This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Rectangular Ring Seal, part number 3678536, manufactured by Cummins, is a component designed to maintain system integrity in commercial truck operations. This seal plays a role in preventing leaks and ensuring the efficient operation of various truck systems.

Basic Concepts of Rectangular Ring Seals

A Rectangular Ring Seal is a type of gasket that provides a seal between two or more parts. It functions by creating a barrier that prevents the escape of fluids or gases. These seals are typically made from materials such as rubber, silicone, or other elastomers, chosen for their flexibility and ability to conform to irregular surfaces 1. The sealing mechanism relies on the compression of the seal between mating surfaces, which creates a tight fit that resists leakage.

Purpose of the 3678536 Rectangular Ring Seal in Truck Operations

The 3678536 Rectangular Ring Seal is utilized in various systems within commercial trucks, including fuel systems, hydraulic systems, and engine compartments. Its role is to ensure that fluids and gases remain contained within their designated pathways, which is vital for the proper functioning of these systems. By maintaining a secure seal, it helps in preserving the efficiency and reliability of the truck’s operations 2.

Key Features of the 3678536 Rectangular Ring Seal

The 3678536 Rectangular Ring Seal is characterized by its rectangular cross-section, which allows it to fit into grooves and provide a robust seal. The material properties of this seal, typically a durable elastomer, contribute to its ability to withstand high pressures and temperatures commonly encountered in truck environments. Additionally, its design ensures easy installation and removal, facilitating maintenance procedures.

Benefits of Using the 3678536 Rectangular Ring Seal

Utilizing the 3678536 Rectangular Ring Seal offers several advantages. It provides enhanced sealing efficiency, which is crucial in preventing leaks that could lead to system failures. The seal’s durability ensures long-term performance, even under demanding conditions. Moreover, its reliability contributes to the overall safety and efficiency of truck operations.

Installation Considerations

Proper installation of the 3678536 Rectangular Ring Seal is key to ensuring its optimal performance. It is important to follow manufacturer guidelines, which may include cleaning the sealing surfaces, using the correct amount of lubrication, and ensuring that the seal is properly seated in its groove. Attention to these details helps in achieving a secure and effective seal 3.

Maintenance and Troubleshooting

Routine maintenance of the 3678536 Rectangular Ring Seal involves inspecting it for signs of wear or damage during regular service intervals. If leaks are detected, the seal should be examined for proper seating and condition. Troubleshooting may involve checking for misalignments or debris that could affect the seal’s performance. Replacing the seal when necessary ensures continued reliable operation.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established a strong reputation in the commercial truck industry. The company’s product portfolio includes a wide range of components and systems that contribute to the efficiency and reliability of trucks worldwide.

Cummins Rectangular Ring Seal (Part 3678536) Compatibility with Various ISX and QSX Engines

The Cummins Rectangular Ring Seal, identified by part number 3678536, is a critical component in maintaining the integrity of various ISX and QSX engine models. This seal is designed to fit seamlessly within the engine’s architecture, ensuring optimal performance and longevity.

ISX Engine Series

- ISX CM570

- ISX CM870

- ISX CM871

- ISX15 CM2250

- ISX15 CM2250 SN

- ISX15 CM2350 X101

The ISX engine series, including the CM570, CM870, CM871, ISX15 CM2250, ISX15 CM2250 SN, and ISX15 CM2350 X101, all benefit from the precise fit and functionality of the 3678536 seal. This seal is engineered to withstand the high pressures and temperatures inherent in these engines, ensuring that there are no leaks or inefficiencies in the system.

QSX Engine Series

- QSX15 CM2250

- QSX15 CM2250 ECF

- QSX15 CM2350 X105

Similarly, the QSX engine series, which includes the QSX15 CM2250, QSX15 CM2250 ECF, and QSX15 CM2350 X105, also incorporates the 3678536 seal. This seal is designed to fit perfectly within the QSX engines, providing a reliable barrier against oil and other fluids, which is crucial for maintaining engine efficiency and preventing contamination.

By ensuring a proper fit and function, the 3678536 seal contributes to the overall reliability and performance of both the ISX and QSX engine series. Its design and material composition are tailored to meet the specific demands of these engines, making it an essential component for technicians and engineers working with these models.

Role of Part 3678536 Rectangular Ring Seal in Engine Systems

The Part 3678536 Rectangular Ring Seal is integral to maintaining the efficiency and reliability of various engine components. Its primary function is to ensure a secure and leak-free seal between moving and stationary parts within the engine system.

In the context of the Connecting Rod and Piston assembly, the Rectangular Ring Seal helps to maintain the integrity of the lubrication system. It prevents oil from leaking out of the connecting rod bearings, ensuring that the piston receives consistent lubrication. This is essential for reducing friction and wear on the piston and connecting rod interface.

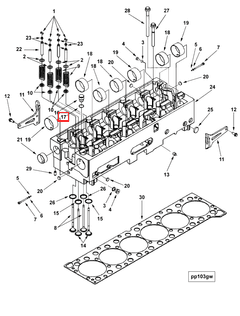

When considering the Cylinder Head and the Cylinder Head Rebuild Kit, the seal plays a role in maintaining the compression within the combustion chamber. By sealing the gaps between the cylinder head and the engine block, it ensures that the air-fuel mixture remains contained during the combustion process, leading to more efficient engine performance.

In the Cylinder Top Level Assembly Head, the Rectangular Ring Seal assists in keeping the sealing surfaces tight. This is particularly important during reassembly after a rebuild, where precise fitting is required to avoid leaks and ensure optimal engine function.

For the Engine Piston and the Head, the seal is used to maintain the pressure differentials necessary for efficient operation. It ensures that the piston rings seal against the cylinder walls effectively, preventing blow-by—where combustion gases escape past the piston rings.

In the Cylinder RA (presumably referring to the cylinder block or related assembly), the seal contributes to the overall structural integrity by preventing fluid leaks that could compromise the engine’s lubrication and cooling systems.

The Injector and Injector Sleeve also benefit from the use of this seal. It ensures that the fuel delivery system remains pressurized and leak-free, which is vital for precise fuel injection and combustion efficiency.

Lastly, in the realm of Performance Parts, the Rectangular Ring Seal is often utilized in aftermarket upgrades to maintain the heightened performance standards. Whether it’s in high-performance cylinder heads or custom piston designs, the seal ensures that all components work in unison without unwanted leaks or losses in pressure.

Conclusion

The 3678536 Rectangular Ring Seal is a vital component in the maintenance and operation of commercial truck engines. Its role in preventing leaks, ensuring efficient operation, and contributing to the overall reliability of truck systems cannot be overstated. Proper installation, maintenance, and understanding of its compatibility with various engine models are essential for maximizing its benefits and ensuring the longevity and performance of the engines it serves.

-

Composite Materials Handbook Volume 4 Metal Matrix Composites, SAE International, 2013.

↩ -

Mobile Equipment Hydraulics A Systems and Troubleshooting Approach, Ben Watson, Cengage Learning, 2011.

↩ -

SAE International’s Dictionary of Testing, Verification and Validation, Jon M. Quigley, SAE International, 2023.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.