Introduction

The Cummins 206449 O-Ring Seal is a component designed to ensure the integrity of fluid systems in heavy-duty trucks. Its role is to prevent leaks and maintain system pressure, contributing to the overall efficiency and reliability of truck operations. Understanding the function and significance of this seal is vital for maintaining the performance and longevity of heavy-duty vehicles.

Basic Concepts of O-Ring Seals

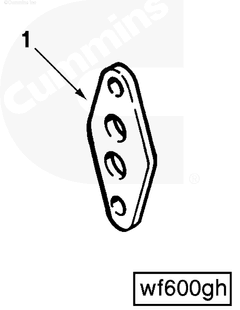

An O-Ring Seal is a type of gasket with a circular cross-section, designed to create a seal between two or more parts. It operates by being compressed within a groove, forming a barrier that prevents the escape of fluids or gases. O-Rings are widely used in mechanical systems due to their simplicity, effectiveness, and versatility in various applications 1.

Purpose of the 206449 O-Ring Seal in Truck Operation

The 206449 O-Ring Seal plays a specific role in the operation of heavy-duty trucks by ensuring the sealing of fluid systems. It is commonly applied in areas where fluid dynamics are critical, such as in the engine, transmission, and hydraulic systems. By maintaining a tight seal, it supports the efficient operation of these systems, preventing fluid loss and ensuring consistent performance under demanding conditions 2.

Key Features of the 206449 O-Ring Seal

The primary characteristics of the 206449 O-Ring Seal include its material composition, typically a durable elastomer, and its precise dimensions tailored to fit specific applications. The design features of this seal enhance its performance and durability, allowing it to withstand high pressures and temperatures commonly encountered in heavy-duty truck environments 3.

Benefits of Using the 206449 O-Ring Seal

Utilizing the 206449 O-Ring Seal offers several advantages, including improved system efficiency through effective sealing, enhanced longevity due to its durable construction, and increased reliability in harsh operating conditions. These benefits contribute to the overall performance and maintenance of heavy-duty trucks, reducing the likelihood of system failures and the need for frequent repairs.

Installation Considerations

Proper installation of the 206449 O-Ring Seal is crucial for ensuring optimal performance and longevity. Guidelines for installation include careful handling to avoid damage, ensuring the groove is clean and free of debris, and using the correct lubrication to facilitate seating. Following these best practices helps maintain the integrity of the seal and the systems it protects.

Troubleshooting Common Issues

Typical problems associated with O-Ring Seals, such as leaks or failures, can often be traced to installation errors, material degradation, or mechanical stress. Diagnosing these issues involves inspecting the seal for signs of wear or damage, checking the condition of the groove, and assessing the system for any abnormalities that may affect seal performance. Addressing these issues promptly can prevent more significant problems and maintain system efficiency.

Maintenance Tips

Regular inspection and maintenance of the 206449 O-Ring Seal are recommended to prolong its service life and maintain system integrity. This includes checking for signs of wear or damage, ensuring the groove remains clean, and replacing the seal as necessary. Adhering to these maintenance practices helps ensure the continued reliability and performance of heavy-duty truck systems.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins serves customers in approximately 190 countries and territories, offering a wide range of products for automotive, heavy-duty, and industrial applications. The company’s reputation in the automotive and heavy-duty truck industry is built on its commitment to excellence, reliability, and customer satisfaction.

Compatibility of O-Ring Seal Part 206449 with Cummins Engines

The O-Ring Seal part 206449, manufactured by Cummins, is designed to fit a variety of Cummins engines. This part is crucial for maintaining the integrity of fluid systems within these engines, ensuring that there are no leaks or fluid loss, which can lead to performance issues and potential engine damage.

GTA38 G CMEICS G116C

The O-Ring Seal part 206449 is compatible with the GTA38 G CMEICS G116C engine, providing a secure seal in critical areas where fluid containment is essential.

K38, K50, KTA38GC CM558, QSK38 CM2150 MCRS, QSK38 CM850 MCRS

This seal is also suitable for the K38, K50, and KTA38GC CM558 engines. Additionally, it fits the QSK38 CM2150 MCRS and QSK38 CM850 MCRS engines, ensuring that these models maintain optimal fluid pressure and system efficiency.

QSK50 CM2150 K107, QSK50 CM2150 MCRS, QSK50 CM2350 K108

The O-Ring Seal part 206449 is designed to work with the QSK50 CM2150 K107, QSK50 CM2150 MCRS, and QSK50 CM2350 K108 engines. These engines benefit from the seal’s ability to prevent leaks and maintain the necessary fluid levels for smooth operation.

QST30 CM2350 T101, QST30 CM552

Lastly, the seal is compatible with the QST30 CM2350 T101 and QST30 CM552 engines. It ensures that these engines operate efficiently by providing a reliable seal in areas where fluid containment is critical.

Role of Part 206449 O-Ring Seal in Engine Systems

The O-Ring Seal, identified by part number 206449, is integral to the reliable operation of various engine components. Its primary function is to provide a secure seal, preventing fluid leaks and ensuring system integrity.

Accessories Mounting

In accessories mounting applications, the O-Ring Seal is used to secure components such as pumps, sensors, and other auxiliary devices to the engine block or manifold. This seal ensures that any fluid pathways remain intact, preventing leaks that could lead to system failure or contamination.

Aftercooler

Within the aftercooler system, the O-Ring Seal is employed at connection points between the cooler body and its associated piping. This ensures that the compressed air is effectively cooled without any loss of pressure or introduction of contaminants.

Corrosion Resistor and Corrosion Resistor Assembly

For corrosion resistors and their assemblies, the O-Ring Seal plays a vital role in maintaining the integrity of the sealed environment. This is particularly important in marine or industrial applications where exposure to corrosive elements is high. The seal prevents moisture and corrosive agents from compromising the resistor’s performance.

Corrosion Resistor Head

At the corrosion resistor head, the O-Ring Seal is critical for maintaining a tight seal around the head’s connection points. This prevents any ingress of corrosive substances, ensuring the longevity and effectiveness of the resistor.

Engine Kit

In engine kits, the O-Ring Seal is often included to ensure all fluid pathways within the engine are properly sealed. This is essential for maintaining oil pressure, coolant flow, and fuel system integrity, all of which are fundamental to engine performance and durability.

Lower Engine Gasket Set and Overhaul Gasket Set

Both the lower engine gasket set and the overhaul gasket set incorporate O-Ring Seals at various points to ensure comprehensive sealing across the engine block, crankshaft, and other critical areas. This is essential for preventing oil leaks, maintaining compression, and ensuring the engine operates within specified parameters.

Package and Product Installation

During the installation of engine packages or individual products, O-Ring Seals are used to ensure that all connections are leak-free. This is particularly important in high-pressure systems where even a small leak can lead to significant performance issues.

Resistor, Corrosion

For corrosion resistors, the O-Ring Seal is used to create a barrier against environmental elements. This ensures that the resistor can perform its function without degradation over time, maintaining the overall efficiency of the engine system.

System, Auxiliary Cooling

In auxiliary cooling systems, O-Ring Seals are utilized at connection points to ensure that coolant flows smoothly without any leaks. This is essential for maintaining optimal engine temperature and preventing overheating.

Thermostat Housing

The thermostat housing often incorporates O-Ring Seals to ensure a tight fit around the thermostat and its connection points. This seal is vital for maintaining consistent coolant flow and temperature regulation within the engine.

Conclusion

Overall, the O-Ring Seal (part 206449) is a fundamental component in ensuring the integrity and efficiency of various engine systems, playing a key role in preventing leaks and maintaining system performance.

-

Goodnight, N., & VanGelder, K. (2019). Automotive Braking Systems CDX Master Automotive Technician Series. Jones Bartlett Learning.

↩ -

Hu, H., Baseley, S. J., & Song, X. (2021). Advanced Hybrid Powertrains for Commercial Vehicles Second Edition. SAE International.

↩ -

Kasab, J., & Strzelec, A. (2020). Automotive Emissions Regulations and Exhaust Aftertreatment Systems. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.