3049175

Hexagon Head Cap Screw

Cummins®

AVAILABLE

4 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Hexagon Head Cap Screw, a fundamental component in the realm of commercial trucks, is pivotal for ensuring the integrity and functionality of various truck systems. Manufactured by Cummins, a renowned name in the automotive industry, the Hexagon Head Cap Screw with part number 3049175 is specifically designed for heavy-duty truck applications. This part plays a role in the fastening mechanisms of commercial trucks, contributing to their overall performance and safety 1.

Basic Concepts of Hexagon Head Cap Screws

A Hexagon Head Cap Screw is a type of fastener characterized by its hexagonal head, which allows for efficient tightening and loosening using a wrench or socket. The design of the cap screw includes a threaded shaft that engages with internal threads in a mating part, providing a secure connection. In mechanical systems, cap screws are commonly used for fastening applications where high tensile strength and resistance to loosening are required 2.

Role of the 3049175 Hexagon Head Cap Screw in Truck Operation

The 3049175 Hexagon Head Cap Screw is integral to the operation and maintenance of commercial trucks. It is utilized in various applications where secure fastening is necessary, such as in the assembly of engine components, chassis parts, and other critical truck systems. By providing a robust connection, this screw contributes to the overall functionality and safety of the vehicle, ensuring that components remain securely in place under the demanding conditions of heavy-duty truck operation 3.

Key Features of the 3049175 Hexagon Head Cap Screw

The 3049175 Hexagon Head Cap Screw boasts several key features that enhance its performance and durability. It is composed of high-quality materials, typically a grade of steel that offers excellent strength and corrosion resistance. The screw features a specific thread type that ensures a tight and secure fit, and its design includes elements that prevent loosening over time, such as a chamfered underside and a flat seating surface. These features collectively contribute to the screw’s reliability in heavy-duty applications.

Benefits of Using the 3049175 Hexagon Head Cap Screw

Utilizing the 3049175 Hexagon Head Cap Screw offers several benefits. Its design allows for improved load distribution across the fastened components, enhancing the structural integrity of the assembly. The screw’s resistance to loosening ensures that connections remain secure over time, reducing the need for frequent maintenance. Additionally, the high-quality material composition provides durability and longevity, making it a cost-effective solution for commercial truck applications.

Installation and Usage Guidelines

Proper installation of the 3049175 Hexagon Head Cap Screw is crucial for ensuring a secure and lasting fastening solution. The installation process should follow specific torque specifications to achieve the correct tension without over-tightening, which could damage the screw or the mating part. Recommended tools for installation include a torque wrench and the appropriate socket or wrench for the hexagonal head. Best practices involve cleaning the mating surfaces before installation and periodically checking the tightness of the screw to maintain a secure connection.

Troubleshooting and Maintenance

Common issues associated with Hexagon Head Cap Screws include loosening over time and corrosion. To troubleshoot these issues, regular inspections should be conducted to ensure that screws remain tight and free from corrosion. Maintenance tips include applying a thread locker to prevent loosening and using corrosion-resistant coatings or materials to protect against environmental factors. Proper maintenance prolongs the life of the screw and ensures continued reliable performance.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history spanning over a century, Cummins is committed to quality and innovation in the automotive industry. The company’s extensive product range and dedication to excellence make it a trusted source for commercial truck components, ensuring that parts like the 3049175 Hexagon Head Cap Screw meet the high standards required for heavy-duty applications.

Hexagon Head Cap Screw 3049175 in Cummins Engines

The Cummins part number 3049175, a Hexagon Head Cap Screw, is a critical component in various Cummins engine models. This screw is integral to the assembly and maintenance of the engines, ensuring secure fastening of parts and components.

N14 CELECT and N14 MECHANICAL Engines

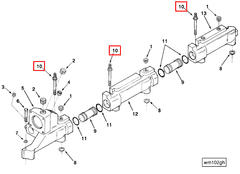

In the N14 CELECT and N14 MECHANICAL engines, the Hexagon Head Cap Screw 3049175 is utilized in several key areas. It is commonly used for securing engine covers, mounting brackets, and other structural components. The precision and strength of this screw are essential for maintaining the integrity of the engine’s internal and external structures, ensuring reliable operation and longevity.

NH/NT 855 Engines

Similarly, in the NH/NT 855 engines, the Hexagon Head Cap Screw 3049175 plays a vital role. It is employed in fastening various engine parts, including but not limited to, the engine block, cylinder heads, and ancillary components. This screw’s design ensures that these parts are held firmly in place, which is crucial for the engine’s performance and durability.

The use of the Hexagon Head Cap Screw 3049175 across these Cummins engines underscores its importance in maintaining the structural integrity and operational efficiency of the engines. Its application in securing critical components highlights the precision engineering that Cummins employs in its engine designs.

Role of Part 3049175 Hexagon Head Cap Screw in Engine Systems

The part 3049175 Hexagon Head Cap Screw is instrumental in securing various components within engine systems, ensuring their stability and proper function.

Manifold Assembly

In the manifold assembly, the Hexagon Head Cap Screw is used to fasten the manifold to the engine block. This secure attachment is essential for maintaining the integrity of the manifold, which is responsible for distributing air or exhaust gases to and from the combustion chambers.

Water Manifold and Water Mounting Manifold

The screw plays a significant role in the water manifold and water mounting manifold systems. It is employed to attach the water manifold to the engine block, ensuring a tight seal that prevents coolant leaks. This is vital for maintaining the engine’s temperature within optimal ranges, thereby enhancing performance and longevity.

Water Manifold Mounting

In the water manifold mounting setup, the Hexagon Head Cap Screw is utilized to secure the manifold to its designated mounting points. This ensures that the manifold remains firmly in place, allowing for efficient coolant flow and consistent engine cooling.

General Water System Components

Across various water system components, including the water manifold and water mounting manifold, the screw is essential for creating secure connections. It helps in maintaining the structural integrity of these components, which is necessary for the reliable operation of the engine’s cooling system.

By ensuring these connections are tight and secure, the Hexagon Head Cap Screw contributes to the overall efficiency and reliability of the engine systems it is a part of.

Conclusion

The 3049175 Hexagon Head Cap Screw is a critical component in the realm of commercial trucks and Cummins engines. Its design, featuring high-quality materials and specific thread types, ensures secure fastening and resistance to loosening. The screw’s application in various engine systems, including manifold assemblies and water manifolds, underscores its importance in maintaining the structural integrity and operational efficiency of these systems. Proper installation and maintenance of this Cummins part are essential for ensuring the longevity and reliability of commercial truck components.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.