This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

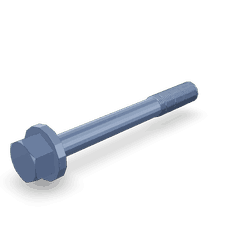

The Captive Washer Cap Screw 3079842 is a specialized fastener produced by Cummins, a renowned manufacturer in the automotive and heavy-duty truck industry. This screw is designed for use in commercial trucks, where it plays a significant role in securing various components and ensuring the structural integrity of the vehicle 1.

Basic Concepts

A Captive Washer Cap Screw is a type of fastener that includes an integrated washer, which is held in place by a protrusion on the screw’s shank. This design ensures that the washer remains attached to the screw during installation, reducing the risk of loss and simplifying the assembly process. In mechanical assemblies, these screws are used to join components securely, providing both tension and compression to maintain a tight fit 2.

Purpose and Role in Truck Operation

This Cummins part serves a specific purpose in commercial truck operations by securing critical components and contributing to the overall structural integrity of the vehicle. It is often used in applications where vibration and movement are common, ensuring that parts remain firmly attached under various operating conditions. This screw helps in maintaining the alignment and stability of truck components, which is vital for safe and efficient operation.

Key Features

The 3079842 Captive Washer Cap Screw boasts several key features that enhance its performance and durability. Its design includes an integrated washer that is securely attached to the screw, eliminating the need for separate washers during installation. The screw is made from high-quality materials, typically a durable alloy, which provides resistance to corrosion and wear. Additionally, the screw features a hexagonal head for easy tightening with standard tools, ensuring a secure and reliable fit.

Benefits

Using the 3079842 Captive Washer Cap Screw offers several advantages. The integrated washer design simplifies the installation process, reducing the likelihood of washers being misplaced or lost. This feature also ensures consistent torque application, leading to improved reliability and performance. Furthermore, the screw’s durable material composition enhances its longevity, making it a cost-effective solution for commercial truck maintenance. The ease of installation and maintenance contributes to overall efficiency in truck operations.

Installation Process

Proper installation of the 3079842 Captive Washer Cap Screw is crucial for optimal performance and longevity. Begin by ensuring the mating surfaces are clean and free of debris. Align the screw with the designated hole and use a torque wrench to tighten it to the manufacturer’s specified torque settings. This ensures that the screw is securely fastened without over-tightening, which could lead to damage. Regularly inspect the screw for signs of wear or corrosion and replace it if necessary to maintain structural integrity.

Common Applications

The 3079842 Captive Washer Cap Screw is commonly used in various components within a commercial truck. Typical applications include securing engine mounts, attaching body panels, and fastening chassis components. Its versatility makes it an important part in maintaining the structural integrity and alignment of these critical truck parts.

Troubleshooting and Maintenance

To ensure the longevity and performance of the 3079842 Captive Washer Cap Screw, regular maintenance and troubleshooting are necessary. Inspect the screw periodically for signs of corrosion, wear, or loosening. If corrosion is detected, clean the affected area and apply a suitable anti-corrosive treatment. Ensure that the screw is tightened to the correct torque specifications during installation to prevent over-tightening or under-tightening. Replace the screw if it shows significant wear or damage to maintain the integrity of the truck’s components.

Manufacturer - Cummins

Cummins is a well-established manufacturer with a strong reputation in the automotive and heavy-duty truck industry. The company has a history of innovation and commitment to quality, producing a wide range of components that meet the demanding requirements of commercial vehicles. Cummins’ dedication to research and development ensures that their products, including the 3079842 Captive Washer Cap Screw, are designed to deliver reliable performance and durability in various operating conditions.

Cummins Part 3079842 Captive Washer Cap Screw in Engine Applications

The Cummins part 3079842 Captive Washer Cap Screw is a crucial component in several of Cummins’ engine models. This part is designed to provide a secure fastening solution, ensuring that various engine components remain tightly secured during operation. Below are the engines where this part is utilized, grouped by their series for clarity.

KTA19GC CM558 and QSK19 CM500

The KTA19GC CM558 and QSK19 CM500 engines both benefit from the use of the 3079842 Captive Washer Cap Screw. These engines are part of Cummins’ QSK series, known for their reliability and efficiency in various industrial applications. The cap screw ensures that the engine’s internal components are held firmly in place, contributing to the overall durability and performance of the engine.

QSK19 CM850 MCRS and QSK50 CM2150 MCRS

The QSK19 CM850 MCRS and QSK50 CM2150 MCRS engines also incorporate the 3079842 Captive Washer Cap Screw. These engines are part of the MCRS (Modular Component Reconfigurable System) series, which is designed for flexibility and adaptability in different power generation applications. The cap screw’s role in these engines is to maintain the integrity of the modular components, ensuring that the engine operates smoothly and efficiently.

V903

The V903 engine, another Cummins model, utilizes the 3079842 Captive Washer Cap Screw. This engine is part of Cummins’ V-series, which is known for its robust design and high power output. The cap screw in this engine ensures that all critical components are securely fastened, contributing to the engine’s overall reliability and performance.

Role of Part 3079842 Captive Washer Cap Screw in Engine Systems

The Part 3079842 Captive Washer Cap Screw is instrumental in ensuring the secure and reliable assembly of various engine components. Its application spans across multiple systems, contributing to the overall functionality and durability of the engine.

Aftercooler Water Plumbing

In the aftercooler water plumbing system, the Captive Washer Cap Screw is used to fasten components that manage the flow of coolant. This ensures that connections remain tight, preventing leaks and maintaining efficient cooling of the compressed air, which is vital for engine performance.

Crankcase Breather and Arrangement

For the crankcase breather and its arrangement, the screw plays a key role in securing the breather system components. This system allows for the release of gases from the crankcase, which is essential for maintaining proper pressure levels and preventing contamination of the engine oil.

Electronic Control Module (ECM) Kit and Engine Control Module (ECM)

In the ECM kit and the engine control module, the Captive Washer Cap Screw is utilized to mount sensors and other electronic components securely. This ensures that the electrical connections are stable and that the modules are properly grounded, which is important for accurate engine management and diagnostics.

Ignition System

Within the ignition system, the screw is employed to fasten ignition coils and related components. This secure attachment is necessary for consistent spark delivery to the engine’s cylinders, ensuring reliable combustion and engine operation.

Lubricating Oil Filter

The lubricating oil filter assembly often uses the Captive Washer Cap Screw to ensure that the filter housing is tightly sealed. This is important for maintaining the integrity of the oil filtration process, which is essential for engine lubrication and longevity.

Oil Cooler SPT (Front) Mounting

For the front-mounted oil cooler, the screw is used to secure the cooler to its mounting bracket. This ensures that the cooler remains in place and operates efficiently, helping to maintain optimal engine oil temperature.

Valve Cover and Arrangement

Finally, in the valve cover and its arrangement, the Captive Washer Cap Screw is critical for sealing the valve cover to the engine block. This prevents oil leaks and ensures that the valve train components are properly lubricated and protected.

Conclusion

The 3079842 Captive Washer Cap Screw by Cummins is a vital component in the automotive and heavy-duty truck industry, ensuring the secure and reliable assembly of various engine components. Its robust design, ease of installation, and durability make it an essential part for maintaining the structural integrity and performance of commercial trucks and engines.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.