This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3606607 O-Ring Seal is a critical component for maintaining the integrity of fluid systems in commercial trucks. This part ensures reliable sealing in various applications, contributing to the efficient operation and longevity of truck systems by preventing leaks and ensuring proper fluid dynamics 1.

Basic Concepts of O-Ring Seals

O-Ring Seals are elastomeric rings with a circular cross-section, designed to create a seal between two or more parts. They function by being compressed within a groove, forming a barrier that prevents the escape of fluids or gases. These seals are widely utilized in mechanical systems for their simplicity, effectiveness, and versatility in applications including automotive, aerospace, and industrial machinery 2.

Purpose of the Cummins 3606607 O-Ring Seal

The Cummins 3606607 O-Ring Seal is specifically designed for sealing mechanisms in truck systems. It is placed in grooves within components where fluid transfer occurs, maintaining a tight barrier to ensure that fluids such as oil, coolant, or hydraulic fluid remain contained within their designated pathways. This helps preserve the operational efficiency and reliability of the truck’s systems 3.

Key Features

This Cummins part is characterized by its material composition, typically made from durable elastomers such as nitrile or fluorocarbon, which offer resistance to various chemicals and temperatures. Its design specifications include precise dimensions to fit specific grooves and applications, ensuring a snug fit and effective sealing. Unique characteristics may include enhanced flexibility, resistance to compression set, and compatibility with a range of fluids.

Benefits of Using the Cummins 3606607 O-Ring Seal

Utilizing this part offers several advantages. It provides improved sealing efficiency, reducing the risk of leaks that can lead to system failures or inefficiencies. The seal’s durability ensures long-term performance, even under harsh operating conditions typical of commercial truck environments. Its reliability contributes to the overall dependability of the truck’s systems, minimizing downtime and maintenance costs.

Installation and Maintenance

Proper installation of the Cummins 3606607 O-Ring Seal involves preparing the surfaces to ensure they are clean and free of debris. The use of appropriate tools is recommended to avoid damaging the seal during installation. Maintenance tips include regular inspection for signs of wear or degradation, and replacement as necessary to ensure continued optimal performance. Following manufacturer guidelines for installation and maintenance can help extend the lifespan of the seal and the systems it protects.

Troubleshooting Common Issues

Common problems associated with O-Ring Seals, such as leaks or failures, can often be traced back to improper installation, degradation due to exposure to incompatible fluids or temperatures, or physical damage. Troubleshooting steps may involve inspecting the seal and its groove for damage, ensuring proper fit and compression, and verifying compatibility with system fluids and operating conditions. Addressing these issues promptly can help maintain the integrity of the truck’s systems.

Compatibility and Application

The Cummins 3606607 O-Ring Seal is designed for specific applications within truck systems, ensuring compatibility with various components and fluids. Its application is tailored to meet the demands of commercial truck operations, providing a reliable sealing solution in environments where durability and performance are paramount.

Safety Considerations

When handling, installing, or maintaining the Cummins 3606607 O-Ring Seal, it is important to observe safety practices to ensure personal safety and component integrity. This includes wearing appropriate personal protective equipment, following manufacturer guidelines for installation and maintenance, and being aware of the properties of the fluids and environments the seal will encounter.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction, providing reliable and efficient products that meet the demanding needs of commercial vehicle operators.

Cummins O-Ring Seal 3606607 Compatibility with Engine Models

The Cummins O-Ring Seal part number 3606607 is designed to fit seamlessly within several of Cummins’ engine models. This seal is crucial for maintaining the integrity of various engine components by preventing leaks and ensuring that the engine operates efficiently. Below are the specific engine models where this seal is applicable:

L10 GAS

The L10 GAS engine benefits from the O-Ring Seal 3606607 in its sealing applications. This seal ensures that the engine’s performance is not compromised by any leaks, maintaining optimal pressure and efficiency.

QSC8.3 CM850 (CM2850)

In the QSC8.3 CM850 (CM2850) engine, the O-Ring Seal 3606607 plays a vital role in sealing critical components. Its precision fit helps in maintaining the engine’s operational integrity and preventing any potential fluid leaks.

QSK60 CM850 MCRS

The QSK60 CM850 MCRS engine also utilizes the O-Ring Seal 3606607. This seal is essential for ensuring that the engine’s components remain sealed, thereby enhancing the overall performance and reliability of the engine.

Grouping of Engines

The O-Ring Seal 3606607 is compatible with both the QSC8.3 CM850 (CM2850) and the QSK60 CM850 MCRS engines, which share similar sealing requirements due to their design and operational parameters. This commonality allows for easier maintenance and part replacement across these engine models.

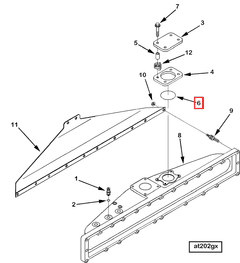

Role of Part 3606607 O-Ring Seal in Engine Systems

The Part 3606607 O-Ring Seal is integral to the efficient operation of various engine components. It ensures the sealing integrity between mating surfaces, preventing leaks and maintaining system performance.

Fuel System Integration

In the fuel system, the O-Ring Seal is employed in the fuel injector and the fuel top-level assembly injector. Its role here is to create a tight seal, ensuring that fuel is delivered precisely and without leakage. This precision is essential for optimal combustion and overall engine performance.

Turbocharger Application

Within the turbocharger arrangement, the O-Ring Seal is used to maintain the integrity of the compressed air flow. By sealing the connections between the turbocharger components, it helps in sustaining the required pressure levels, which are vital for enhanced engine performance.

Heat Exchanger Functionality

The heat exchanger relies on the O-Ring Seal to prevent coolant or other fluids from leaking out. This seal ensures that the heat transfer process between the engine and the cooling system remains efficient, contributing to the engine’s thermal management.

General Component Sealing

Across various engine parts, the O-Ring Seal plays a consistent role in preventing fluid and gas leaks. Its application in different components ensures that the engine operates within specified parameters, enhancing durability and reliability.

Conclusion

The Cummins 3606607 O-Ring Seal is a vital component in the maintenance and operation of commercial truck systems. Its role in preventing leaks, ensuring fluid dynamics, and contributing to the overall efficiency and reliability of truck engines cannot be overstated. Proper installation, maintenance, and understanding of its applications are key to maximizing the benefits of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.