This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

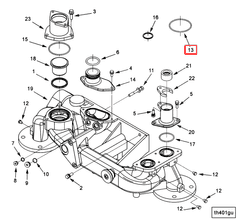

The 3348885 O-Ring Seal, manufactured by Cummins, is a component designed for use in commercial truck applications. Cummins, a well-established name in the automotive industry, produces this O-Ring Seal to meet the demanding requirements of heavy-duty truck operations. This seal plays a role in ensuring the integrity of various systems within commercial trucks, contributing to their overall performance and reliability 1.

Basic Concepts of O-Ring Seals

An O-Ring Seal is a type of gasket with a circular cross-section, designed to create a seal between two or more parts. In mechanical systems, O-Ring Seals are used to prevent the leakage of fluids and gases, ensuring the system operates efficiently. They work by being compressed between flanges or within a groove, creating a barrier that blocks the passage of substances 2.

Purpose of the 3348885 O-Ring Seal in Truck Operations

This Cummins part is utilized in commercial trucks to maintain the sealing integrity of various components and systems. It is commonly applied in areas where fluid or gas containment is necessary, such as in the engine, transmission, and hydraulic systems. By providing a reliable seal, this O-Ring contributes to the efficient operation of these systems, helping to prevent leaks that could lead to performance issues or damage 3.

Key Features of the 3348885 O-Ring Seal

The 3348885 O-Ring Seal is engineered with specific design and material characteristics to enhance its effectiveness and durability in heavy-duty truck environments. It is made from materials that offer resistance to a wide range of temperatures, chemicals, and physical stresses. Its design ensures a snug fit in the designated grooves or flanges, providing a consistent and reliable seal under various operating conditions 4.

Benefits of Using the 3348885 O-Ring Seal

The use of the 3348885 O-Ring Seal offers several advantages in commercial truck applications. It provides improved sealing performance, which helps in maintaining system efficiency and preventing leaks. Its durability ensures a longer service life, reducing the frequency of replacements. Additionally, its resistance to environmental factors such as temperature extremes and chemical exposure contributes to its reliability in demanding truck operations 5.

Installation Considerations

Proper installation of the 3348885 O-Ring Seal is key to ensuring its optimal performance and longevity. It is important to follow guidelines that include cleaning the sealing area, inspecting the O-Ring for any defects before installation, and ensuring it is properly seated in its groove without twists or kinks. Careful handling and installation help in achieving the desired sealing effectiveness 6.

Troubleshooting Common Issues

In truck applications, O-Ring Seals may encounter issues such as leaks or failure due to wear, improper installation, or exposure to incompatible substances. Troubleshooting these problems involves inspecting the seal and its seating area for damage, ensuring correct installation, and verifying compatibility with the system’s fluids and operating conditions. Addressing these issues promptly helps in maintaining the seal’s effectiveness and the system’s performance 7.

Maintenance Tips

Regular maintenance of the 3348885 O-Ring Seal is recommended to prolong its service life and maintain its sealing efficiency. This includes periodic inspection for signs of wear or damage, cleaning the sealing area to remove contaminants, and replacing the seal as needed based on the manufacturer’s guidelines or upon signs of degradation. Proper maintenance ensures the continued reliability of the seal and the systems it protects 8.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. Its product range includes engines, powertrain components, and aftermarket parts, all designed to meet the rigorous demands of heavy-duty applications. Cummins’ commitment to excellence and customer satisfaction has made it a trusted name in the industry 9.

Cummins O-Ring Seal Part 3348885 in Engine Applications

The Cummins O-Ring Seal part number 3348885 is a critical component in various engine systems, ensuring the integrity and efficiency of the engine’s operations. This seal is designed to prevent leaks and maintain pressure within the engine, which is essential for optimal performance and longevity.

Application in K19 Engines

In the K19 engine series, the O-Ring Seal part 3348885 plays a pivotal role in sealing critical junctures where different components interface. This seal is typically used in areas where there is a need to prevent fluid or gas from escaping, ensuring that the engine operates under the right conditions. Its placement is crucial, often found in high-pressure zones where the seal must withstand both mechanical and thermal stresses.

Grouping of Engines

The O-Ring Seal part 3348885 is not limited to the K19 engine series but is also utilized in other Cummins engine groups where similar sealing requirements are present. This part is designed to be versatile, fitting seamlessly into various engine configurations while maintaining its primary function of providing a reliable seal.

Importance of the Seal

The importance of the O-Ring Seal part 3348885 cannot be overstated. Its role in preventing leaks and maintaining system integrity is vital for the overall health of the engine. By ensuring that the seal is properly installed and maintained, engine operators can avoid potential downtime and costly repairs, ensuring that the engine continues to perform at its best.

Role of Part 3348885 O-Ring Seal in Engine Systems

The part 3348885 O-Ring Seal is instrumental in ensuring the integrity and efficiency of various engine systems. In the accessory drive system, it maintains a secure seal around the components, preventing leaks and ensuring smooth operation of driven accessories.

Within the drive system, the O-Ring Seal plays a key role in sealing connections and joints, which is essential for the reliable transfer of power from the engine to other components.

In the fuel pump system, the O-Ring Seal is used to create a tight seal around the pump housing and connections. This prevents fuel leaks and maintains the necessary pressure within the fuel lines, ensuring efficient fuel delivery to the engine.

The housing components, such as those found in the thermostat and inlet manifold, rely on the O-Ring Seal to prevent coolant and air leaks. This ensures that the engine operates within the optimal temperature range and that the air-fuel mixture is correctly metered for combustion.

In the thermostat housing, the O-Ring Seal is vital for maintaining the seal around the thermostat, which regulates the flow of coolant based on engine temperature. This helps in achieving the desired engine operating temperature more quickly and maintaining it consistently.

Lastly, in the inlet manifold, the O-Ring Seal ensures that the air entering the engine is metered accurately without any leaks, which is essential for optimal engine performance and fuel efficiency.

Conclusion

The 3348885 O-Ring Seal by Cummins is a vital component in the maintenance and efficiency of commercial truck engines. Its design and material properties ensure durability and reliability under demanding conditions, contributing to the overall performance and longevity of the engine systems it serves. Proper installation, maintenance, and timely replacement are key to maximizing the benefits of this Cummins part, ensuring that commercial trucks operate efficiently and reliably.

-

Rajamani, R. (2005). Vehicle Dynamics and Control. Springer.

↩ -

Robert Bosch GmbH. (2007). Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive 5th Edition. Springer Vieweg.

↩ -

Hick, H., Kupper, K., & Sorger, H. (2021). Systems Engineering for Automotive Powertrain Development. Springer.

↩ -

General Information, Bulletin Number 4021427, Owners Manual.

↩ -

Rajamani, R. (2005). Vehicle Dynamics and Control. Springer.

↩ -

Robert Bosch GmbH. (2007). Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive 5th Edition. Springer Vieweg.

↩ -

Hick, H., Kupper, K., & Sorger, H. (2021). Systems Engineering for Automotive Powertrain Development. Springer.

↩ -

General Information, Bulletin Number 4021427, Owners Manual.

↩ -

Hick, H., Kupper, K., & Sorger, H. (2021). Systems Engineering for Automotive Powertrain Development. Springer.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.