3393587

O-Ring Seal

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3393587 O-Ring Seal is a component designed to ensure the integrity of fluid systems within heavy-duty trucks. Its role is to prevent leaks and maintain system pressure, contributing to the overall efficiency and reliability of truck operations. Understanding its function and significance is vital for maintaining the performance and longevity of heavy-duty vehicles.

Basic Concepts of O-Ring Seals

An O-Ring Seal is a type of gasket consisting of a toroidal piece of elastomer with a round cross-section. It creates a seal by being compressed in a groove, forming a barrier that prevents the passage of fluids or gases. Materials commonly used for O-Rings include nitrile rubber, silicone, and fluorocarbon, chosen for their resistance to various chemicals and temperatures. The seal is achieved through the O-Ring’s ability to deform under compression, filling the space between mating surfaces and blocking fluid paths 1.

Role of the 3393587 O-Ring Seal in Truck Operation

The Cummins 3393587 O-Ring Seal is specifically designed to play a role in the fluid systems of heavy-duty trucks. It is associated with components such as fuel injectors, where it helps maintain the integrity of the fuel system by preventing leaks. This ensures that the fuel delivery system operates efficiently, contributing to the truck’s performance and fuel economy 2.

Key Features of the 3393587 O-Ring Seal

The Cummins 3393587 O-Ring Seal is characterized by its precise design and material properties. It is made from high-quality elastomers that offer excellent resistance to the fuels and temperatures encountered in heavy-duty truck applications. Its design ensures a snug fit in the designated grooves, providing a reliable seal under various operating conditions 3.

Benefits of Using the 3393587 O-Ring Seal

Utilizing the Cummins 3393587 O-Ring Seal offers several advantages. It contributes to improved system efficiency by ensuring that fluids are contained within their intended paths. This seal enhances the longevity of the associated components by protecting them from contamination and wear. Additionally, it increases the reliability of the truck’s fluid systems, reducing the likelihood of unexpected failures 4.

Installation Considerations

Proper installation of the Cummins 3393587 O-Ring Seal is crucial for its effectiveness. Guidelines recommend using the appropriate tools to avoid damaging the O-Ring during installation. It should be lubricated with a compatible fluid to facilitate placement and ensure it seats correctly in the groove. Following Cummins’ recommended procedures ensures the seal functions as intended and maintains its integrity over time 5.

Troubleshooting Common Issues

Common issues with O-Ring Seals include leaks, which can arise from improper installation, degradation of the elastomer, or incompatible fluids. Diagnosing problems with the 3393587 O-Ring Seal involves inspecting the seal for signs of wear or damage and ensuring it is correctly installed. Solutions may include replacing the O-Ring or addressing underlying issues such as fluid contamination 6.

Maintenance Tips

To prolong the life of the Cummins 3393587 O-Ring Seal, regular maintenance is recommended. This includes inspecting the seal during routine service intervals for signs of wear or damage. Cleaning the seal and its groove with a compatible solvent can remove contaminants that may accelerate degradation. Replacement should be considered if the seal shows signs of failure or if the associated component is being serviced 7.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the automotive and heavy-duty truck industry. Its product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of commercial vehicles.

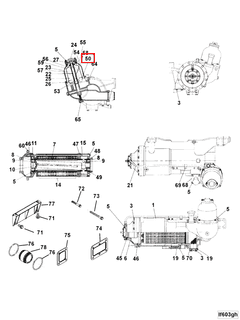

Cummins Engine Part 3393587 O-Ring Seal Application

The Cummins part 3393587 O-Ring Seal is a critical component used in various Cummins engine models. This O-Ring Seal is designed to provide a reliable seal in high-pressure environments, ensuring that the engine operates efficiently and safely.

Application in Cummins Engines

-

QSK45 CM500, QSK60 CM500, QSK78 CM500

The O-Ring Seal part 3393587 is utilized in these engines to maintain the integrity of the sealing surfaces, preventing leaks and ensuring optimal performance. These engines are known for their robust construction and are often used in demanding applications such as power generation, marine, and industrial settings.

-

QSK60 CM850 MCRS, QSK60G

In the QSK60 CM850 MCRS and QSK60G engines, the O-Ring Seal part 3393587 plays a crucial role in sealing various components, ensuring that there is no loss of pressure or contamination. These engines are designed for heavy-duty applications and require high-quality sealing solutions to maintain their performance and reliability.

The O-Ring Seal part 3393587 is integral to the operation of these Cummins engines, providing a dependable seal that is essential for their performance and longevity.

Role of Part 3393587 O-Ring Seal in Engine Systems

The 3393587 O-Ring Seal is instrumental in maintaining the integrity and efficiency of various engine systems. In the context of a Full Flow Oil Filter, this O-Ring Seal ensures a tight and secure fit between the filter and the engine block, preventing oil leaks and maintaining consistent oil pressure.

When integrated into a Lubricating Oil Filter Kit, the O-Ring Seal plays a significant role in sealing the connections between the filter elements and the housing, ensuring that the lubrication system operates without interruptions.

In a Centrifuge Lubricating Oil Filter, the O-Ring Seal is positioned to seal the rotating components from the stationary parts, which is essential for the efficient separation of contaminants from the oil.

For the Lubricating Oil Filter Head, the O-Ring Seal is critical in creating a leak-proof connection between the filter head and the engine, ensuring that the filtration process is effective and that clean oil is consistently delivered to the engine components.

In an Oil Cooler Repair Kit, the O-Ring Seal is used to seal the connections within the cooler, ensuring that the oil cooling process is efficient and that there are no leaks in the system. This helps in maintaining the optimal temperature of the lubricating oil, which is vital for engine performance and longevity.

Conclusion

The Cummins 3393587 O-Ring Seal is a vital component in the maintenance and operation of heavy-duty truck engines. Its precise design and material properties ensure reliable sealing in various engine systems, contributing to the efficiency, reliability, and longevity of the engine. Proper installation, regular maintenance, and timely replacement are essential practices to maximize the benefits of this Cummins part.

-

Lakshminarayanan, P A, and Yogesh V Aghav. Modelling Diesel Combustion. Springer Science, 2010.

↩ -

Hilgers, Michael. Fuel Consumption and Consumption Optimization, Second Edition. Springer Nature, 2023.

↩ -

Gilles, Tim. Automotive Service: Inspection, Maintenance, Repair: 2nd Edition. Cengage Learning, 2020.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 5612926, QSK38 CM2350 K145G.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 5612926, QSK38 CM2350 K145G.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 5612926, QSK38 CM2350 K145G.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 5612926, QSK38 CM2350 K145G.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.