177020

Hexagon Head Cap Screw

Cummins®

IN STOCK

1 is currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Hexagon Head Cap Screw is a fundamental component in the realm of commercial trucks, providing secure fastening solutions that are vital for the integrity and performance of truck assemblies. Manufactured by Cummins, a renowned name in the industry, the Hexagon Head Cap Screw part number 177020 is specifically designed for various applications within commercial trucks. This part plays a significant role in ensuring the reliability and durability of truck components, contributing to the overall efficiency and safety of truck operations 1.

Basic Concepts of Hexagon Head Cap Screws

A Hexagon Head Cap Screw is characterized by its hexagonal head, which allows for efficient tightening and loosening using a wrench or socket. This design ensures a firm grip, reducing the risk of slippage during installation. Cap screws, in general, are used in mechanical assemblies where a threaded fastener is required to join components securely. They are often used in applications where high tensile strength and resistance to loosening are necessary 2.

Purpose of the 177020 Hexagon Head Cap Screw in Truck Operations

The 177020 Hexagon Head Cap Screw is integral to the operation and maintenance of commercial trucks. It is employed in various fastening applications where secure and durable connections are required. The screw’s role in truck components ensures that parts remain firmly attached under varying conditions, which is crucial for the safe and efficient operation of the vehicle. Secure fastening is particularly important in areas subjected to vibration, stress, or environmental factors that could compromise the integrity of the assembly 3.

Key Features of the 177020 Hexagon Head Cap Screw

The 177020 Hexagon Head Cap Screw boasts several key features that enhance its functionality and durability. It is crafted from high-quality materials, typically alloy steel, which provides excellent strength and resistance to wear. The screw features a coarse thread, which allows for quick and secure fastening. Its hexagonal head is designed for compatibility with standard tools, ensuring ease of use during installation and removal. These features collectively contribute to the screw’s ability to withstand the demanding conditions encountered in commercial truck applications 4.

Benefits of Using the 177020 Hexagon Head Cap Screw

Utilizing the 177020 Hexagon Head Cap Screw in truck maintenance and repair offers several advantages. The screw’s enhanced strength ensures that it can withstand significant loads and stresses, making it suitable for critical applications. Its corrosion resistance prolongs the lifespan of the fastener, even in harsh environments. Additionally, the screw’s design allows for easy installation and removal using common tools, streamlining maintenance procedures and reducing downtime 1.

Installation and Usage Guidelines

Proper installation of the 177020 Hexagon Head Cap Screw is crucial for ensuring a secure fit. Begin by cleaning the mating surfaces to remove any debris or contaminants. Insert the screw into the pre-drilled hole, ensuring it is aligned correctly. Use a wrench or socket to tighten the screw gradually, applying even pressure to avoid cross-threading. Torque settings should be adhered to as specified by the manufacturer to achieve the optimal tension without overtightening, which could damage the screw or the surrounding components 2.

Troubleshooting and Maintenance

Common issues with Hexagon Head Cap Screws include loosening over time due to vibration or insufficient torque during installation. To troubleshoot, inspect the screw and surrounding components for signs of wear or damage. Re-tighten the screw to the recommended torque settings if necessary. Regular maintenance, such as periodic checks for tightness and corrosion, can help prolong the life of the screw and ensure ongoing reliability. In cases of significant wear or damage, replacement may be required to maintain the integrity of the assembly 3.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history dating back to 1919, Cummins has established itself as a trusted name in the commercial truck industry. The company is committed to quality and innovation, consistently delivering high-performance components that meet the rigorous demands of commercial applications. Cummins’ dedication to excellence ensures that their products, including the 177020 Hexagon Head Cap Screw, are reliable and durable, contributing to the success and safety of truck operations worldwide 4.

Cummins Hexagon Head Cap Screw 177020 in Engine Applications

The Cummins Hexagon Head Cap Screw, part number 177020, is a critical component in various engine configurations. This screw is designed to provide secure fastening, ensuring that engine components remain tightly secured under operational stresses.

K19, K38, and K50 Engines

In the K19, K38, and K50 engines, the 177020 screw is often used in applications where high-strength fastening is required. These engines, known for their robust design, benefit from the screw’s ability to maintain integrity under high-temperature and high-pressure conditions. The screw’s hex head allows for easy and efficient tightening using standard tools, ensuring that maintenance and assembly processes are streamlined 1.

N14 MECHANICAL Engine

For the N14 MECHANICAL engine, the 177020 screw is utilized in several key areas. Its application in this engine includes securing various engine components, such as the cylinder head and valve covers, ensuring that these parts remain firmly attached during operation. The screw’s design provides the necessary strength and durability to withstand the rigors of continuous engine operation 2.

NH/NT 855 Engine

In the NH/NT 855 engine, the 177020 screw is employed in both structural and functional applications. It is used to fasten components that are subject to significant mechanical stress, ensuring that these parts remain securely in place. The screw’s hex head design facilitates easy access and adjustment, which is crucial during maintenance procedures 3.

QSNT14 CM876 N102 Engine

The QSNT14 CM876 N102 engine also leverages the 177020 screw in its design. This engine, which is part of a series known for its reliability and performance, uses the screw in various fastening applications. Its use in this engine ensures that critical components are held together securely, contributing to the overall stability and longevity of the engine 4.

Role of Part 177020 Hexagon Head Cap Screw in Engine Systems

The part 177020 Hexagon Head Cap Screw is integral to the assembly and functionality of various engine components. Its robust design ensures secure fastening, which is essential for the reliable operation of the engine system.

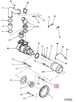

Drive Gear Mounting Pump

In the drive gear mounting pump, the Hexagon Head Cap Screw secures the drive gear to the pump housing. This connection is vital for the efficient transfer of power from the engine to the pump, ensuring consistent fluid movement throughout the system 1.

EBM: Manifold

For the Exhaust Brake Manifold (EBM), the screw plays a role in attaching the manifold to the engine block. This secure attachment is necessary for maintaining the integrity of the exhaust system and ensuring that exhaust gases are directed efficiently 2.

Water Manifold and Water Manifold Mounting

In the water manifold and its mounting, the screw is used to fasten the manifold to the engine block or other components. This ensures a leak-free connection, which is essential for the proper circulation of coolant throughout the engine 3.

Fan Drive and Fan Drive 1.0 11.5 Ctr

For the fan drive and its variants, the screw secures the fan to the drive mechanism. This attachment is crucial for the effective cooling of the engine, as it ensures that the fan operates smoothly and efficiently 4.

Fuel Plumbing and Fuel Bypass

In fuel plumbing and fuel bypass systems, the screw is employed to fasten components such as fittings and brackets. This secures the fuel lines and ensures that fuel is delivered consistently and without leaks 1.

Kit 2-Sea Water Pump and Raw Water Pump

For the kit 2-sea water pump and raw water pump, the screw is used to attach the pump housing to the engine or other mounting points. This ensures that the pump operates efficiently and that seawater or raw water is circulated effectively for cooling purposes 2.

Rocker Lever and Support Mounting

In the rocker lever and support mounting, the screw secures these components to the engine block or other structural elements. This ensures that the rocker lever operates smoothly and that the support structure remains stable under engine vibrations 3.

Exhaust Manifold

For the exhaust manifold, the screw is used to attach the manifold to the engine block. This secure connection is vital for directing exhaust gases away from the engine efficiently and maintaining the structural integrity of the exhaust system 4.

Conclusion

The part 177020 Hexagon Head Cap Screw, through its applications in these components, ensures the secure and efficient operation of the engine system. Its reliability and strength make it a key element in maintaining the performance and durability of various engine components.

-

Ling, Frederick F. The Automotive Body. Springer Science, 2011.

↩ ↩ ↩ ↩ ↩ -

Heywood, John. Internal Combustion Engine Fundamentals. McGraw-Hill Education, 2019.

↩ ↩ ↩ ↩ ↩ -

Hu, Haoran, Rudy Smaling, and Simon Baseley. Heavy-Duty Wheeled Vehicles. SAE International, 2014.

↩ ↩ ↩ ↩ ↩ -

Calder, Nigel. Diesel Engine Care and Repair. The McGraw-Hill Companies, 2007.

↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.