3689758

Captive Sleeve Cap Screw

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3689758 Captive Sleeve Cap Screw, manufactured by Cummins, is a specialized fastener designed for use in commercial trucks. Cummins, a leader in diesel engine technology, produces this component to meet the demanding requirements of heavy-duty applications. This screw is integral to various mechanical assemblies within commercial trucks, ensuring secure and reliable connections.

Basic Concepts

A Captive Sleeve Cap Screw is a type of fastener that includes an integrated sleeve or collar. This design allows for efficient and secure fastening, as the sleeve captures the nut or washer, preventing it from being lost during installation or operation 1. The 3689758 functions by providing a strong, tamper-resistant connection that can withstand significant stress and vibration, common in heavy-duty truck environments. Its general use in mechanical assemblies includes securing engine components, chassis parts, and other critical truck systems.

Role in Truck Operation

The 3689758 plays a significant role in the operation and maintenance of commercial trucks. It is commonly used in areas where secure fastening is crucial, such as engine mounts, transmission components, and chassis assemblies. The screw’s design ensures that connections remain intact under the harsh conditions encountered by commercial trucks, including heavy loads and rough terrain. Its application in these areas contributes to the overall reliability and safety of the vehicle 2.

Key Features

The 3689758 boasts several key features that enhance its functionality and durability. Its captive sleeve design ensures that the nut or washer remains in place, reducing the risk of loss during maintenance or operation. The screw is made from high-strength materials, providing excellent resistance to corrosion and wear. Additionally, its precise threading and robust construction allow for secure fastening, even in high-vibration environments. These design elements contribute to the screw’s longevity and reliability in demanding applications 3.

Benefits

Using the 3689758 in truck maintenance and assembly offers several advantages. The screw’s captive sleeve design simplifies installation, reducing the time and effort required for fastening. This feature also enhances reliability by ensuring that nuts or washers do not become dislodged, which can lead to loose connections and potential safety hazards. Furthermore, the screw’s high-strength materials and precise construction contribute to improved performance and durability, making it a valuable component in heavy-duty truck applications 4.

Troubleshooting and Maintenance

Common issues with the 3689758 may include corrosion, wear, or damage to the captive sleeve. Regular inspection and maintenance are crucial to ensure the screw’s longevity and optimal performance. If corrosion is detected, cleaning the affected area and applying a corrosion-resistant coating can help prevent further degradation. In cases of wear or damage, replacing the screw is recommended to maintain secure fastening. Proper torque specifications should be followed during installation to avoid over-tightening, which can lead to thread damage or component failure.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a trusted name in the automotive industry, particularly in diesel engine technology. The company is committed to innovation, quality, and customer satisfaction, providing reliable and efficient solutions for a wide range of applications, including commercial trucks, agriculture, construction, and power generation. Cummins’ expertise in engine and component design ensures that their products, like the 3689758, meet the rigorous demands of heavy-duty environments.

Captive Sleeve Cap Screw 3689758 in Cummins Engines

The Captive Sleeve Cap Screw part number 3689758 is a critical component in several Cummins engine models. This part is integral to the assembly and functionality of the engines, ensuring proper alignment and secure fastening of various engine parts.

ISX Series Engines

- ISX CM570

- ISX CM870

- ISX CM871

In the ISX series engines, the Captive Sleeve Cap Screw 3689758 is used in various applications where secure fastening is essential. This includes securing components within the engine block and ensuring the integrity of the engine’s structural components.

ISX15 Series Engines

- ISX15 CM2250

- ISX15 CM2250 SN

- ISX15 CM2350 X101

For the ISX15 series, the part 3689758 plays a vital role in maintaining the alignment and stability of the engine’s internal components. It is used in applications that require high precision and durability, ensuring that the engine operates efficiently and reliably.

QSX15 Series Engines

- QSX15 CM2250

- QSX15 CM2250 ECF

- QSX15 CM2350 X105

In the QSX15 engines, the Captive Sleeve Cap Screw 3689758 is employed in similar critical applications. It is used to fasten and secure various engine parts, ensuring that the engine maintains its structural integrity and operates smoothly under various conditions.

X15 Series Engines

- X15 CM2350 X116B

- X15 CM2350 X123B

- X15 CM2450 X134B

The X15 series engines also utilize the Captive Sleeve Cap Screw 3689758 for securing key components within the engine. This part is essential for maintaining the alignment and stability of the engine’s internal parts, contributing to the overall performance and longevity of the engine.

Role of Part 3689758 Captive Sleeve Cap Screw in Engine Systems

The part 3689758 Captive Sleeve Cap Screw is instrumental in securing various components within engine systems. Its application ensures the integrity and proper functioning of these components.

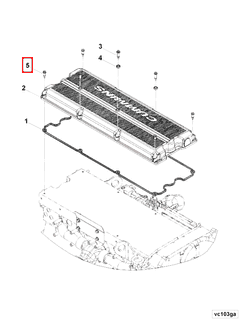

Securing the Cover

In engine systems, the cover serves as a protective barrier for internal components. The Captive Sleeve Cap Screw, part 3689758, is utilized to fasten this cover securely in place. This ensures that the cover remains tightly sealed, preventing any contaminants from entering the engine and safeguarding the internal mechanisms from external damage.

Valve Assembly Integration

Valves are essential for the regulation of air and fuel mixture within the engine. The Captive Sleeve Cap Screw plays a significant role in the valve assembly by securing valve components together. This includes fastening valve covers, which protect the valve train, and ensuring that valve adjustments are maintained accurately. The screw’s design allows for easy adjustments and maintenance, which is vital for the valve’s optimal performance.

Valve Cover Attachment

The valve cover is a critical component that encloses the valve train, consisting of camshafts, rocker arms, and other associated parts. Part 3689758 Captive Sleeve Cap Screw is employed to attach the valve cover to the engine block or cylinder head. This attachment is essential for maintaining a sealed environment around the valve train, which is necessary for preventing oil leaks and ensuring that the valve components operate within a clean and lubricated space.

By effectively utilizing part 3689758 Captive Sleeve Cap Screw in these applications, engine systems maintain their structural integrity and operational efficiency.

Conclusion

The 3689758 Captive Sleeve Cap Screw is a vital component in the maintenance and operation of commercial trucks and Cummins engines. Its design, featuring a captive sleeve, ensures secure and reliable fastening, even in demanding environments. The screw’s high-strength materials and precise construction contribute to its durability and performance, making it an essential part in heavy-duty applications. Regular maintenance and proper installation are crucial to ensure the longevity and optimal performance of this component.

-

Rendle, S., & Randall, M. (2000). Haynes Diesel Engine Systems and Data Book. Haynes Publishing.

↩ -

Bosch, R. (2007). Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive 5th Edition. Springer Vieweg.

↩ -

Quigley, J. M. (2023). SAE International’s Dictionary of Testing, Verification and Validation. SAE International.

↩ -

Hilgers, M. (2023). Entire Vehicle: Second Edition. Springer Nature.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.