This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3684088 O-Ring Seal is a component designed to ensure the integrity of fluid systems within commercial trucks. Its role is to provide a reliable seal in various applications, contributing to the efficient operation of the vehicle. Understanding its purpose and significance is key to maintaining the performance and reliability of commercial trucks.

Basic Concepts of O-Ring Seals

An O-Ring Seal is a toroidal (ring-shaped) elastomer with a circular cross-section, used to create a seal between two or more parts. It functions by being compressed within a groove, creating a barrier that prevents the leakage of fluids or gases. O-Ring Seals are widely utilized in mechanical systems for their simplicity, effectiveness, and versatility in sealing applications 1.

Purpose of the 3684088 O-Ring Seal in Truck Operation

This Cummins part plays a specific role in the operation of commercial trucks by ensuring the integrity of seals in various fluid systems. It is typically located in areas where fluid transfer occurs, such as in the engine or transmission systems. Its function is to prevent leaks, maintain system pressure, and ensure the efficient operation of the truck’s systems.

Key Features of the 3684088 O-Ring Seal

The design and material characteristics of the 3684088 O-Ring Seal contribute to its effectiveness and durability. Made from high-quality elastomer materials, it is designed to withstand a range of temperatures and pressures. Its precise dimensions ensure a snug fit within the designated grooves, enhancing its sealing capabilities.

Benefits of Using the 3684088 O-Ring Seal

This part offers several advantages, including improved sealing performance, longevity, and resistance to various environmental factors. Its design allows for reliable operation under demanding conditions, reducing the risk of leaks and system failures. Additionally, its durability contributes to the overall efficiency and reliability of the truck’s systems.

Installation Considerations

Proper installation of the 3684088 O-Ring Seal is crucial for ensuring optimal performance and longevity. Guidelines for installation include ensuring the groove is clean and free of debris, using the correct lubrication during installation, and avoiding damage to the O-Ring during the process. Following these best practices helps maintain the integrity of the seal and the efficiency of the system.

Troubleshooting Common Issues

Common problems associated with O-Ring Seals include leaks, degradation, and improper seating. Troubleshooting steps may involve inspecting the O-Ring for signs of wear or damage, checking the condition of the groove, and ensuring proper installation techniques were followed. Addressing these issues promptly can help maintain the reliability of the sealing system.

Maintenance Tips

Regular maintenance of the 3684088 O-Ring Seal is recommended to prolong its service life and ensure continued reliable performance. This includes periodic inspection for signs of wear or damage, cleaning the groove and surrounding areas, and replacing the O-Ring as needed. Adhering to these maintenance practices contributes to the overall efficiency and reliability of the truck’s systems.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a commitment to quality and innovation, Cummins serves customers in approximately 190 countries and territories, providing reliable and efficient power solutions for various applications, including commercial trucks.

Cummins Engine O-Ring Seal 3684088 Compatibility

The O-Ring Seal part number 3684088, manufactured by Cummins, is a crucial component in ensuring the integrity and performance of various engine systems. This seal is designed to fit seamlessly within the engine architecture, providing a reliable barrier against leaks and maintaining system pressure. Below is a detailed description of its compatibility with the listed engines:

B6.7 Series Engines

- B6.7 CM2670 B153B

- B6.7 CM2670 B164C

- ISB6.7 CM2350 B101

- QSB6.7 CM2250

- QSB6.7 CM2350 B105

- QSB6.7 CM850 (CM2850)

- QSB6.7 M CM2250

- QSK19 CM2350 K105

- QSK19 CM2350 K114

- QSK50 CM2350 K108

The O-Ring Seal 3684088 is compatible with the B6.7 series engines, which include both the CM2670 and CM2350 variants. These engines are known for their robust design and are used in a variety of applications, from heavy-duty trucks to industrial machinery. The seal ensures that the engine’s internal components remain protected from contaminants and pressure loss.

F Series Engines

- F3.8 CM2620 F137B

- F4.5 CM2620 F139B

The F series engines, specifically the F3.8 and F4.5 variants, also benefit from the O-Ring Seal 3684088. These engines are designed for applications requiring high power and efficiency, such as construction and agricultural equipment. The seal’s precision fit helps maintain the engine’s performance and longevity.

ISX Series Engines

- ISX CM871

- ISX15 CM2350 X101

The ISX series engines, including the ISX CM871 and ISX15 CM2350 X101, are equipped with the O-Ring Seal 3684088. These engines are known for their high torque and reliability, making them ideal for long-haul trucking and other demanding applications. The seal ensures that the engine’s critical components are protected from leaks and pressure fluctuations.

QSB Series Engines

- QSB6.7 CM2350 B105

- QSB6.7 CM850 (CM2850)

- QSB6.7 M CM2250

- QSB7 CM2880 B117

The QSB series engines, such as the QSB6.7 and QSB7 variants, are designed for a wide range of applications, from construction to marine use. The O-Ring Seal 3684088 is essential for maintaining the engine’s performance and reliability in these demanding environments.

QSF Series Engines

- QSF2.8 CM2880 F104

- QSF2.8 CM2880 F105

- QSF2.8 CM2880 F108

- QSF2.8 CM2880 F114

The QSF series engines, including the QSF2.8 variants, are used in various industrial applications. The O-Ring Seal 3684088 ensures that these engines operate efficiently and reliably, providing the necessary sealing to prevent leaks and maintain system integrity.

X Series Engines

- X12 CM2350 X119B

- X15 CM2350 X116B

- X15 CM2350 X123B

- X15 CM2450 X134B

The X series engines, such as the X12 and X15 variants, are designed for heavy-duty applications. The O-Ring Seal 3684088 is a critical component in these engines, ensuring that they can withstand the rigors of demanding environments while maintaining optimal performance and reliability.

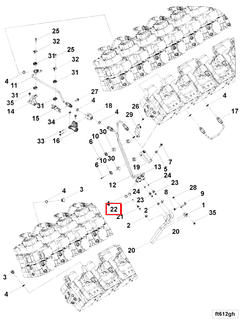

Role of Part 3684088 O-Ring Seal in Engine Systems

This part is integral to maintaining the integrity and efficiency of various engine systems. It is employed in multiple components to ensure proper sealing, preventing leaks and maintaining system pressure.

Fuel System Applications

In the fuel system, the O-Ring Seal is used in the fuel transfer pump to create a tight seal between the pump housing and the cover, ensuring no fuel escapes. It is also found in the fuel filter and fuel manifold where it seals connections, preventing fuel leakage and ensuring consistent fuel delivery to the engine.

The fuel drain plumbing and fuel supply plumbing utilize the O-Ring Seal to maintain a secure connection at various joints and fittings, such as the male connector and male union elbow. This ensures that fuel lines remain pressurized and free from leaks.

Oil System Applications

Within the oil system, the O-Ring Seal plays a significant role in components like the oil pan and thermostat housing. In the oil pan, it seals the connection points, such as those found in the thermostat housing assembly, to prevent oil leaks and maintain oil pressure.

The oil level gauge often incorporates the O-Ring Seal to ensure accurate readings by preventing oil from seeping past the gauge mechanism. Additionally, it is used in the lower engine gasket kit to seal various engine block connections, ensuring the oil remains contained within the system.

Additional System Applications

The breather system, which allows air to escape from the crankcase while preventing contaminants from entering, uses the O-Ring Seal to ensure a tight fit around the breather cap and other connection points.

In the doser system, which is part of emissions control, the O-Ring Seal ensures that the dosing fluid is delivered accurately without leaks, maintaining the efficiency of the emissions reduction process.

The hardware certification kit and injector spray tester also benefit from the O-Ring Seal, ensuring that these tools function correctly without fluid leaks, which could otherwise skew test results or damage sensitive components.

Turbocharger and Plumbing Applications

The turbocharger system relies on the O-Ring Seal to maintain the integrity of connections in the plumbing that carries fluid to and from the turbocharger. This includes sealing the quick disconnect connector and various joints in the plain hose coupling to ensure consistent turbocharger performance and prevent fluid leaks.

Conclusion

In summary, the 3684088 O-Ring Seal is a versatile component that enhances the reliability and performance of various engine systems by ensuring secure, leak-free connections. Its role in preventing leaks, maintaining system pressure, and ensuring the efficient operation of commercial trucks underscores its importance in the maintenance and reliability of these vehicles.

-

Heywood, J. (2019). Internal Combustion Engine Fundamentals. McGraw-Hill Education.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.