S121B

Hexagon Head Cap Screw

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins S121B Hexagon Head Cap Screw is a specialized fastener designed for use in commercial trucks. This part plays a significant role in truck maintenance and operation, ensuring the secure assembly of various components within the vehicle. Its robust design and high-quality construction make it a reliable choice for the demanding conditions encountered in heavy-duty truck applications.

Basic Concepts of Hexagon Head Cap Screws

A Hexagon Head Cap Screw is a type of fastener characterized by its hexagonal head, which allows for efficient tightening and loosening using a wrench or socket. The design of the cap screw includes a threaded shaft that engages with the internal threads of a nut or directly into a tapped hole in the material being fastened. Cap screws are commonly used in various industries for their strength and reliability in joining components.

Purpose of the S121B Hexagon Head Cap Screw in Truck Operation

The S121B is specifically designed to play a role in the operation and maintenance of commercial trucks. It is typically used in areas where secure and durable fastening is required, such as in the attachment of engine components, chassis parts, and other critical assemblies. Its application ensures that these components remain firmly in place, contributing to the overall safety and performance of the truck.

Key Features of the S121B Hexagon Head Cap Screw

The S121B features several distinctive characteristics that enhance its functionality and durability. These include a high-strength material composition, which provides resistance to wear and corrosion, a specific thread type that ensures a secure fit, and a hexagonal head design that facilitates easy installation and removal. These features collectively contribute to the screw’s ability to perform reliably in heavy-duty applications.

Benefits of Using the S121B Hexagon Head Cap Screw

The S121B offers several advantages over other types of fasteners. Its enhanced strength allows it to withstand significant loads without failure, while its resistance to loosening ensures that connections remain secure over time. Additionally, the ease of installation provided by its hexagonal head design makes it a practical choice for maintenance and repair tasks. When compared to other fasteners, the S121B stands out for its combination of strength, durability, and convenience.

Installation and Usage Guidelines

Proper installation of the S121B involves several steps to ensure a secure and lasting connection. Begin by selecting the appropriate size and type of screw for the application. Use a wrench or socket to tighten the screw to the recommended torque settings, which can be found in the manufacturer’s guidelines. It is important to avoid over-tightening, as this can lead to damage to the screw or the material being fastened.

Troubleshooting and Maintenance

Common issues with Hexagon Head Cap Screws include loosening over time and corrosion. Regular inspections can help identify these problems early, allowing for timely maintenance or replacement. To prolong the lifespan of the S121B, it is advisable to follow manufacturer-recommended maintenance practices, which may include periodic tightening and the application of anti-corrosion treatments.

Cummins: A Brief Overview

Cummins Inc. is a well-established manufacturer with a long history of producing high-quality components for the commercial truck industry. The company’s product range includes engines, powertrains, and various aftermarket parts, all designed with a commitment to quality and innovation. Cummins’ reputation for reliability and performance makes its components, including the S121B, a preferred choice for truck manufacturers and maintenance professionals alike.

Compatibility of the S121B with Cummins Engines

The S121B is a versatile component designed to fit a variety of Cummins engines. This part is engineered to meet the stringent requirements of industrial and commercial applications, ensuring reliability and durability. Below is a detailed description of its compatibility with specific Cummins engine models:

GTA38 G CMEICS G116C Series

The S121B screw is compatible with the GTA38 G CMEICS G116C engines, providing a secure fastening solution for various engine components. Its robust design ensures it can withstand the operational stresses of these engines.

K19, K38, K50 Series

The S121B screw is also suitable for the K19, K38, and K50 engines. These engines benefit from the screw’s precision and strength, which are critical for maintaining the integrity of engine assemblies.

KTA38GC CM558, NH/NT 855 Series

For the KTA38GC CM558 and NH/NT 855 engines, the S121B screw offers reliable fastening. Its compatibility with these models ensures that critical engine parts remain securely fastened under varying operational conditions.

QSK38 CM2150 MCRS, QSK38 CM850 MCRS, QSK45 CM500, QSK50 CM2150 K107, QSK50 CM2150 MCRS, QSK50 CM2350 K108, QSK60 CM500, QSK60 CM850 MCRS, QSK60G, QSK78 CM500, QST30 CM552 Series

The S121B screw is designed to fit the QSK38 CM2150 MCRS, QSK38 CM850 MCRS, QSK45 CM500, QSK50 CM2150 K107, QSK50 CM2150 MCRS, QSK50 CM2350 K108, QSK60 CM500, QSK60 CM850 MCRS, QSK60G, QSK78 CM500, and QST30 CM552 engines. This compatibility is crucial for maintaining the structural integrity of these engines, ensuring that all components are securely fastened and aligned.

V903 Series

Lastly, the S121B screw is also compatible with the V903 engines. Its design ensures that it can handle the specific demands of these engines, providing a reliable fastening solution that supports the engine’s operational efficiency.

Role of the S121B in Engine Systems

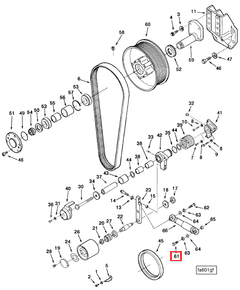

The S121B is integral to the secure assembly and operation of various engine components. Its robust design ensures reliable fastening across multiple applications within engine systems.

Alternator Mounting

In alternator mountings, the S121B screw secures the alternator to the engine block, ensuring stable operation and efficient power generation.

Turbocharger

For turbochargers, this screw is used to fasten the turbocharger housing to the engine, maintaining the integrity of the exhaust gas flow and boosting efficiency.

Base Parts

Base parts often require the S121B screw to anchor critical components to the engine frame, providing a solid foundation for other assemblies.

Bracket Clutch Cool Pump

In the bracket clutch cool pump arrangement, the screw ensures the clutch and pump are securely mounted, facilitating effective cooling and clutch operation.

Cleaner and Air Components

For air cleaner assemblies, the S121B screw fastens the cleaner to the engine, ensuring a tight seal and efficient air filtration.

Cooler Torque Converter

In cooler torque converter systems, this screw is essential for mounting the converter, ensuring smooth power transmission.

Drive and Fan Components

The screw is utilized in drive and fan arrangements to secure fan hubs and drive components, maintaining alignment and operational efficiency.

Exhaust Mounting Manifold

For exhaust mounting manifolds, the S121B screw ensures the manifold is firmly attached to the engine, preventing leaks and ensuring exhaust efficiency.

Filter and Lubricating Oil Systems

In filter and lubricating oil systems, the screw secures oil pans and sump pumps, critical for maintaining oil circulation and engine lubrication.

Flywheel Housing

The flywheel housing relies on the S121B screw for secure attachment to the engine, ensuring smooth rotational dynamics.

Module and Engine Control

Engine control modules often use this screw for secure mounting, guaranteeing the module’s stability and reliable performance.

Mounting Air Cleaner

For mounting air cleaners, the screw ensures the cleaner is firmly attached, maintaining optimal air intake.

Mounting Generator

Generator mountings use the S121B screw to secure the generator to the engine, ensuring consistent power output.

Mounting Tube L.O

In lubricating oil systems, the screw is used to mount tubes, ensuring secure and leak-free connections.

Oil Pan

The oil pan is fastened using the S121B screw, critical for containing lubricating oil and protecting engine components.

Plumbing Lubricating Oil Pump

For plumbing lubricating oil pumps, the screw ensures the pump is securely mounted, facilitating efficient oil distribution.

Radiator

Radiators often use this screw for secure attachment to the engine frame, ensuring effective cooling.

Separator Bracket

In separator brackets, the screw is used to mount fuel-water separators, critical for maintaining fuel purity.

Sump Pump

Sump pumps rely on the S121B screw for secure installation, ensuring efficient oil drainage.

System Auxiliary Cooling

Auxiliary cooling systems use this screw to mount components, ensuring effective temperature regulation.

Torque Converter

Torque converters are securely fastened using the S121B screw, maintaining efficient power transfer.

Tube Lubricating Oil Suction

In lubricating oil suction tubes, the screw ensures secure mounting, facilitating smooth oil flow.

Conclusion

The Cummins S121B Hexagon Head Cap Screw is a critical component in the maintenance and operation of commercial trucks. Its robust design, high-strength material composition, and ease of installation make it a reliable choice for securing various engine components. Proper installation and maintenance practices are essential to ensure the longevity and performance of this part in heavy-duty applications.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.