This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

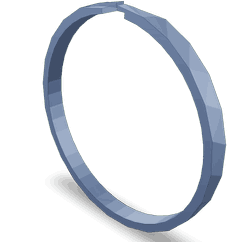

The Cummins 3521442 Split Ring Seal is a component designed to enhance the operational efficiency of commercial trucks. This seal plays a role in maintaining the integrity of various systems within the truck by providing a reliable barrier against leaks and contaminants. Its significance lies in ensuring that the truck operates smoothly and efficiently, contributing to overall performance and longevity.

Basic Concepts of Split Ring Seals

Split ring seals are mechanical components used to create a seal between two surfaces. They function by being compressed between a static and a dynamic part, thereby preventing the passage of fluids or gases. These seals are commonly applied in various mechanical systems to ensure that fluids remain contained within their designated pathways, thus maintaining system efficiency and preventing contamination 1.

Purpose of the Cummins 3521442 Split Ring Seal

The Cummins 3521442 Split Ring Seal serves a specific role in the operation of a truck. It is designed to fit into various components where sealing is required to maintain system integrity. This seal helps in preventing leaks, which can lead to system failures or reduced efficiency. By ensuring a tight seal, it contributes to the reliable operation of the truck’s systems.

Key Features

The Cummins 3521442 Split Ring Seal is characterized by several key features that enhance its performance. It is made from durable materials that can withstand high pressures and temperatures. The design of the seal allows for easy installation and removal, making it convenient for maintenance purposes. Additionally, its split design enables it to be flexible, adapting to the surfaces it seals against, which improves its effectiveness.

Benefits

The Cummins 3521442 Split Ring Seal offers several benefits. It provides improved sealing efficiency, which helps in maintaining the performance of the truck’s systems. Its durability ensures long-term reliability, reducing the need for frequent replacements. Moreover, its resistance to wear and tear contributes to its longevity, making it a cost-effective solution for sealing applications in commercial trucks.

Installation Process

Installing the Cummins 3521442 Split Ring Seal requires careful attention to detail to ensure optimal performance. The process involves cleaning the sealing surface to remove any contaminants that could affect the seal’s effectiveness. The seal is then placed into the designated groove, ensuring it is properly seated. Tools such as seal installation tools may be used to facilitate the process and ensure the seal is correctly positioned.

Common Issues and Troubleshooting

Common issues with the Cummins 3521442 Split Ring Seal may include improper seating, which can lead to leaks, or damage to the seal due to wear and tear. Troubleshooting these issues involves inspecting the seal for proper installation and condition. If leaks are detected, the seal may need to be reseated or replaced. Regular maintenance and inspection can help identify and address these issues before they lead to system failures.

Maintenance Tips

To ensure the long-term reliability and performance of the Cummins 3521442 Split Ring Seal, regular maintenance is recommended. This includes inspecting the seal for signs of wear or damage, cleaning the sealing surface to remove contaminants, and replacing the seal as needed. Adhering to these maintenance practices can help maintain the seal’s effectiveness and contribute to the overall efficiency of the truck’s systems.

Cummins Overview

Cummins Inc. is a renowned manufacturer with a strong reputation in the industry for producing high-quality automotive components. The company has a history of innovation and commitment to quality, which is reflected in its wide range of products designed to enhance the performance and reliability of commercial vehicles. Cummins’ dedication to excellence ensures that its components, including the 3521442 Split Ring Seal, meet the demanding requirements of the automotive industry.

Cummins Split Ring Seal 3521442 Compatibility

The Cummins Split Ring Seal part number 3521442 is a versatile component designed to fit a variety of Cummins engines. This seal is crucial for maintaining the integrity of the engine’s lubrication system by preventing leaks and ensuring that oil remains within the designated pathways. Below is a detailed description of the engines with which this seal is compatible:

K-Series Engines

- K19

- K38

- K50

The K-Series engines are known for their robust design and reliability, often used in heavy-duty applications. The Split Ring Seal 3521442 is compatible with these engines, ensuring that they maintain optimal performance by preventing oil leaks.

QSK-Series Engines

- QSK19 CM2350 K105

- QSK19 CM2350 K114

- QSK19 CM2350 K144G

- QSK19 CM500

- QSK19 CM850 MCRS

- QSK19G

- QSK38 CM2150 MCRS

- QSK38 CM850 MCRS

- QSK45 CM500

The QSK-Series engines are high-performance engines designed for demanding applications. The Split Ring Seal 3521442 is engineered to fit these engines, providing a reliable seal that helps maintain the engine’s efficiency and longevity.

KTA-Series Engines

- KTA19GC

- KTA19GC CM558

- KTA38GC CM558

The KTA-Series engines are known for their power and reliability in various industrial applications. The Split Ring Seal 3521442 is compatible with these engines, ensuring that they operate smoothly by preventing oil leaks.

N14 Engines

- N14 CELECT

- N14 CELECT PLUS

- N14 MECHANICAL

The N14 engines are a staple in the heavy-duty market, offering a balance of power and efficiency. The Split Ring Seal 3521442 fits these engines, providing a critical seal that helps maintain their performance.

Other Cummins Engines

- 6B5.9

- GTA38 G CMEICS G116C

- ISX CM570

- ISX CM870

- ISX CM871

- ISX15 CM2250 SN

- NH/NT 855

These engines, while diverse in their applications, all benefit from the Split Ring Seal 3521442. This seal is designed to fit these engines, ensuring that they operate efficiently by preventing oil leaks and maintaining proper lubrication.

By ensuring compatibility with a wide range of Cummins engines, the Split Ring Seal 3521442 plays a crucial role in maintaining engine performance and reliability.

Role of Part 3521442 Split Ring Seal in Engine Systems

The Part 3521442 Split Ring Seal is an essential component in various engine systems, ensuring optimal performance and reliability. Its application spans across multiple critical areas within the engine, contributing to the efficient operation of several key components.

Turbocharger Systems

In turbocharger assemblies, the Split Ring Seal is utilized to maintain the integrity of the sealing surfaces. It is particularly important in the EBM-Turbocharger and Heat3B Turbocharger, where it prevents leaks and ensures that the compressed air is effectively delivered to the engine. This seal is also vital in the Heat80 Turbocharger, where it helps in maintaining the high-pressure environment necessary for efficient turbo operation.

Heat Exchanger Assemblies

The Split Ring Seal plays a significant role in the Core Assembly Heat Exchanger systems, such as the Core Assembly Heat Exchanger60 and Core Assembly Heat Exchanger83. It ensures that the transfer of heat between the fluids is efficient and that there are no leaks, which could compromise the system’s performance. In the Core Heat Exchanger60 Assembly and Core Heat Exchanger60W Assembly, this seal is crucial for maintaining the structural integrity and operational efficiency.

Camshaft and Related Components

In the Camshaft Right Bank and Cam Follower Shaft Support, the Split Ring Seal is used to ensure that the moving parts operate smoothly without any unwanted leaks or friction. This is essential for the longevity and performance of the camshaft system.

Oil Manifold and Short Block

Within the Oil Manifold and Short Block 6CTA, the Split Ring Seal helps in maintaining the pressure and flow of oil to various engine components. This ensures that all moving parts are adequately lubricated, reducing wear and tear and enhancing the engine’s overall efficiency.

Injector and On Board Spares

The seal is also employed in Injector systems to ensure that fuel delivery is precise and leak-free. In On Board Spares kits, the Split Ring Seal is included to provide a reliable solution for maintaining the integrity of various engine components during repairs or maintenance.

Turbocharger Repair and Parts Kits

In Turbocharger Repair Heat3B/Heat60 Kit and Turbocharger Parts Kit, the Split Ring Seal is a fundamental component. It ensures that during repairs or replacements, the sealing surfaces are maintained, thereby preserving the efficiency and performance of the turbocharger system.

Aftermarket and Incomplete Turbocharger

For Aftermarket Turbocharger and Incomplete Turbocharger systems, the Split Ring Seal is essential for ensuring that the aftermarket components integrate seamlessly with the existing engine system, maintaining performance standards and reliability.

Conclusion

In summary, the Part 3521442 Split Ring Seal is a versatile and vital component across various engine systems, contributing to the efficiency, reliability, and performance of the engine. Its role in preventing leaks and maintaining system integrity is crucial for the smooth operation of commercial trucks. Regular maintenance and proper installation are key to ensuring the long-term effectiveness of this Cummins part.

-

Limpert, Rudolf. Brake Design and Safety, Third Edition. SAE International, 2011.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.