3090936

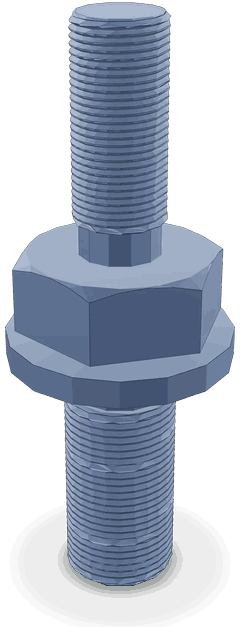

Studded Captive Washer Screw

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Studded Captive Washer Screw, identified by Part #3090936, is a specialized fastener produced by Cummins, a leading manufacturer in the automotive industry. This component is significant in the maintenance and operation of heavy-duty trucks, offering a reliable solution for fastening various components securely. Cummins is renowned for its high-quality truck components, and the Studded Captive Washer Screw is no exception, designed to meet the demanding requirements of heavy-duty applications 2.

Basic Concepts

A Studded Captive Washer Screw is a type of fastener that includes a threaded stud, a captive washer, and a screw head. The threaded stud allows for secure attachment into a pre-tapped hole, while the captive washer remains attached to the screw, preventing loss during installation and providing a uniform bearing surface. This design ensures consistent pressure distribution and enhances the fastening security of the components it joins 1.

Purpose and Role

In the operation of a truck, the Studded Captive Washer Screw plays a role by securing components that require a high degree of stability and resistance to vibration. It is particularly important in maintaining the structural integrity of the truck, as it ensures that critical components remain firmly in place under various driving conditions. Its application is widespread, from engine components to chassis parts, wherever secure fastening is required.

Key Features

The Studded Captive Washer Screw features a studded design that allows for easy installation into pre-tapped holes, ensuring a snug fit. The captive washer mechanism is integral to the screw, which means it cannot be misplaced during assembly. Additionally, the material composition of the screw is selected for its durability and resistance to corrosion, making it suitable for the harsh environments often encountered by heavy-duty trucks.

Benefits

Using a Studded Captive Washer Screw offers several advantages. Its design enhances durability, providing a secure fastening solution that resists loosening over time. The captive washer ensures consistent pressure distribution, which is vital for the longevity of the fastened components. Furthermore, its resistance to vibration and loosening makes it an ideal choice for applications where components are subject to dynamic loads.

Installation Process

Proper installation of the Studded Captive Washer Screw involves several steps to ensure optimal performance. First, the hole should be clean and free of debris. The screw is then inserted into the hole, and using a torque wrench, it is tightened to the manufacturer’s specified torque settings. Alignment is crucial during installation to ensure the screw engages properly with the mating component, providing a secure and stable connection.

Troubleshooting and Maintenance

Common issues with Studded Captive Washer Screws may include loosening due to vibration or corrosion. Regular inspection and maintenance can help identify these issues early. If loosening is detected, re-tightening to the specified torque settings is recommended. In cases of corrosion, replacing the screw may be necessary to maintain the integrity of the fastening.

Manufacturer Overview - Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a history spanning over a century, Cummins has established a reputation for producing high-quality, reliable components for the automotive industry. Their product range includes engines, powertrains, and components designed for heavy-duty applications, ensuring performance, efficiency, and durability in demanding environments 2.

Compatibility with Cummins Engines

The Studded Captive Washer Screw, part number 3090936, is a critical component in various Cummins engine models. This part is essential for securing and fastening different parts within the engine assembly, ensuring stability and reliability during operation.

I-Series Engines

The I-Series engines, including the ISC8.3 CM2250, ISL CM2150, ISL9 CM2150 SN, ISL9 CM2250, ISX CM570, ISX CM870, ISX CM871, and ISX12/ISX11.9 CM2250, all utilize the Studded Captive Washer Screw in their construction. This part is integral to the fastening mechanisms within these engines, ensuring that various components are securely held in place.

M-Series Engines

The M-Series engines, specifically the M11 CELECT, M11 CELECT PLUS, and QSM11 CM570, also incorporate the Studded Captive Washer Screw. This part is used in similar applications as in the I-Series engines, providing essential fastening and securing functions within the engine’s structure.

ISM Engines

The ISM CM570, ISM CM876, and ISM11 CM876 SN engines also rely on the Studded Captive Washer Screw. This part is crucial for maintaining the integrity of the engine assembly by ensuring that components are fastened securely and remain in place during operation.

Overall, the Studded Captive Washer Screw is a vital component across a wide range of Cummins engines, ensuring the reliability and performance of these powerful machines.

Role of Part 3090936 Studded Captive Washer Screw in Engine Systems

The 3090936 Studded Captive Washer Screw is an essential component in various engine systems, facilitating secure and reliable connections between different parts. Its design ensures that components remain firmly attached, which is vital for the engine’s performance and longevity.

Air Cleaner

In the air cleaner system, the 3090936 screw is used to attach the air cleaner housing to the engine block. This secure attachment ensures that the air intake system remains sealed, preventing unfiltered air from entering the engine and maintaining optimal air-fuel mixture ratios.

Crankcase Breather Plumbing

For the crankcase breather system, the screw plays a role in connecting the breather hoses to the cylinder block. This connection is important for venting crankcase gases, which helps in reducing pressure build-up and maintaining engine lubrication efficiency.

Cylinder Block

Within the cylinder block, the 3090936 screw is employed to fasten various components such as sensor brackets and mounting plates. This ensures that these elements remain stable and accurately positioned, contributing to the precise operation of the engine.

Engine Control Module (ECM)

The screw is also utilized in securing the engine control module to its mounting location. A stable ECM is essential for consistent signal transmission and accurate engine management, directly influencing overall engine performance.

Front Gear Housing

In the front gear housing, the 3090936 screw helps in attaching covers and plates, ensuring that the internal components are protected and aligned correctly. This is important for the smooth operation of the gear system and the prevention of mechanical failures.

Injectors

For fuel injectors, the screw is used to secure injector mounting brackets to the engine block. This ensures that injectors are held in place with the correct orientation, which is essential for precise fuel delivery and combustion efficiency.

Oil Cooler Water Plumbing

In the oil cooler water plumbing system, the screw connects the plumbing components to the engine block. This secure attachment is vital for maintaining the integrity of the cooling system, ensuring efficient heat exchange and engine temperature regulation.

Oil Fill Arrangement

Finally, in the oil fill arrangement, the 3090936 screw is used to attach the oil fill cap and associated components to the engine. This ensures a tight seal, preventing oil leaks and maintaining the engine’s lubrication system integrity.

Conclusion

The Studded Captive Washer Screw, part number 3090936, is a critical component in the maintenance and operation of heavy-duty trucks and Cummins engines. Its design and features ensure secure fastening, resistance to vibration and corrosion, and consistent pressure distribution, contributing to the reliability and performance of the engine systems it is part of. Proper installation, regular maintenance, and understanding its role in various engine components are essential for maximizing the effectiveness of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.