Minimum Quantity 4

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 4890875 Socket Head Cap Screw, manufactured by Cummins, is a specialized fastener designed for use in commercial truck maintenance and operation. Cummins, a well-established name in the commercial truck industry, produces a range of components that contribute to the efficiency and reliability of truck systems. This Cummins part plays a role in securing various parts within the truck’s mechanical assemblies.

Basic Concepts of Socket Head Cap Screws

A Socket Head Cap Screw is a type of fastener characterized by a hexagonal socket in the head, allowing it to be driven using a hex key. These screws are commonly used in mechanical assemblies to secure components due to their ability to provide a strong, permanent hold. They are preferred in applications where a flush or countersunk finish is required, and where high torque is needed without the risk of stripping the head 2.

Purpose of the 4890875 Socket Head Cap Screw in Truck Operation

In the context of commercial truck operation, the 4890875 Socket Head Cap Screw serves multiple functions. It is utilized in various truck systems to secure components that are subject to vibration and stress. This includes applications in the engine, transmission, and chassis, where maintaining a secure connection is vital for the truck’s performance and safety. The screw’s design allows for efficient tightening and loosening, facilitating easier maintenance and repair processes 1.

Key Features of the 4890875 Socket Head Cap Screw

The 4890875 Socket Head Cap Screw is engineered with specific design and material characteristics to enhance its effectiveness and durability in truck applications. It is typically made from high-strength steel, which provides the necessary tensile strength to withstand the rigors of truck operation. The screw’s hexagonal socket head design allows for high torque application without damaging the screw head, ensuring a secure and lasting connection.

Benefits of Using the 4890875 Socket Head Cap Screw

Utilizing the 4890875 Socket Head Cap Screw offers several advantages in truck maintenance and operation. Its design contributes to enhanced security of fastened components, reducing the risk of loosening under vibration. The ease of installation, facilitated by the hexagonal socket, allows for quick and efficient assembly and disassembly. Additionally, the material properties of the screw provide resistance to wear and corrosion, extending its service life in the demanding environment of commercial truck operation.

Installation and Usage Guidelines

Proper installation of the 4890875 Socket Head Cap Screw is crucial for ensuring optimal performance and longevity. It should be installed using the appropriate torque specifications to achieve the desired clamping force without over-tightening, which could lead to damage. The use of a hex key that fits snugly into the screw’s socket is recommended to prevent slippage and ensure even tightening. Regular inspection of the screw and its fastened components is advised to monitor for any signs of wear or loosening.

Troubleshooting Common Issues

Common issues with Socket Head Cap Screws may include loosening due to vibration, corrosion, or over-tightening leading to stripping of the socket. To address these problems, regular inspections should be conducted to identify any signs of wear or damage. In cases of corrosion, cleaning the affected area and applying a suitable anti-corrosive treatment can help. If the screw has been over-tightened, it may need to be replaced to ensure a secure connection.

Maintenance Tips

To prevent failure and extend the service life of the 4890875 Socket Head Cap Screw, regular maintenance is recommended. This includes periodic checks for signs of wear, corrosion, or loosening. Applying a lubricant to the screw can reduce friction and wear, especially in high-stress applications. Additionally, ensuring that the screw is installed with the correct torque specification will help maintain a secure connection and prevent over-tightening.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and focus on technological advancement have established it as a trusted partner in the commercial vehicle sector 2.

Socket Head Cap Screw 4890875 Compatibility with Cummins Engines

The Socket Head Cap Screw part number 4890875, manufactured by Cummins, is a versatile component that finds application across a range of Cummins engines. This screw is designed to secure various parts within the engine assembly, ensuring structural integrity and proper functioning.

D-Series Engines

The D-Series engines, including the D4.0 CM2620, D103B, F3.8 CM2350, F120B, F3.8 CM2620, F137B, F4.5 CM2620, F139B, and F4.5 CM2620, F141C, utilize the 4890875 screw in several key areas. These engines are known for their robust design and are commonly used in a variety of applications, from construction equipment to agricultural machinery. The screw is often used to fasten components such as valve covers, oil pans, and other critical parts that require a secure and reliable connection.

ISB/ISD Engines

The ISB/ISD engines, including the ISB CM850, ISB/ISD4.5 CM2150 B119, ISB/ISD6.7 CM2150 SN, ISBE CM2150, ISBE CM800, ISBE4 CM850, are another category where the 4890875 screw is extensively used. These engines are designed for heavy-duty applications and are found in large trucks, buses, and industrial equipment. The screw is used to secure components such as cylinder heads, intake manifolds, and other parts that need to withstand high stress and temperature.

ISF Engines

The ISF engines, including the ISF3.8 CM2220 AN, ISF3.8 CM2220 F103, ISF3.8 CM2350 F109, and ISF4.5 CM2220 F123, also benefit from the use of the 4890875 screw. These engines are typically used in medium-duty vehicles and equipment. The screw is used in various applications, such as fastening engine blocks, turbo housings, and other components that require a strong and reliable fastening solution.

QSB Engines

The QSB engines, including the QSB4.5 CM850 (CM2850), QSB6.7 CM850 (CM2850), and QSB7 CM2880 B117, are another group where the 4890875 screw is employed. These engines are designed for a wide range of applications, from construction equipment to marine vessels. The screw is used to secure components such as engine mounts, exhaust manifolds, and other parts that need to be tightly fastened to ensure optimal performance and durability.

QSF Engine

The QSF3.8 CM2880 F112 engine also utilizes the 4890875 screw. This engine is designed for specific applications where high performance and reliability are critical. The screw is used to secure various components, ensuring that the engine operates smoothly and efficiently under demanding conditions.

In summary, the Socket Head Cap Screw part number 4890875 is a critical component in the assembly and maintenance of a wide range of Cummins engines. Its versatility and reliability make it an essential part for securing various engine components across different engine series.

Role of Part 4890875 Socket Head Cap Screw in Engine Systems

The part 4890875 Socket Head Cap Screw is a vital fastening component utilized across various engine systems to ensure secure assembly and reliable operation.

In the base rail assembly, this screw plays a significant role in maintaining the structural integrity by securing the rail to the engine frame. Its precise fit and strong holding power are essential for withstanding the dynamic forces encountered during engine operation.

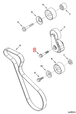

For the belt tensioner, the Socket Head Cap Screw is employed to fasten the tensioner mechanism to the engine block. This ensures consistent tension on the drive belt, which is necessary for the efficient transfer of power to auxiliary components such as the alternator and water pump.

In the drive system, these screws are often used to secure pulleys and sprockets, ensuring they remain aligned and operate smoothly. This is particularly important for maintaining the timing and efficiency of the engine’s accessory drives.

The water pump assembly also benefits from the use of Socket Head Cap Screws. They are used to attach the pump housing to the engine block, ensuring a leak-proof seal and stable operation under varying thermal conditions.

In the rail and base components, these screws provide the necessary clamping force to keep these parts firmly in place. This is essential for the overall stability and performance of the engine, especially under high-stress conditions.

Lastly, in the tensioner and belt systems, Socket Head Cap Screws are critical for adjusting and maintaining the correct tension on belts. This ensures optimal performance and longevity of the belt, reducing the risk of slippage or failure.

Overall, the part 4890875 Socket Head Cap Screw is an indispensable component in ensuring the secure and efficient operation of various engine systems.

Conclusion

The 4890875 Socket Head Cap Screw is a critical component in the maintenance and operation of commercial trucks and Cummins engines. Its design and material properties ensure secure fastening, resistance to wear and corrosion, and ease of installation and maintenance. Proper installation, regular inspection, and maintenance are essential for ensuring the longevity and reliability of this part in demanding truck and engine applications.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.