This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

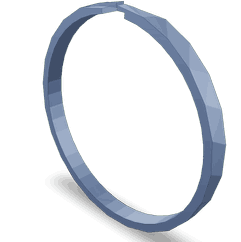

The Cummins 3523412 Split Ring Seal is designed to enhance the operational efficiency of commercial trucks by providing a reliable seal in various mechanical systems. This ensures that fluids and pressures are maintained within the desired parameters, contributing to the overall performance and longevity of truck engines and transmissions.

Basic Concepts of Split Ring Seals

Split ring seals are mechanical components used to create a seal between two surfaces. They function by being compressed between a static and a dynamic part, thereby preventing leakage of fluids or gases. These seals are commonly applied in engines, transmissions, and other systems where maintaining pressure and preventing leaks is necessary for optimal performance 1.

Purpose of the Cummins 3523412 Split Ring Seal

The Cummins 3523412 Split Ring Seal is specifically engineered to serve within the engine or transmission system of a truck. It ensures that the seals between moving parts are maintained, which is vital for the efficient operation of these systems. By preventing leaks, it helps in maintaining the integrity of the system’s pressure and fluid levels, thereby contributing to the smooth functioning of the truck 2.

Key Features

The Cummins 3523412 Split Ring Seal boasts several key features that enhance its performance. It is constructed from high-quality materials that offer durability and resistance to wear. The design of the seal allows for easy installation and removal, which is beneficial during maintenance procedures. Additionally, its split design enables it to accommodate minor misalignments, ensuring a consistent seal even under varying conditions 3.

Benefits

The use of the Cummins 3523412 Split Ring Seal offers several benefits. It provides improved sealing efficiency, which contributes to the overall performance of the truck’s engine or transmission. Its durable construction ensures a longer service life, reducing the frequency of replacements. Moreover, by preventing leaks and maintaining system pressures, it can lead to cost savings for fleet operators through reduced maintenance and repair costs.

Installation Process

Installing the Cummins 3523412 Split Ring Seal requires careful attention to ensure proper function. The process involves cleaning the sealing surfaces to remove any debris or old seal remnants. The seal should then be placed in the designated groove, ensuring it is seated correctly. Tools such as seal installation tools may be recommended to ensure the seal is properly installed without damage.

Common Issues and Troubleshooting

Common issues with the Cummins 3523412 Split Ring Seal may include leaks due to improper installation or wear over time. Troubleshooting these issues involves inspecting the seal for signs of damage or misalignment. If leaks are detected, the seal may need to be replaced. Ensuring proper installation techniques and regular inspections can help mitigate these issues.

Maintenance Tips

Regular maintenance of the Cummins 3523412 Split Ring Seal is crucial for its longevity and optimal performance. This includes periodic inspections for signs of wear or damage. Cleaning the sealing surfaces during maintenance intervals can prevent debris from affecting the seal’s performance. Following manufacturer recommendations for inspection and replacement intervals will help ensure the seal continues to function effectively.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history in the diesel engine industry, Cummins has established a reputation for quality and reliability in the commercial truck sector. Their components, including the Cummins 3523412 Split Ring Seal, are designed with the expertise and innovation that Cummins is known for, ensuring they meet the demanding requirements of commercial applications.

Cummins Part 3523412: Split Ring Seal Compatibility

The Cummins part 3523412, a Split Ring Seal, is a component designed to ensure the integrity of various engine systems. This seal is engineered to fit seamlessly with a range of Cummins engines, providing a reliable barrier against leaks and contamination. Below is a detailed description of its compatibility across different engine models.

Cummins K-Series Engines

The Split Ring Seal is compatible with several K-Series engines, including:

- K19

- K38

- K50

These engines benefit from the seal’s ability to maintain pressure and prevent fluid leakage, ensuring optimal performance and longevity.

Cummins N-Series Engines

For the N-Series engines, the seal fits with:

- N14 MECHANICAL

This seal is crucial in maintaining the mechanical integrity of the N14 MECHANICAL engine, ensuring that it operates efficiently and reliably.

Cummins QSK Engines

The Split Ring Seal is also compatible with a variety of QSK engines, including:

- QSK19 CM2350 K105

- QSK19 CM2350 K114

- QSK19 CM2350 K144G

- QSK19 CM500

- QSK19 CM850 MCRS

- QSK19G

- QSK38 CM2150 MCRS

- QSK38 CM850 MCRS

- QSK45 CM500

- QSK50 CM2150 K107

- QSK50 CM2150 MCRS

- QSK50 CM2350 K108

- QSK60 CM500

- QSK60 CM850 MCRS

- QSK60G

- QSK78 CM500

- QSK95 CM2350 K111

These engines, known for their robust performance, rely on the seal to maintain pressure and prevent leaks, ensuring that they run smoothly and efficiently.

Cummins QST Engines

The Split Ring Seal also fits with the following QST engines:

- QST30 CM2350 T101

- QST30 CM552

These engines benefit from the seal’s ability to maintain pressure and prevent leaks, ensuring that they operate efficiently and reliably.

Cummins NH/NT Engines

Lastly, the seal is compatible with:

- NH/NT 855

This seal is essential for maintaining the mechanical integrity of the NH/NT 855 engine, ensuring that it operates efficiently and reliably.

By ensuring a proper fit and function, the Cummins part 3523412, a Split Ring Seal, plays a vital role in the performance and longevity of these engines.

Role of Part 3523412 Split Ring Seal in Engine Systems

The Split Ring Seal, identified as part 3523412, is integral to the efficient operation of various engine components. Its primary function is to ensure a secure seal between mating surfaces, preventing leaks and maintaining system integrity.

Turbocharger Systems

In turbochargers such as the 49 State 444, HX80, and EBM models, the Split Ring Seal is used to create a tight seal between the turbine housing and the compressor housing. This seal is vital for maintaining the pressure differential necessary for efficient turbo operation. Additionally, in the Turbo Repair HC5A kit and the Turbo T18A KV16 kit, the seal ensures that the turbocharger can withstand high-pressure environments without compromising performance.

Aftercooler and Heat Exchanger

For the Aftercooler and the Core Assembly Heat Exchanger82, the Split Ring Seal plays a significant role in sealing the connections between the heat exchanger components. This ensures that the cooling process is effective, maintaining optimal temperatures for the compressed air before it enters the engine.

Cylinder Head and Mounting

In the Cylinder Head and Cylinder Head Mounting, the Split Ring Seal is employed to seal the connections between the cylinder head and the engine block. This prevents any coolant or oil leaks, ensuring that the combustion process remains efficient and that the engine operates within safe temperature ranges.

Piston and Bearing Kits

Within the Engine Piston Kit, HC5A Bearing/Seal Kit, and Heat4B Bearing/Seal Kit, the Split Ring Seal is used to ensure that the piston rings seal effectively against the cylinder walls. This is essential for maintaining compression and preventing blow-by, which can lead to reduced engine efficiency and increased emissions.

Turbocharger Gasket and Overhaul Kits

In the Turbocharger Gasket Kit and Overhaul Kit, the Split Ring Seal is a key component for ensuring that all gasketed joints in the turbocharger assembly are leak-free. This is particularly important in high-stress environments where even minor leaks can lead to significant performance issues.

Injectors and Power Turbine Drive

For Injectors and the Power Turbine Drive, the Split Ring Seal ensures that fuel delivery and turbine operation are precise and leak-free. This is essential for maintaining engine performance and fuel efficiency.

On Board Spares and Short Blocks

In the On Board Spares kit and the Short Block 6Cart and 6CTA, the Split Ring Seal is used to ensure that all temporary or replacement components fit securely and function as intended. This is crucial for maintaining engine reliability during operations where quick changes or repairs may be necessary.

Turbo & Intercooler Set

In the Turbo & Intercooler Gset, the Split Ring Seal ensures that the intercooler connections are secure, allowing for effective cooling of the compressed air before it enters the engine. This contributes to better engine performance and longevity.

The Split Ring Seal, part 3523412, is a versatile component that enhances the functionality and reliability of various engine systems by providing essential sealing capabilities.

Conclusion

The Cummins 3523412 Split Ring Seal is a critical component in the maintenance and efficiency of commercial truck engines and transmissions. Its design and features ensure reliable sealing, preventing leaks and maintaining system pressures. Regular maintenance and proper installation are essential for maximizing the benefits of this part, contributing to the overall performance and longevity of the vehicle.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.