4298993

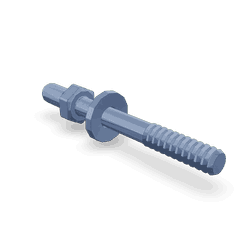

Studded Captive Washer Screw

Cummins®

AVAILABLE

7 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Studded Captive Washer Screw, identified by Part #4298993, is a specialized fastener produced by Cummins, a leading manufacturer in the automotive and heavy-duty truck industries. This component is integral to the maintenance and operation of heavy-duty trucks, ensuring secure fastening and structural integrity in various applications.

Basic Concepts

A Studded Captive Washer Screw is a type of fastener that includes a threaded stud, a captive washer, and a screw head. The threaded stud allows for secure attachment to components, while the captive washer provides additional support and stability. This design ensures that the washer remains in place during installation and operation, enhancing the overall fastening security 1.

Purpose and Role

The Studded Captive Washer Screw plays a significant role in the operation of heavy-duty trucks by securing critical components and maintaining structural integrity. It is commonly used in applications where vibration and movement are prevalent, such as in engine mounts, exhaust systems, and chassis components. The screw’s design helps to distribute load and prevent loosening, which is vital for the safe and efficient operation of the vehicle 2.

Key Features

The Studded Captive Washer Screw is characterized by several key features that enhance its performance and durability. Its design includes a robust threaded stud made from high-strength materials, ensuring resistance to wear and corrosion. The captive washer is typically made from a durable polymer or metal, providing additional support and stability. The screw head is designed for easy installation and removal, often featuring a hexagonal or Torx pattern for secure tool engagement 3.

Benefits

Using a Studded Captive Washer Screw offers several advantages. The captive washer design ensures that the washer remains in place, reducing the risk of loss during installation. This feature enhances fastening security and simplifies the installation process. Additionally, the screw’s resistance to vibration and corrosion makes it suitable for use in harsh operating conditions, contributing to the longevity and reliability of the fastening application.

Installation Process

Proper installation of the Studded Captive Washer Screw involves several steps to ensure optimal performance. Begin by selecting the appropriate size and type of screw for the application. Clean the installation surface to remove any debris or contaminants that could affect the screw’s grip. Insert the threaded stud into the designated hole and use a compatible tool to tighten the screw head securely. Ensure that the captive washer is properly seated and that the screw is tightened to the manufacturer’s specified torque settings to avoid over-tightening or under-tightening.

Troubleshooting and Maintenance

Common issues with the Studded Captive Washer Screw include loosening due to vibration and corrosion from exposure to harsh environments. Regular inspection and maintenance can help identify these issues early. If loosening is detected, re-tighten the screw to the specified torque settings. In cases of corrosion, clean the affected area and consider applying a corrosion-resistant coating to prevent further degradation. Replacing worn or damaged screws promptly can help maintain the integrity of the fastening application.

Manufacturer Overview - Cummins

Cummins is a renowned manufacturer with a rich history in the automotive and trucking industries. The company offers a wide range of products, including engines, powertrains, and aftermarket parts, known for their quality and reliability. Cummins’ reputation is built on a commitment to innovation, customer satisfaction, and excellence in manufacturing, making it a trusted name in the industry.

Studded Captive Washer Screw (Part 4298993) in Cummins Engines

The Studded Captive Washer Screw, identified by the part number 4298993, is a critical component in the assembly and maintenance of various Cummins engines. This part is designed to secure different components within the engine, ensuring stability and integrity during operation.

Application in Cummins Engines

ISX CM570 and QSX15 CM2350 X105

The Studded Captive Washer Screw is utilized in the ISX CM570 and QSX15 CM2350 X105 engines, both of which are part of Cummins’ extensive lineup of commercial and industrial engines. These engines are known for their robust performance and reliability, often used in heavy-duty applications such as trucks, construction equipment, and power generation.

In these engines, the Studded Captive Washer Screw plays a pivotal role in securing various parts, including but not limited to, engine mounts, brackets, and other critical assemblies. Its design ensures that these components remain firmly in place, even under the strenuous conditions these engines typically encounter.

Functionality and Importance

The studded design of the washer screw provides enhanced grip and resistance to loosening, which is essential in maintaining the structural integrity of the engine. This is particularly important in high-vibration and high-stress environments where components are subjected to constant movement and force.

By ensuring that parts remain tightly secured, the Studded Captive Washer Screw contributes to the overall reliability and longevity of the engine. It is a testament to Cummins’ commitment to quality and durability, ensuring that their engines can perform consistently under demanding conditions.

Compatibility and Installation

When installing the Studded Captive Washer Screw in Cummins engines, it is crucial to follow the manufacturer’s guidelines to ensure proper fit and function. This includes using the correct torque specifications and ensuring that the screw is compatible with the specific engine model and application.

The screw’s design allows for easy installation and removal, facilitating maintenance and repair processes. This ease of use is a key factor in the widespread adoption of this component across various Cummins engine models.

By understanding the role and importance of the Studded Captive Washer Screw in Cummins engines, technicians and operators can better appreciate its contribution to the engine’s overall performance and reliability.

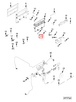

Role of Part 4298993 Studded Captive Washer Screw in Engine Systems

The part 4298993 studded captive washer screw is integral in securing various components within engine systems, ensuring stability and proper function. In the electronic control module (ECM) kit, this screw is utilized to fasten the module to the chassis or mounting bracket, providing a secure connection that withstands vibrations and environmental stresses. This is particularly important for the ECM, as any movement can lead to inaccurate readings or malfunctions in the engine’s electronic systems.

Within the engine control module (ECM), the 4298993 screw plays a role in attaching the module to its housing. This secure attachment is essential for maintaining the integrity of the electrical connections and ensuring that the module operates within specified parameters. The studded design of the screw allows for a captive washer, which prevents the screw from loosening over time due to engine vibrations, thus maintaining a consistent and reliable connection.

Furthermore, in engine systems where precise alignment and secure mounting are required, the 4298993 screw ensures that components remain in their designated positions. This is vital for the overall performance and longevity of the engine, as misaligned or loose components can lead to increased wear, reduced efficiency, and potential failure. The use of this screw in critical applications underscores its importance in maintaining the structural and functional integrity of engine systems.

Conclusion

The Studded Captive Washer Screw, part number 4298993, is a critical component in the automotive and heavy-duty truck industries, particularly in Cummins engines. Its design ensures secure fastening, resistance to vibration and corrosion, and ease of installation and maintenance. By understanding its role and importance, technicians and operators can ensure the reliability and longevity of engine systems.

-

Genta, G., & Morello, L. (2019). The Automotive Chassis Volume 1 Components Design Mechanical Engineering Series 2nd Edition. Springer.

↩ -

Bennett, S. (2012). Modern Diesel Technology: Light Duty Diesels. Cengage Learning.

↩ -

ElSayed, M. (2017). Fundamentals of Integrated Vehicle Realization. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.