This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3001510 Hexagon Head Cap Screw is a specialized fastener designed for commercial truck applications. Cummins, a prominent name in the commercial truck industry, is renowned for its commitment to quality and innovation. This part is significant due to its role in ensuring the secure assembly and reliable operation of various truck components.

Basic Concepts of Hexagon Head Cap Screws

A Hexagon Head Cap Screw is characterized by its hexagonal head, which allows for efficient tightening and loosening using a wrench or socket. The hexagonal design provides a greater contact area compared to other head types, reducing the risk of cam-out and enabling higher torque application. This screw type is commonly used in applications requiring a permanent fastening solution 1.

Purpose of the 3001510 Hexagon Head Cap Screw in Truck Operations

The 3001510 Hexagon Head Cap Screw is utilized in various truck assemblies, including engine components, chassis parts, and body panels. Its primary function is to provide a strong, durable connection that can withstand the rigors of heavy-duty truck operations 2.

Key Features

This Cummins part is crafted from high-quality materials, ensuring durability and reliability. It features a specific thread type designed for optimal engagement with mating components. Additionally, it may include special coatings or treatments to enhance corrosion resistance and facilitate easier installation and removal 3.

Benefits

Using the 3001510 Hexagon Head Cap Screw offers several advantages. Its durable construction ensures long-lasting performance, while any corrosion-resistant coatings help protect against environmental factors. The design of the screw also allows for straightforward installation and removal, reducing maintenance time and effort.

Installation Guidelines

Proper installation of the 3001510 Hexagon Head Cap Screw involves several steps. First, ensure the mating surfaces are clean and free of debris. Use the appropriate wrench or socket to tighten the screw to the specified torque, which can be found in the manufacturer’s guidelines. It is important to avoid over-tightening, which can damage the screw or the component being fastened.

Troubleshooting and Maintenance

Common issues with Hexagon Head Cap Screws include loosening over time and corrosion. To address these, regularly inspect screws for signs of wear or corrosion and tighten as necessary. If corrosion is present, consider replacing the screw to prevent further damage. Proper maintenance can help ensure the longevity and proper function of these fasteners.

Comparison with Other Fasteners

When compared to other types of fasteners, the 3001510 Hexagon Head Cap Screw offers distinct advantages. Its hexagonal head design allows for more efficient tightening and reduced risk of cam-out. However, other fasteners may be more suitable in scenarios where a different head type or thread engagement is required.

Safety Considerations

When using and maintaining Hexagon Head Cap Screws, it is important to follow safety guidelines. This includes proper handling to avoid injury, storing screws in a dry, secure location, and using them within the specified parameters to ensure safety and performance.

Cummins: Manufacturer Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its innovative products and commitment to quality. The company has a long history of providing reliable components for heavy-duty applications, and its reputation is built on a foundation of excellence and customer satisfaction.

Role of Part 3001510 Hexagon Head Cap Screw in Engine Systems

The 3001510 Hexagon Head Cap Screw is integral to the assembly and functionality of various engine components. Its primary role is to secure and maintain the integrity of connections within the engine system.

In the context of base parts and base part assemblies, the 3001510 screw ensures that the foundational elements are firmly attached, providing stability and preventing any shifting during operation. This is particularly important in high-performance engines where precision and reliability are paramount.

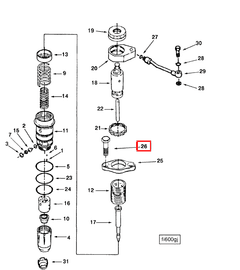

For EBM-injector systems, the screw is used in the injector mounting process. It secures the injector to the engine block or cylinder head, ensuring a tight seal and proper alignment. This is essential for the injector to function correctly, delivering fuel at the right time and in the right amount.

Within EBM-parts and performance parts, the 3001510 screw plays a similar role. It is often found in high-stress areas where components need to withstand significant forces and vibrations. Its use in these applications helps maintain the structural integrity and performance of the engine.

In an engine installation kit, the 3001510 screw is a common fastener used to assemble various components. Whether it’s attaching the base to the engine block or securing performance parts, its reliability and strength make it a preferred choice for engineers and mechanics.

Conclusion

The 3001510 Hexagon Head Cap Screw is a versatile and reliable component in engine systems, contributing to the secure assembly and reliable operation of numerous parts. Its design and construction ensure that it can withstand the operational rigors of heavy-duty engines, providing a dependable fastening solution that enhances the overall performance and longevity of the engines.

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.