This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 199789 O-Ring Seal, manufactured by Cummins, is a component designed for use in commercial trucks. Cummins, a well-established manufacturer in the industry, produces a range of parts aimed at enhancing the performance and reliability of heavy-duty vehicles. Seals, such as the 199789 O-Ring Seal, play a significant role in maintaining the integrity of various systems within these trucks by preventing leaks and ensuring proper function 1.

Basic Concepts of O-Ring Seals

An O-Ring Seal is a type of gasket that forms a seal by being compressed within a groove. It is typically made from elastomers, which are materials known for their flexibility and resilience. The principle behind an O-Ring Seal’s function is its ability to deform under compression, creating a tight seal that prevents the passage of fluids or gases. This makes O-Ring Seals suitable for a wide range of applications where sealing is required 2.

Role of the 199789 O-Ring Seal in Truck Operations

In commercial trucks, the 199789 O-Ring Seal is utilized in systems where fluid or gas containment is necessary. It is commonly associated with components such as fuel injectors, where it helps maintain the integrity of the fuel system by preventing leaks. The seal ensures that the fuel delivery system operates efficiently, contributing to the overall performance of the truck 3.

Key Features of the 199789 O-Ring Seal

This Cummins part is characterized by its specific design and material properties. It is crafted from high-quality elastomers that offer excellent resistance to the chemicals and temperatures encountered in truck environments. The seal’s design ensures a snug fit within its designated groove, enhancing its ability to create and maintain a reliable seal. These features contribute to the seal’s performance and durability in demanding conditions.

Benefits of Using the 199789 O-Ring Seal

Utilizing the 199789 O-Ring Seal in commercial trucks offers several advantages. It contributes to improved system efficiency by ensuring that fluids or gases are contained within their intended pathways. The seal’s durability and resistance to wear also enhance the longevity and reliability of the systems it is part of, reducing the need for frequent replacements and maintenance.

Installation Considerations

Proper installation of the 199789 O-Ring Seal is crucial for its effective function. It should be installed in a clean, undamaged groove to ensure a proper fit. Using the correct tools and techniques during installation helps prevent damage to the seal and ensures that it forms a reliable seal. Following manufacturer guidelines for installation is recommended to achieve the best results.

Troubleshooting Common Issues

Common problems associated with O-Ring Seals include leaks or failure due to wear, exposure to incompatible fluids, or incorrect installation. Troubleshooting these issues involves inspecting the seal for signs of damage or wear, checking for proper installation, and ensuring compatibility with the system’s fluids and operating conditions. Addressing these issues promptly helps maintain system integrity and performance.

Maintenance Tips

Regular maintenance of the 199789 O-Ring Seal involves periodic inspection for signs of wear or damage. It is important to follow recommended inspection intervals and replace the seal if any signs of degradation are observed. Keeping the seal and its groove clean and free from contaminants also contributes to its longevity and effectiveness.

Cummins: A Brief Overview

Cummins is a reputable manufacturer with a long history in the industry, known for producing a wide range of products for commercial trucks. Their commitment to quality and innovation has established them as a trusted name in the field. Cummins’ products, including the 199789 O-Ring Seal, are designed to meet the demanding requirements of heavy-duty truck applications, ensuring reliability and performance.

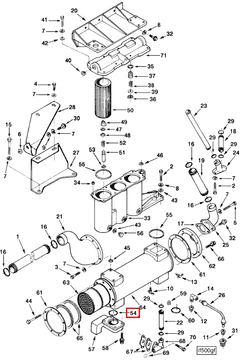

Cummins O-Ring Seal Part 199789 in V28 Engines

The Cummins O-Ring Seal part number 199789 is a critical component in the V28 engine series. This seal is designed to provide a reliable barrier against leaks, ensuring that the engine operates efficiently and safely. The O-Ring Seal is typically used in areas where a rotating shaft passes through a housing, preventing the escape of fluids such as oil, coolant, or air.

In the V28 engine, this seal is strategically placed in high-stress areas to maintain the integrity of the engine’s internal systems. Its placement is crucial for maintaining the pressure and preventing contamination, which can lead to engine failure if not properly sealed. The durability and precision of the O-Ring Seal are essential for the longevity and performance of the V28 engine.

The seal’s material is chosen for its ability to withstand high temperatures and pressures, ensuring that it performs reliably under the demanding conditions of engine operation. This part is integral to the engine’s design, providing a seamless connection between moving parts and stationary components, thereby contributing to the overall efficiency and reliability of the V28 engine.

Component Usage of the 199789 O-Ring Seal

The 199789 O-Ring Seal is an essential component in various engine systems, ensuring the integrity and efficiency of these systems. Here’s how it integrates with the provided components:

Cooler Systems

In cooler systems, the O-Ring Seal is used to create a tight seal between the cooler and its housing. This prevents any leakage of coolant or oil, maintaining the efficiency of the cooling process. It is particularly important in systems where temperature regulation is vital for engine performance.

Engine Oil Systems

Within engine oil systems, the O-Ring Seal is employed to seal connections between the engine oil filter and the engine block. This ensures that oil flows smoothly through the system without any leaks, which is essential for lubricating moving parts and reducing friction.

Lubricating Filter Systems

For lubricating filters, the O-Ring Seal is used to secure the filter housing to the engine or machinery. This seal is critical in preventing contaminants from entering the lubrication system, thereby prolonging the life of the engine components and ensuring optimal performance.

Filter and Cooler Assemblies

In combined filter and cooler assemblies, such as the Lube Oil Filter-Cooler, the O-Ring Seal plays a dual role. It ensures that both the filtration and cooling processes occur without any cross-contamination or leakage, which is essential for maintaining the quality of the lubricating oil.

Lubricating Oil Systems

In lubricating oil systems, the O-Ring Seal is utilized at various connection points to maintain the integrity of the oil flow. This includes seals at the lubricating oil filter, lubricating oil cooler, and other components within the system. Proper sealing is necessary to prevent oil degradation and ensure consistent lubrication.

Overhaul Gasket Sets

When it comes to overhaul gasket sets, the O-Ring Seal is often included to provide a reliable seal during engine maintenance or rebuilds. This ensures that all fluid systems within the engine remain leak-free, contributing to the overall reliability and performance of the engine post-overhaul.

PDC Systems

In Powertrain Control Modules (PDC) that interface with lubrication systems, the O-Ring Seal ensures that electrical connections and fluid pathways remain isolated. This is important for maintaining the accuracy of sensor readings and the overall functionality of the powertrain system.

Conclusion

By understanding the role of the 199789 O-Ring Seal in these various components, engineers and mechanics can better appreciate its importance in maintaining the efficiency and reliability of engine systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.