This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

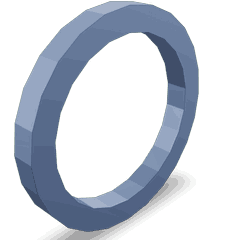

The Cummins 3974161 Rectangular Ring Seal is a component designed to ensure the integrity of seals within commercial truck systems. Its role is significant in maintaining the operational efficiency and reliability of trucks by preventing leaks and ensuring proper system function.

Basic Concepts of Rectangular Ring Seals

A Rectangular Ring Seal is a type of gasket that provides a seal between two or more parts in mechanical systems. It functions by filling the gap between mating surfaces, thereby preventing the escape of fluids or gases. These seals are commonly used in applications where a reliable and durable seal is required, such as in engines, transmissions, and hydraulic systems 1.

Purpose and Role in Truck Operation

This Cummins part plays a specific role in commercial truck operations by ensuring that seals within the engine and other systems remain intact. This contributes to the overall efficiency and reliability of the truck by preventing leaks that could lead to performance issues or system failures 2.

Key Features

This part is characterized by its material composition, typically made from durable elastomers or composite materials, which provide resistance to various operating conditions. Its design includes a rectangular cross-section that allows it to conform to irregular surfaces, enhancing its sealing capabilities. Unique attributes such as resistance to oil, heat, and abrasion further contribute to its performance 3.

Benefits

Using this part offers several benefits, including improved sealing efficiency, enhanced durability, and resistance to a range of operating conditions. These attributes help in maintaining the integrity of the seal over time, reducing the likelihood of leaks and contributing to the longevity of the truck’s systems 4.

Installation Process

Proper installation of this part involves several steps to ensure optimal performance. This includes cleaning the mating surfaces, inspecting the seal for any defects, and positioning it correctly within the system. Tools such as seal installation tools may be required to ensure the seal is seated properly without damage.

Troubleshooting Common Issues

Common problems associated with Rectangular Ring Seals include leaks, seal deformation, and failure due to wear or incorrect installation. Troubleshooting these issues may involve inspecting the seal and mating surfaces for damage, ensuring proper installation, and replacing the seal if necessary to restore system integrity.

Maintenance Tips

Regular maintenance practices can help prolong the lifespan of this Cummins part. This includes periodic inspection for signs of wear or damage, cleaning the mating surfaces to remove contaminants, and replacing the seal according to the manufacturer’s guidelines or when signs of degradation are observed.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a history of innovation and a strong reputation in the automotive and commercial truck industry, Cummins is known for producing high-quality components that enhance the performance and reliability of vehicles.

Compatibility of Rectangular Ring Seal Part 3974161 with Cummins Engines

The Rectangular Ring Seal part 3974161, manufactured by Cummins, is designed to fit seamlessly with a range of Cummins diesel engines. This part is crucial for ensuring the integrity of the engine’s sealing system, which is vital for maintaining optimal performance and efficiency.

Compatibility with Specific Engine Models

-

4B3.9 and 6B5.9 Engines This part is compatible with the 4B3.9 and 6B5.9 engines. These engines are part of the B Series family, known for their robust design and reliability in various industrial applications.

-

6C8.3 Engine This part also fits the 6C8.3 engine, which is another member of the C Series engines. The 6C8.3 is recognized for its high power output and durability, making it suitable for heavy-duty applications.

-

B4.5 Engine The Rectangular Ring Seal part 3974161 is also suitable for the B4.5 engine. This engine is part of the B Series and is often used in agricultural and construction equipment due to its balance of power and efficiency.

-

QSB3.9 30 CM550, QSB5.9 30 CM550, and QSB5.9 44 CM550 Engines This part is compatible with the QSB3.9 30 CM550, QSB5.9 30 CM550, and QSB5.9 44 CM550 engines. These engines are part of the QSB Series, which is known for its versatility and performance across various applications, including industrial, agricultural, and marine uses.

Grouping of Compatible Engines

The compatibility of the Rectangular Ring Seal part 3974161 with the listed engines can be grouped based on their series and applications:

-

B Series Engines (4B3.9, 6B5.9, B4.5) These engines are primarily used in industrial and agricultural sectors, where reliability and power are paramount.

-

C Series Engine (6C8.3) The 6C8.3 engine is designed for heavy-duty applications, providing robust performance in demanding environments.

-

QSB Series Engines (QSB3.9 30 CM550, QSB5.9 30 CM550, QSB5.9 44 CM550) These engines are versatile and used across various sectors, including industrial, agricultural, and marine applications, offering a balance of power, efficiency, and reliability.

Role of Part 3974161 Rectangular Ring Seal in Engine Systems

The Rectangular Ring Seal, identified as part 3974161, is an essential component in various engine systems, particularly within the fuel system. Its primary function is to ensure a secure and leak-free connection between different components, enhancing the overall efficiency and reliability of the engine.

Fuel System Integration

In the fuel system, the Rectangular Ring Seal is utilized to create a tight seal between the fuel filter and the fuel pump. This seal is vital for maintaining the integrity of the fuel flow, preventing any leaks that could lead to fuel loss or contamination. The seal ensures that the fuel transfer from the filter to the pump is smooth and uninterrupted, which is essential for consistent engine performance.

Fuel Transfer and Strainer Assembly

During fuel transfer, the Rectangular Ring Seal plays a significant role in connecting the strainer to the fuel lines. The strainer is responsible for filtering out impurities from the fuel before it reaches the engine. A secure seal here is necessary to prevent any bypass of contaminants, ensuring that only clean fuel is delivered to the engine components.

Accessories and Fuel Pump Connection

The seal is also employed in the connection between various accessories and the fuel pump. These accessories may include pressure regulators, fuel injectors, or other components that require a precise and leak-free connection to function correctly. The Rectangular Ring Seal ensures that these connections remain intact under varying pressure conditions, contributing to the stable operation of the fuel system.

Overall System Reliability

By providing a reliable seal in these critical connections, the Rectangular Ring Seal contributes to the overall reliability of the engine system. It helps maintain the necessary pressure within the fuel lines, ensures clean fuel delivery, and prevents leaks that could otherwise lead to engine malfunctions or decreased performance.

Conclusion

In summary, the Rectangular Ring Seal (part 3974161) is a fundamental component in ensuring the seamless operation of the fuel system, playing a key role in maintaining the efficiency and reliability of engine performance.

-

Vehicle Dynamics and Control, Rajesh Rajamani, Springer, 2005

↩ -

Systems Engineering for Automotive Powertrain Development, Hannes Hick, Klaus Kupper, and Helfried Sorger, Springer, 2021

↩ -

Haynes Manual on Diesel Engines, Martynn Randall, Haynes Publishing, 2015

↩ -

Internal Combustion Engine Fundamentals, John Heywood, McGraw-Hill Education, 2019

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.