This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3912818 O-Ring Seal is a component designed to ensure the integrity of fluid systems within commercial trucks. Its role is to prevent leaks and maintain system efficiency, contributing to the overall performance and reliability of the vehicle.

Basic Concepts of O-Ring Seals

An O-Ring Seal is a type of gasket made from a circular cross-section of elastomer material. It functions by creating a seal between two or more parts, typically in dynamic or static applications. O-Ring Seals are widely used in mechanical systems to prevent fluid or gas leakage, ensuring the system operates within specified parameters 1.

Purpose of the Cummins 3912818 O-Ring Seal

The Cummins 3912818 O-Ring Seal plays a specific role in the operation of a truck by sealing connections within the engine or other systems. It ensures that fluids such as oil, coolant, or fuel do not escape, which is vital for maintaining system pressure and efficiency. This seal is integral to the proper functioning of the truck’s engine and related systems.

Key Features

The Cummins 3912818 O-Ring Seal is characterized by its material composition, typically a durable elastomer that can withstand high temperatures and pressures. Its design specifications include precise dimensions to ensure a proper fit and effective seal. Unique attributes may include resistance to specific chemicals or enhanced flexibility for dynamic applications 2.

Benefits

Using the Cummins 3912818 O-Ring Seal provides several benefits, including improved sealing efficiency, which helps maintain system integrity and performance. Its durability ensures long-term reliability, while its resistance to various operating conditions contributes to the overall robustness of the truck’s systems.

Installation Considerations

When installing the Cummins 3912818 O-Ring Seal, it is important to follow guidelines and best practices. This includes proper handling to avoid damage, ensuring correct seating within the groove, and adhering to torque specifications where applicable to prevent over-tightening, which could compromise the seal.

Troubleshooting Common Issues

Common problems with O-Ring Seals may include leaks due to improper seating, damage during installation, or degradation over time. Troubleshooting methods involve inspecting the seal for signs of wear or damage, ensuring correct installation, and replacing the seal if necessary to resolve leakage issues.

Maintenance Tips

Regular maintenance of the Cummins 3912818 O-Ring Seal involves periodic inspection for signs of wear or damage. Cleaning procedures should be followed to remove any contaminants that could affect seal performance. Replacement guidelines suggest that the seal should be inspected and potentially replaced during routine maintenance intervals to ensure continued system integrity.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a diverse product range, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance components 3.

Cummins O-Ring Seal 3912818 Compatibility

The Cummins O-Ring Seal part number 3912818 is designed to fit a variety of Cummins engines, ensuring a reliable seal in various applications. Here is a detailed look at the compatibility of this part with specific engine models:

4B3.9 and 6B5.9 Engines

The O-Ring Seal 3912818 is compatible with the 4B3.9 and 6B5.9 engines. These engines are known for their robust design and are often used in heavy-duty applications. The seal ensures that the engine maintains its operational integrity by preventing leaks.

B3.9 G and B5.9 G Engines

The O-Ring Seal 3912818 is also suitable for the B3.9 G and B5.9 G engines. These engines are part of the B Series, which is recognized for its versatility and efficiency in various industrial and commercial applications. The seal plays a role in maintaining the pressure and preventing fluid leaks within the engine system.

B5.9 GAS PLUS CM556 Engine

For the B5.9 GAS PLUS CM556 engine, the O-Ring Seal 3912818 is a component. This engine is designed for natural gas applications, providing a cleaner and more efficient alternative to diesel. The seal ensures that the engine operates smoothly by maintaining the necessary seals and preventing gas leaks.

G5.9 Engine

The G5.9 engine is another model where the O-Ring Seal 3912818 is applicable. This engine is part of the G Series, known for its reliability and performance in various applications. The seal is crucial in maintaining the engine’s efficiency and preventing any leaks that could compromise its performance.

ISB CM850, ISB5.9G CM2180, and QSB5.9 CM850 Engines

The O-Ring Seal 3912818 is compatible with the ISB CM850, ISB5.9G CM2180, and QSB5.9 CM850 engines. These engines are part of the ISB and QSB Series, which are known for their power and reliability in heavy-duty applications. The seal ensures that these engines maintain their operational integrity by preventing leaks and maintaining pressure within the system.

By ensuring a proper fit and reliable seal, the Cummins O-Ring Seal 3912818 is a component for maintaining the performance and longevity of these engines.

Role of Part 3912818 O-Ring Seal in Engine Systems

The O-Ring Seal, identified by part number 3912818, is integral to maintaining the integrity and efficiency of various engine systems. Its application spans across several key components, ensuring that each system operates within optimal parameters.

Crankcase Breather

In the crankcase breather system, the O-Ring Seal is employed to create a tight seal between the breather housing and the engine block. This seal is essential for preventing the escape of crankcase vapors, which contain unburned fuel and combustion byproducts, into the atmosphere. By maintaining a sealed environment, the O-Ring contributes to reducing emissions and preserving the cleanliness of the engine’s internal components.

Engine Oil Cooler

Within the engine oil cooler setup, the O-Ring Seal is utilized at the connection points between the cooler and the oil lines. This ensures that the oil flow remains uninterrupted and free from contamination. The seal prevents oil leaks, which could lead to a decrease in oil pressure and subsequent engine damage. Moreover, it helps in maintaining the efficiency of the cooling process, thereby protecting the engine from overheating.

Fuel Filter and Fuel Filter Plumbing

For the fuel filter and its associated plumbing, the O-Ring Seal plays a pivotal role in ensuring that the fuel system remains pressurized and free from leaks. It seals the connections between the fuel filter housing and the fuel lines, as well as within the plumbing components. This is vital for maintaining the correct fuel pressure, which is necessary for efficient combustion and engine performance.

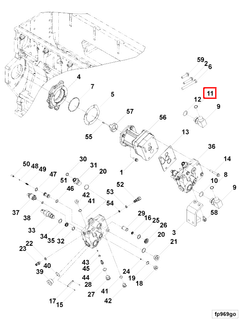

Fuel Injection Pump

In the fuel injection pump, the O-Ring Seal is critical for sealing the connections between the pump and the fuel lines. This ensures that the fuel delivery system operates under the precise pressure required for optimal injection timing and fuel atomization. A secure seal prevents fuel leaks, which could otherwise lead to inefficient fuel consumption and potential fire hazards.

Fuel Pump

The O-Ring Seal is also utilized in the fuel pump assembly, particularly at the points where the pump connects to the fuel lines and the fuel tank. This seal is essential for maintaining the integrity of the fuel system, ensuring that fuel is delivered to the engine without leaks or pressure drops. It also plays a role in preventing the ingress of contaminants into the fuel system, which could damage the fuel pump and injectors.

Full Flow Oil Filter

In the full flow oil filter system, the O-Ring Seal is used to ensure a tight connection between the filter housing and the engine block or the oil lines. This seal is vital for maintaining the oil filtration process, ensuring that contaminants are effectively removed from the oil before it circulates through the engine. A secure seal prevents oil bypass, which could lead to reduced filtration efficiency and increased engine wear.

Plain Union Elbow

Lastly, in the plain union elbow components, the O-Ring Seal is employed to create a leak-proof connection between the elbow and the adjoining pipes or fittings. This is particularly important in systems where fluid dynamics and pressure maintenance are crucial, such as in the fuel and oil systems. The seal ensures that the system remains pressurized and free from leaks, contributing to the overall efficiency and reliability of the engine.

Conclusion

The Cummins 3912818 O-Ring Seal is a critical component in maintaining the integrity and efficiency of various engine systems in commercial trucks. Its application across different engine models and components ensures that each system operates within optimal parameters, contributing to the overall performance and reliability of the vehicle. Regular maintenance and proper installation of this part are essential to ensure continued system integrity and prevent potential issues related to fluid leaks.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.