This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Hexagon Head Cap Screw is a fundamental component in commercial truck maintenance, providing reliable fastening solutions across various applications. Manufactured by Cummins, a renowned name in the industry, the Hexagon Head Cap Screw part number 3010395 is designed to meet the demanding requirements of truck operations. This part plays a significant role in ensuring the structural integrity and functionality of commercial trucks, making it a vital element in maintenance and repair procedures 1.

Basic Concepts of Hexagon Head Cap Screws

A Hexagon Head Cap Screw is characterized by its hexagonal head, which allows for efficient tightening and loosening using standard tools such as wrenches or sockets. The design of the cap screw, with its threaded shaft and under-the-head flat seating surface, ensures a secure fit in applications where high tensile strength and resistance to loosening are required. Cap screws are widely used across industries for their versatility and reliability in fastening applications 2.

Purpose of the 3010395 Hexagon Head Cap Screw in Truck Operations

The 3010395 Hexagon Head Cap Screw is specifically engineered to address the unique demands of commercial truck assemblies. It is commonly used in applications where strong, durable fastening is required, such as in the attachment of engine components, chassis parts, and various structural elements. Its role in truck operations is to provide a secure and lasting connection, contributing to the overall safety and performance of the vehicle 3.

Key Features of the 3010395 Hexagon Head Cap Screw

The 3010395 Hexagon Head Cap Screw boasts several distinctive characteristics that enhance its functionality and durability. It is made from high-quality materials, ensuring resistance to corrosion and wear. The screw features a specific thread type that offers optimal engagement with mating parts, and its head design facilitates easy installation and removal with standard tools. These features collectively contribute to the screw’s ability to maintain a secure fastening under various operating conditions 1.

Benefits of Using the 3010395 Hexagon Head Cap Screw

Utilizing the 3010395 Hexagon Head Cap Screw in truck maintenance offers several advantages. Its design provides improved fastening strength, ensuring that components remain securely attached even under stress. The screw’s compatibility with standard tools simplifies the installation and removal process, enhancing efficiency during maintenance procedures. Additionally, its resistance to loosening helps maintain the integrity of fastenings over time, reducing the need for frequent re-tightening 2.

Installation and Usage Guidelines

Proper installation of the 3010395 Hexagon Head Cap Screw is crucial for ensuring a secure fit. It is recommended to follow manufacturer-specified torque settings to achieve the correct tension without over-tightening, which could damage the screw or the mating part. Using the appropriate tools and techniques during installation will help prevent stripping or cross-threading, ensuring the screw functions as intended 3.

Troubleshooting Common Issues

Common issues associated with Hexagon Head Cap Screws include stripping and corrosion. To address stripping, it is important to use the correct size tool and apply even pressure during tightening. Corrosion can be mitigated by selecting screws made from corrosion-resistant materials and by applying protective coatings where necessary. Regular inspection of screws can help identify when replacement is needed to prevent further damage 1.

Maintenance Tips

To prolong the life of the 3010395 Hexagon Head Cap Screw, regular maintenance practices should be observed. This includes routine inspections for signs of wear or damage, cleaning to remove dirt and debris that could lead to corrosion, and ensuring that screws are tightened to the proper torque specifications. Using the correct tools and techniques during maintenance will help preserve the integrity of the screw and the components it secures 2.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history in the commercial truck industry, Cummins is committed to delivering high-quality, innovative solutions that meet the needs of its customers. The company’s dedication to excellence is evident in its wide range of truck components, including the 3010395 Hexagon Head Cap Screw, which embodies Cummins’ standards for quality and performance 3.

Hexagon Head Cap Screw 3010395 Compatibility with Cummins Engines

The Hexagon Head Cap Screw 3010395 by Cummins is a versatile component designed to fit a variety of Cummins engines. This screw is engineered to provide a secure fastening solution, ensuring the integrity and functionality of engine components. Here is a breakdown of its compatibility with specific Cummins engines:

G855 Series

- G855

- G855 CM558

- GTA855 CM558 (CM2358)

The G855 series engines, including the G855, G855 CM558, and GTA855 CM558 (CM2358), benefit from the use of the Hexagon Head Cap Screw 3010395. This screw is typically used in applications where a robust and reliable fastening method is required, such as securing engine covers, brackets, and other critical components.

G101 Series

- G101

The G101 engine also integrates the Hexagon Head Cap Screw 3010395 in its assembly. This screw is essential for maintaining the structural integrity of the engine by providing a dependable fastening solution for various engine parts.

K19 Series

- K19

In the K19 engine, the Hexagon Head Cap Screw 3010395 is utilized to secure several engine components. Its design ensures that the screw can withstand the operational stresses and provide a long-lasting fastening solution.

KTA19 Series

- KTA19GC

The KTA19GC engine incorporates the Hexagon Head Cap Screw 3010395 in its design. This screw is critical for fastening parts that require a high level of precision and durability, ensuring the engine operates efficiently and reliably.

N14 Series

- N14 CELECT

- N14 G

- N14 MECHANICAL

The N14 series engines, including the N14 CELECT, N14 G, and N14 MECHANICAL, utilize the Hexagon Head Cap Screw 3010395 for various fastening applications. This screw is essential for securing components that are subject to significant mechanical stress, ensuring the engine’s longevity and performance.

NH/NT 855 Series

- NH/NT 855

The NH/NT 855 engine also relies on the Hexagon Head Cap Screw 3010395 for its assembly. This screw is used in applications where a strong and reliable fastening method is necessary, contributing to the overall reliability and durability of the engine.

Role of Part 3010395 Hexagon Head Cap Screw in Engine Systems

The part 3010395 Hexagon Head Cap Screw is integral to the assembly and maintenance of various engine components. Its primary function is to secure and fasten different parts together, ensuring structural integrity and proper operation of the engine system.

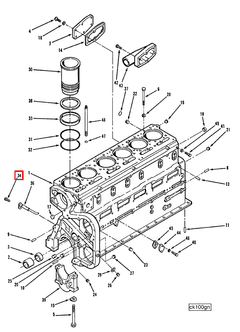

Base Parts and Blocks

In the context of base parts and blocks, the Hexagon Head Cap Screw is used to fasten the base to the engine block. This secures the foundational elements of the engine, providing a stable platform for other components to be mounted.

Cylinder and Short Blocks

For cylinder and short blocks, such as the KTTA-19C, NTC-300, NTC-350, and NTC-400, the screw plays a vital role in attaching the cylinder to the block. This ensures that the cylinder is held firmly in place, which is essential for the engine’s combustion process.

Cylinder Head Conversion Kit

In cylinder head conversion kits, the Hexagon Head Cap Screw is employed to secure the cylinder head to the engine block. This is important for maintaining the seal between the head and block, which is necessary for proper compression and combustion.

Freon Compressor Mounting

For components like the freon compressor mounting bracket, the screw is used to attach the compressor to its designated location on the engine. This ensures that the compressor remains stable and operates efficiently.

Gasket and Lubricating Pump Conversion Kits

In gasket kits and lubricating pump conversion kits, the screw is utilized to secure gaskets and pump components. This helps in maintaining the integrity of seals and the efficient operation of the lubrication system.

Main Bearing Shell and Piston Components

The screw is also crucial in securing main bearing shells and piston components, such as the piston cooling hole plug and mounting nozzle. This ensures that these elements remain in place, contributing to the smooth operation of the engine.

Short Assembly and Performance Parts

In short assembly blocks and performance parts, the Hexagon Head Cap Screw is used to fasten various components, ensuring that the engine maintains its structural integrity and performs optimally.

PDC and Other Kits

For PDC (Powertrain Control Module) and other kits, the screw is essential in securing electronic and mechanical components, ensuring they are correctly installed and function as intended.

Overall, the part 3010395 Hexagon Head Cap Screw is a fundamental fastening component across a wide range of engine systems, contributing to the reliability and performance of the engine.

Conclusion

The 3010395 Hexagon Head Cap Screw by Cummins is a critical component in the maintenance and operation of commercial trucks and various engine systems. Its design, featuring high-quality materials and a hexagonal head for efficient tightening, ensures reliable fastening across demanding applications. Proper installation, regular maintenance, and understanding its role in different engine components are essential for maximizing its effectiveness and longevity.

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.