation, exposure to incompatible fluids, or excessive pressure and temperature conditions. Troubleshooting steps may involve inspecting the seal and mating surfaces for damage, ensuring proper installation techniques are used, and selecting the appropriate seal material for the application. Regular monitoring and maintenance can help identify and address issues before they lead to system failures.

Maintenance Tips

Regular maintenance practices can prolong the life of the 4331860. This includes routine inspections for signs of wear, damage, or degradation. Replacement guidelines should be followed to ensure seals are changed before they fail. Keeping the seal and mating surfaces clean and free from contaminants is also important. Additionally, monitoring system pressures and temperatures can help identify conditions that may affect seal performance, allowing for timely adjustments or replacements.

Cummins: A Brief Overview

Cummins is a leading manufacturer in the commercial truck industry, known for its wide range of engines, components, and systems. With a history of innovation and quality, Cummins has established a strong reputation for producing reliable and high-performance parts. Their product range includes engines, filtration systems, and aftermarket parts, all designed to enhance the efficiency, reliability, and performance of commercial trucks. Cummins’ commitment to quality and customer satisfaction has made them a preferred choice among truck operators and manufacturers.

Cummins O-Ring Seal 4331860 Compatibility

The O-Ring Seal part number 4331860, manufactured by Cummins, is designed to fit seamlessly within the engine systems of the QSK95 CM2350 K111 and QSK95 CM2350 K113 engines. This seal is crucial for maintaining the integrity of the engine’s sealing requirements, ensuring that there are no leaks and that the engine operates efficiently.

In the QSK95 CM2350 K111 and QSK95 CM2350 K113 engines, the O-Ring Seal 4331860 is strategically placed to prevent fluid or gas from escaping from the designated areas. Its precision fit ensures that it can withstand the high pressures and temperatures typical of these engine environments.

The seal’s material composition is engineered to provide durability and resistance to various engine fluids, which is essential for maintaining the longevity and performance of the engines. This compatibility is critical for the operational efficiency and safety of the engines, as it helps in maintaining the necessary pressure and preventing contamination.

By integrating the O-Ring Seal 4331860 into these engines, Cummins ensures that the seal meets the stringent requirements of the QSK95 CM2350 K111 and QSK95 CM2350 K113 models, providing a reliable sealing solution that enhances the overall performance and reliability of the engines.

Role of Part 4331860 O-Ring Seal in Engine Systems

The part 4331860 O-Ring Seal is integral to the functionality and efficiency of various engine components. Its primary role is to ensure a secure and leak-free seal in systems where fluid dynamics are essential.

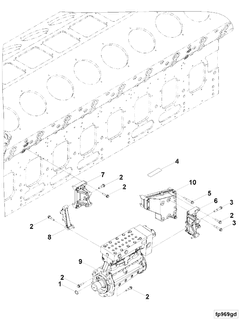

In the fuel system, the O-Ring Seal is employed to maintain the integrity of connections between the fuel pump and its associated components. This includes the fuel injection pump and the fuel filter. By providing a tight seal, it prevents fuel leaks, which can lead to inefficient fuel delivery and potential safety hazards.

Within the fuel injection pump, the O-Ring Seal is used at various connection points to ensure that pressurized fuel is delivered accurately to the engine’s combustion chambers. This precision is vital for optimal engine performance and fuel efficiency.

The fuel pump kit often incorporates the O-Ring Seal to secure the connections between the pump and the fuel lines. This ensures that the fuel is transported without loss, maintaining consistent pressure and flow rates necessary for reliable engine operation.

In the context of the mounting kit for fuel system components, the O-Ring Seal plays a role in securing the pump and other elements to the engine or chassis. This not only ensures a stable installation but also helps in preventing vibrations that could disrupt the fuel flow.

Overall, the part 4331860 O-Ring Seal is a small yet significant component that contributes to the seamless operation of the fuel system, enhancing both performance and safety.

Conclusion

The 4331860 O-Ring Seal by Cummins is a critical component in the maintenance and operation of commercial trucks. Its design and material properties ensure durability, reliability, and efficiency in various engine systems. Proper installation, regular maintenance, and understanding its role in engine systems are essential for maximizing the benefits of this part. Cummins’ commitment to quality and innovation continues to make the 4331860 O-Ring Seal a valuable asset in the commercial truck industry.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.