This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3606650 O-Ring Seal is a critical component designed to maintain the integrity of seals in various applications within heavy-duty trucks. Its role is essential in ensuring the efficiency and reliability of truck operations. This seal is part of a broader system that requires precise components to function correctly, underscoring the importance of each part in the overall performance of heavy-duty vehicles.

Basic Concepts of O-Ring Seals

An O-Ring Seal is a type of gasket with a circular cross-section, designed to create a seal between two or more parts. It functions by being compressed within a groove, creating a barrier that prevents the leakage of fluids or gases. O-Ring Seals are widely used in mechanical systems due to their simplicity, effectiveness, and versatility. They are commonly made from materials such as nitrile rubber, fluorocarbon, and silicone, each offering different properties like resistance to chemicals, temperature, and pressure 1.

Purpose of the 3606650 O-Ring Seal in Truck Operation

The 3606650 O-Ring Seal plays a specific role in the operation of heavy-duty trucks by ensuring the integrity of seals in systems where fluid or gas containment is required. It is associated with components that demand reliable sealing to maintain system efficiency and prevent leaks. By providing a secure seal, it contributes to the functionality and longevity of the associated systems 2.

Key Features of the 3606650 O-Ring Seal

The 3606650 O-Ring Seal is designed with features that make it suitable for demanding applications in heavy-duty trucks. Its construction ensures durability and resistance to various conditions, including exposure to chemicals, high temperatures, and pressure fluctuations. Compatibility with other parts is ensured through precise manufacturing standards, allowing it to integrate seamlessly into existing systems 3.

Benefits of Using the 3606650 O-Ring Seal

Utilizing the 3606650 O-Ring Seal offers several advantages, including improved sealing efficiency, enhanced longevity, and increased reliability of the systems it is part of. Compared to other types of seals, it provides a cost-effective solution that requires minimal maintenance while offering superior performance in challenging environments.

Installation and Maintenance Guidelines

Proper installation of the 3606650 O-Ring Seal involves ensuring the groove is clean and free of debris before placing the seal. It should be lubricated to facilitate installation and prevent damage. Regular maintenance checks are recommended to ensure the seal remains in good condition, with any signs of wear or damage addressed promptly to maintain optimal performance.

Troubleshooting Common Issues

Common issues with O-Ring Seals, including the 3606650 model, may involve leaks, wear, or failure due to environmental factors or improper installation. Diagnostic procedures should include a thorough inspection of the seal and its groove for any signs of damage or misalignment. Solutions may range from simple replacements to addressing underlying issues that contribute to seal failure.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins plays a significant role in the automotive and heavy-duty truck industry. The company’s commitment to excellence is evident in its product line, including components like the 3606650 O-Ring Seal, which are designed to meet the rigorous demands of heavy-duty applications.

Cummins O-Ring Seal Part 3606650 Compatibility with Engine Models

The Cummins O-Ring Seal part number 3606650 is designed to fit seamlessly within various engine models, ensuring optimal sealing and performance. This seal is crucial for maintaining the integrity of the engine’s systems by preventing leaks and ensuring that the engine operates efficiently.

L10 GAS

The L10 GAS engine benefits from the precision fit of the 3606650 O-Ring Seal. This seal is engineered to withstand the specific pressures and temperatures encountered in the L10 GAS engine, ensuring that it performs reliably over time.

QSK19G and QSV81G

The QSK19G and QSV81G engines also utilize the 3606650 O-Ring Seal. These engines, known for their robust performance, require high-quality seals to maintain their operational efficiency. The 3606650 O-Ring Seal is designed to fit perfectly within these engines, providing a tight seal that prevents leaks and ensures the engine operates smoothly.

QSV91G

Similarly, the QSV91G engine incorporates the 3606650 O-Ring Seal. This seal is critical for maintaining the engine’s performance, as it ensures that there are no leaks in the system. The 3606650 O-Ring Seal is made from high-quality materials that can withstand the demanding conditions of the QSV91G engine.

By using the 3606650 O-Ring Seal in these engines, technicians and operators can be confident that their engines will perform optimally and reliably. This seal is a vital component that ensures the longevity and efficiency of the engine systems.

Role of Part 3606650 O-Ring Seal in Engine Systems

The O-Ring Seal, identified by part number 3606650, is integral to the efficient operation of various engine components. Its primary function is to ensure a secure and leak-proof seal between mating surfaces, which is essential for maintaining the integrity of the fuel and gas systems within an engine.

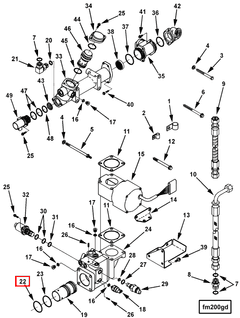

In the Air Fuel Mixer, the O-Ring Seal is positioned to prevent any leakage of air or fuel at the connection points. This ensures that the mixture entering the combustion chamber is precisely controlled, contributing to optimal engine performance and fuel efficiency.

Within the Assembly Control Fuel and Fuel Control Module, the O-Ring Seal plays a significant role in maintaining the pressure and flow of fuel. By sealing the connections and interfaces, it prevents fuel leakage, which could otherwise lead to inefficient combustion and potential safety hazards.

For the Gas Module P=1,25bar and Gas Module P=1,8bar, the O-Ring Seal is essential for maintaining the specified gas pressure. These modules require precise pressure control to function correctly, and the seal ensures that there are no pressure drops or leaks that could affect performance.

In the Module P=3bar Gas, the O-Ring Seal is similarly important. It ensures that the higher pressure gas is contained within the system, allowing for efficient and reliable operation of the gas delivery components.

Overall, the O-Ring Seal (part 3606650) is a fundamental component in these engine systems, providing the necessary seals to maintain pressure, prevent leaks, and ensure the efficient and safe operation of fuel and gas modules.

Conclusion

The 3606650 O-Ring Seal by Cummins is a vital component in the maintenance and operation of heavy-duty trucks. Its role in ensuring the integrity of seals within various engine systems cannot be overstated. By providing a secure and leak-proof seal, this Cummins part contributes to the efficiency, reliability, and longevity of the truck’s engine systems. Proper installation, regular maintenance, and prompt troubleshooting of common issues are essential to maximize the benefits of using this O-Ring Seal.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.