3082523

Captive Washer Cap Screw

Cummins®

AVAILABLE

4 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Captive Washer Cap Screw, part number 3082523, manufactured by Cummins, is a specialized fastener designed for use in commercial trucks. Cummins, a well-established name in the commercial truck industry, produces a range of components that enhance the performance and reliability of heavy-duty vehicles. This part is integral to the assembly and maintenance of these trucks, providing a secure fastening solution for various components.

Basic Concepts of Captive Washer Cap Screws

A Captive Washer Cap Screw is a type of fastener that includes an integrated washer, which is held in place by a protrusion or step on the screw shaft. This design ensures that the washer remains attached to the screw, reducing the risk of loss during installation and providing consistent and reliable fastening. The components of a Captive Washer Cap Screw typically include the screw head, the threaded shaft, and the captive washer. The screw functions by threading into a pre-drilled hole, where the washer distributes the load and prevents damage to the fastened material 1.

Purpose of the 3082523 Captive Washer Cap Screw in Truck Operations

The 3082523 Captive Washer Cap Screw plays a role in the assembly and maintenance of commercial trucks by securing various components. It is used in applications where consistent and reliable fastening is required, such as attaching panels, securing brackets, and fastening engine components. The integrated washer helps distribute the clamping force evenly, reducing the risk of damage to the fastened materials and ensuring a secure connection 2.

Key Features

The 3082523 Captive Washer Cap Screw features a design that includes a hexagonal head for easy installation using standard tools. The screw is made from high-strength materials, ensuring durability in demanding truck environments. The captive washer is securely attached to the screw shaft, providing a consistent and reliable fastening solution. Additionally, the screw is coated to resist corrosion, enhancing its performance in various operating conditions 3.

Benefits of Using the 3082523 Captive Washer Cap Screw

The 3082523 Captive Washer Cap Screw offers several advantages. Its design ensures reliable fastening, reducing the risk of component failure. The integrated washer simplifies the installation process, as there is no need to handle separate washers. The high-strength material and corrosion-resistant coating enhance the screw’s durability, making it suitable for use in harsh truck environments. Additionally, the consistent performance of the captive washer helps maintain the integrity of fastened components over time 4.

Installation Process

To install the 3082523 Captive Washer Cap Screw, begin by ensuring the fastening surface is clean and free of debris. Use a drill to create a pilot hole that matches the diameter of the screw. Position the screw over the hole and use a socket wrench to drive it in until the head is flush with the surface. Ensure the screw is tightened to the manufacturer’s specified torque to achieve optimal clamping force without over-tightening, which could damage the fastened materials 5.

Troubleshooting Common Issues

Common issues with the 3082523 Captive Washer Cap Screw may include difficulty in installation, loosening over time, or corrosion. To address installation difficulties, ensure the pilot hole is the correct size and that the screw is aligned properly. If the screw loosens, check for vibrations or movement in the fastened components and consider using a lock washer or thread locker for additional security. Corrosion can be mitigated by ensuring the screw is coated and by regularly inspecting and maintaining the fastened area to prevent moisture buildup 6.

Maintenance Tips

To maintain the 3082523 Captive Washer Cap Screw, regularly inspect the fastened area for signs of wear, corrosion, or loosening. Clean the area to remove any debris or contaminants that could affect the screw’s performance. If corrosion is present, consider applying a corrosion-resistant coating or replacing the screw if necessary. Ensure that all fastened components remain secure and that the screw is tightened to the proper torque to maintain reliable performance 7.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. Founded in 1919, Cummins has a long history of innovation and excellence in the commercial truck industry. The company offers a wide range of products, including engines, powertrains, and aftermarket parts, known for their reliability and performance. Cummins is recognized for its commitment to quality and customer satisfaction, making it a trusted name in the industry 8.

Captive Washer Cap Screw in Cummins Engines

The Captive Washer Cap Screw, part number 3082523, manufactured by Cummins, is a critical component in several of their engine models. This part is designed to secure various engine parts and assemblies, ensuring they remain tightly fastened and properly aligned during operation.

G855

In the G855 engine, the Captive Washer Cap Screw is utilized in several key areas. It is often employed to secure the cylinder head to the engine block, ensuring a tight seal and preventing any potential leaks. Additionally, it may be used in the assembly of the intake and exhaust manifolds, as well as in the fastening of various engine brackets and supports.

N14 CELECT PLUS and N14 MECHANICAL

For both the N14 CELECT PLUS and N14 MECHANICAL engines, the Captive Washer Cap Screw plays a vital role in maintaining the structural integrity of the engine. This part is commonly used in the fastening of the cylinder heads, ensuring they are securely attached to the engine block. It is also used in the assembly of the intake and exhaust manifolds, as well as in the mounting of various engine accessories and components.

QSN14 CM876 N103

In the QSN14 CM876 N103 engine, the Captive Washer Cap Screw is essential for the proper assembly and operation of the engine. It is used to secure the cylinder heads, ensuring a tight seal and preventing any potential leaks. Additionally, it is employed in the fastening of the intake and exhaust manifolds, as well as in the mounting of various engine brackets and supports. This part is crucial for maintaining the overall structural integrity of the engine.

The Captive Washer Cap Screw part number 3082523 is a reliable and essential component in the Cummins engine lineup, ensuring the secure assembly and operation of various engine parts and assemblies.

Role of Part 3082523 Captive Washer Cap Screw in Engine Systems

In the intricate assembly of engine systems, the 3082523 Captive Washer Cap Screw plays a significant role in ensuring the secure attachment and alignment of various components. This screw is instrumental in maintaining the structural integrity and operational efficiency of the engine.

Integration with the Cylinder Block

The cylinder block, the foundational structure of an engine, relies on precise fastening to ensure all components are correctly aligned and securely attached. The 3082523 Captive Washer Cap Screw is often used to fasten ancillary components to the cylinder block, providing a stable base for other parts to function effectively.

Securing the Follower and Cam

In the valve train mechanism, the follower and cam work in tandem to control the opening and closing of valves. The 3082523 Captive Washer Cap Screw is utilized to secure the follower to the cam, ensuring that the motion transfer is smooth and consistent. This secure attachment is vital for the precise timing and operation of the valve train.

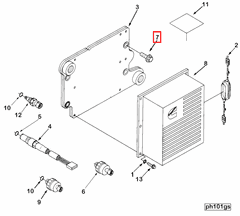

Assembly of the PDC Module

The PDC (Powertrain Control Module) is a critical component that manages various engine functions. The 3082523 Captive Washer Cap Screw is employed in the assembly of the PDC module, ensuring that all internal components are held firmly in place. This secure fastening is essential for the module’s reliable operation and durability.

Engine Control Module Attachment

The Engine Control Module (ECM) is the brain of the engine, controlling fuel injection, ignition timing, and other critical functions. The 3082523 Captive Washer Cap Screw is used to attach the ECM to its mounting bracket, ensuring it remains stable and protected from vibrations and external forces.

Ensuring Kit Component Integrity

In engine repair or upgrade kits, the 3082523 Captive Washer Cap Screw is often included to ensure that all components within the kit are properly assembled and secured. This screw helps maintain the integrity of the kit, ensuring that all parts function as intended once installed in the engine.

By understanding the role of the 3082523 Captive Washer Cap Screw in these components, engineers and mechanics can appreciate its importance in the overall performance and reliability of engine systems.

Conclusion

The 3082523 Captive Washer Cap Screw is a vital component in the assembly and maintenance of commercial trucks and Cummins engines. Its design ensures reliable fastening, simplifies the installation process, and enhances durability in demanding environments. Regular maintenance and proper installation are essential to ensure the continued performance and reliability of this Cummins part.

-

Boyce, Meherwan P. Gas Turbine Engineering Handbook, Second Edition. Gulf Professional Publishing, 2002.

↩ -

Kershaw, John F. SAE International’s Dictionary for Automotive Engineers. SAE International, 2023.

↩ -

Bennett, Sean. Modern Diesel Technology Light Duty Diesels. Cengage Learning, 2012.

↩ -

Smil, Vaclav. The History and Impact of Diesel Engines and Gas Turbines. The MIT Press, 2010.

↩ -

Cummins Inc. Owners Manual for QSL9 CM2250 L115, Bulletin Number 4388628.

↩ -

Cummins Inc. Owners Manual for QSL9 CM2250 L115, Bulletin Number 4388628.

↩ -

Cummins Inc. Owners Manual for QSL9 CM2250 L115, Bulletin Number 4388628.

↩ -

Cummins Inc. Owners Manual for QSL9 CM2250 L115, Bulletin Number 4388628.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.