This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

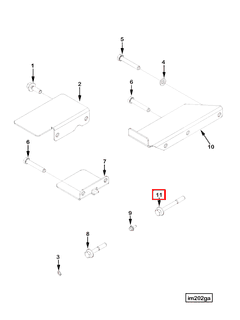

The Cummins Captive Washer Cap Screw, part number 4022819, is a specialized fastener designed for commercial truck applications. Cummins, a prominent name in the automotive and heavy-duty truck industry, manufactures this component to meet the demanding requirements of commercial vehicles. This part is significant due to its role in ensuring secure and reliable fastening in various truck components.

Basic Concepts of Captive Washer Cap Screws

A Captive Washer Cap Screw is a fastener that includes an integrated washer. This design ensures that the washer remains in place during installation, reducing the risk of loss and simplifying the fastening process. The components of a Captive Washer Cap Screw typically include the screw itself, the integrated washer, and a hexagonal head for easy turning. In fastening applications, the screw threads into a pre-tapped hole, while the integrated washer provides a uniform distribution of clamping force, enhancing the stability and integrity of the joint 1.

Purpose of the 4022819 Captive Washer Cap Screw

The 4022819 Captive Washer Cap Screw is utilized in the operation and maintenance of commercial trucks to secure various components. It is commonly used in applications where consistent and reliable fastening is required, such as in the attachment of engine components, body panels, and chassis parts. The integrated washer ensures that the clamping force is evenly distributed, which is crucial for maintaining the structural integrity and performance of the truck 2.

Key Features

The 4022819 Captive Washer Cap Screw boasts several key features that enhance its performance. Its design includes an integrated washer that prevents the washer from being misplaced during installation. The screw is typically made from high-strength materials, such as alloy steel, to withstand the rigors of commercial truck use. Additionally, the hexagonal head allows for easy installation and removal using standard tools, ensuring convenience and efficiency in maintenance procedures 3.

Benefits

Using the 4022819 Captive Washer Cap Screw offers several benefits. The integrated washer simplifies the installation process by eliminating the need to handle separate washers, reducing the risk of errors and improving efficiency. The high-strength material ensures durability and reliability, even under demanding conditions. Furthermore, the consistent clamping force provided by the integrated washer enhances the stability and longevity of the fastened components, contributing to overall vehicle reliability.

Installation Process

Proper installation of the 4022819 Captive Washer Cap Screw involves several steps. First, ensure that the mating surface is clean and free of debris. Next, align the screw with the pre-tapped hole and begin threading it in by hand to avoid cross-threading. Once the screw is started, use a torque wrench to tighten it to the specified torque setting, ensuring that the correct clamping force is achieved without over-tightening. Finally, double-check the installation to confirm that the screw is secure and the integrated washer is properly seated.

Troubleshooting and Maintenance

Common issues with the 4022819 Captive Washer Cap Screw may include loosening over time due to vibration or corrosion. To address these issues, regularly inspect the screws during routine maintenance checks. If loosening is detected, re-tighten the screw to the specified torque setting. In cases of corrosion, clean the affected area and consider applying a corrosion-resistant coating to prevent further issues. Regular maintenance and timely replacement of worn screws will ensure longevity and optimal performance.

Comparison with Standard Cap Screws

When comparing the 4022819 Captive Washer Cap Screw to standard cap screws, several advantages become apparent. The integrated washer in the Captive Washer Cap Screw simplifies the installation process and ensures consistent clamping force, reducing the risk of errors and enhancing joint stability. Standard cap screws, while versatile, require separate washers, which can be misplaced or installed incorrectly. The Captive Washer Cap Screw is preferable in applications where reliability and ease of installation are paramount, such as in commercial truck maintenance.

Cummins: A Brief Overview

Cummins is a renowned manufacturer with a rich history in the automotive and heavy-duty truck industry. Established in 1919, Cummins has built a reputation for quality, innovation, and reliability in engine and component manufacturing. Their commitment to excellence is evident in their extensive product line, which includes a variety of high-performance parts designed to meet the rigorous demands of commercial vehicles. Cummins’ dedication to quality and customer satisfaction has solidified their position as a leader in the industry.

Captive Washer Cap Screw (Part 4022819) in Cummins Engines

The Captive Washer Cap Screw, identified by part number 4022819, is a critical component in the assembly and maintenance of various Cummins engines. This part is integral to the structural integrity and operational efficiency of the engines it is used in.

ISM CM570

In the ISM CM570 engine, the Captive Washer Cap Screw is utilized in several key areas. It is often employed in securing components that require a high level of stability and resistance to vibration. This includes fastening parts of the engine block, ensuring that all components remain tightly secured under the high stress conditions typical of engine operation.

ISM11 CM876 SN

Similarly, in the ISM11 CM876 SN engine, the Captive Washer Cap Screw is used to maintain the integrity of the engine’s structure. This engine, like the ISM CM570, benefits from the reliability and durability of the 4022819 part. It is particularly important in areas where the prevention of loosening due to vibration is critical, such as in the attachment of engine mounts and other critical assemblies.

Grouping of Engines

Both the ISM CM570 and ISM11 CM876 SN engines share common design philosophies and engineering principles, which is why the Captive Washer Cap Screw is a suitable fit for both. The use of this part in these engines highlights its versatility and importance in ensuring the longevity and performance of Cummins engines. The screw’s design allows it to maintain a secure hold, even in the demanding environments these engines operate in.

Role of Part 4022819 Captive Washer Cap Screw in Engine Systems

The part 4022819 Captive Washer Cap Screw is integral to the secure and efficient operation of various engine components. In the context of an engine arrangement, this screw ensures that components are held firmly in place, minimizing the risk of displacement or misalignment during operation.

In turbocharger systems, the 4022819 screw is often used to secure the turbocharger to its mounting bracket. This secure attachment is vital for maintaining the turbocharger’s alignment and ensuring it operates within its designed parameters, thereby enhancing overall engine performance.

When considering the drive components, the 4022819 screw plays a role in attaching drive pulleys or gears to their respective shafts. This secure fitting is essential for transmitting power efficiently throughout the engine system, reducing the likelihood of slippage or failure under load.

In fan assemblies, the 4022819 screw is utilized to attach the fan blades to the fan hub. This ensures that the fan operates smoothly and effectively, contributing to the engine’s cooling system by maintaining consistent airflow over critical components.

For mounting purposes, the 4022819 screw is commonly employed to secure various engine components to the engine block or chassis. This includes attaching the air intake manifold, where a stable and vibration-resistant connection is necessary to prevent air leaks and ensure optimal air flow into the engine.

Overall, the 4022819 Captive Washer Cap Screw is a fundamental component in ensuring the structural integrity and operational efficiency of engine systems. Its application across different components underscores its versatility and importance in maintaining the performance and reliability of the engine.

Conclusion

The 4022819 Captive Washer Cap Screw is a vital component in the maintenance and operation of commercial trucks and Cummins engines. Its design, featuring an integrated washer and high-strength materials, ensures reliable and secure fastening in demanding applications. The benefits of using this part include simplified installation, enhanced joint stability, and improved durability. Proper installation and regular maintenance are essential to ensure the longevity and performance of the fastened components. Cummins’ reputation for quality and innovation is reflected in the design and functionality of this part, making it a critical element in the structural integrity and operational efficiency of engine systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.