3916361

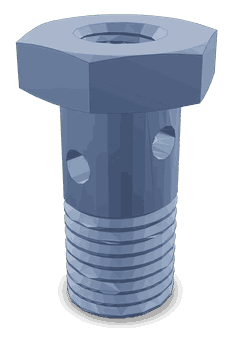

Banjo Connector Screw

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Banjo Connector Screw, part number 3916361, is a component manufactured by Cummins, a well-established name in the commercial truck industry. This part is integral to the operation of heavy-duty trucks, particularly within their hydraulic and fuel systems. Understanding its role, functionality, and proper application is key to maintaining the efficiency and reliability of these vehicles.

Basic Concepts and Functionality

A Banjo Connector Screw is a type of fitting used to connect hoses or pipes to various components within a truck’s system. Its basic design includes a threaded body and a sealing surface that interfaces with a gasket or O-ring to create a secure, leak-proof connection. This screw plays a role in the system by allowing fluid transfer between components while preventing leaks, which is vital for the operation of hydraulic and fuel systems 1.

Purpose of the 3916361 Banjo Connector Screw

The 3916361 Banjo Connector Screw is designed to facilitate the connection between hoses and fittings in fuel injection systems, hydraulic systems, and other critical areas of heavy-duty trucks. Its application ensures that fluids are transferred efficiently and securely throughout the system, contributing to the overall performance and reliability of the vehicle.

Key Features

The 3916361 Banjo Connector Screw boasts several key features that enhance its performance and durability. These include a robust material composition resistant to wear and corrosion, a specific thread type for secure fitting, and advanced sealing mechanisms to prevent leaks. Unique design elements may also be incorporated to improve the screw’s functionality in demanding environments.

Benefits

Utilizing the 3916361 Banjo Connector Screw offers several advantages. These include improved sealing capabilities, which reduce the risk of leaks and ensure efficient fluid transfer. The screw’s design also facilitates ease of installation, while its resistance to corrosion enhances its longevity. Additionally, its compatibility with various systems makes it a versatile component for heavy-duty truck maintenance and repair 2.

Installation Process

Proper installation of the 3916361 Banjo Connector Screw involves several steps to ensure a secure and leak-free connection. This process includes preparing the fitting surfaces, using the appropriate tools, and adhering to specified torque settings. Careful attention to these details during installation helps maintain the integrity of the connection and the overall system.

Troubleshooting and Maintenance

Common issues with Banjo Connector Screws can include leaks, corrosion, and wear. Regular inspection and maintenance are recommended to identify these problems early and take corrective action. This may involve cleaning the fitting surfaces, replacing gaskets or O-rings, or, in some cases, replacing the screw itself to prevent system failures.

Safety Considerations

When working with Banjo Connector Screws, it is important to follow safety practices to avoid accidents or system damage. This includes proper handling of the component, adhering to installation and maintenance procedures, and using the appropriate tools and equipment. Safety should always be a priority when performing any work on heavy-duty trucks.

Cummins: Manufacturer Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its high-quality automotive components. With a strong reputation for reliability and innovation, Cummins offers a wide range of products that play a significant role in the performance and efficiency of heavy-duty trucks. The company’s commitment to quality and customer satisfaction underscores its position in the market.

Cummins Engine Compatibility with Part 3916361

The part number 3916361, a Banjo Connector Screw, is a crucial component in the maintenance and operation of various Cummins engines. This part is designed to fit seamlessly into the engine systems, ensuring a secure connection for hydraulic or fuel lines. Below is a detailed description of how this part integrates with the specified Cummins engines.

Cummins 4B3.9 and 6B5.9 Engines

The 4B3.9 and 6B5.9 engines are part of Cummins’ range of inline-six diesel engines. The Banjo Connector Screw (part 3916361) is essential for maintaining the integrity of the fuel and hydraulic lines in these engines. Its design ensures a tight and reliable connection, preventing leaks and ensuring optimal engine performance.

Cummins 6C8.3 and B4.5 Engines

The 6C8.3 and B4.5 engines are also inline-six diesel engines, known for their robust construction and reliability. The Banjo Connector Screw (part 3916361) is integral to these engines, providing a secure fastening mechanism for various lines. This part’s precision engineering ensures that it fits perfectly, contributing to the overall efficiency and longevity of the engine.

Cummins ISB CM550 and QSB3.9 30 CM550 Engines

The ISB CM550 and QSB3.9 30 CM550 engines are part of Cummins’ QSB series, designed for heavy-duty applications. The Banjo Connector Screw (part 3916361) is a critical component in these engines, ensuring that hydraulic and fuel lines are securely connected. This part’s compatibility with these engines highlights its versatility and importance in maintaining engine integrity.

Cummins L8.9, L8.9 L121, L9.3 L105, and L9.5 L117 Engines

The L8.9, L8.9 L121, L9.3 L105, and L9.5 L117 engines are part of Cummins’ L series, known for their durability and performance. The Banjo Connector Screw (part 3916361) is essential for these engines, providing a reliable connection for various lines. Its design ensures that it fits perfectly, contributing to the overall efficiency and longevity of the engine.

Cummins QSB5.9 30 CM550 Engine

The QSB5.9 30 CM550 engine is another variant in Cummins’ QSB series, designed for heavy-duty applications. The Banjo Connector Screw (part 3916361) is a critical component in this engine, ensuring that hydraulic and fuel lines are securely connected. This part’s compatibility with this engine highlights its versatility and importance in maintaining engine integrity.

Role of Part 3916361 Banjo Connector Screw in Fuel System Components

The 3916361 Banjo Connector Screw is an essential component in various fuel system setups, ensuring secure and leak-free connections between different parts. Its application spans across multiple fuel system components, enhancing the overall efficiency and reliability of the system.

Fuel System Accessories

In fuel system accessories, the Banjo Connector Screw is often used to connect fuel lines to accessories such as fuel filters, fuel transfer pumps, and lift pumps. This ensures that the fuel flow is consistent and uninterrupted, which is vital for the proper functioning of these accessories.

Bosch Fuel Pump Kit

When integrated into a Bosch Fuel Pump Kit, the Banjo Connector Screw plays a significant role in connecting the fuel lines to the pump. This connection is essential for maintaining the integrity of the fuel supply, ensuring that the pump receives a steady flow of fuel to operate efficiently.

Fuel Filter and Fuel Transfer Pump

The Banjo Connector Screw is frequently employed in the plumbing of fuel filters and fuel transfer pumps. By providing a secure connection between the fuel lines and these components, it helps prevent fuel leaks and maintains the pressure required for optimal performance.

Engine Mounting and Drain Location

In scenarios where fuel lines need to be routed around engine mounting points or near drain locations, the Banjo Connector Screw ensures that these connections remain tight and secure. This is particularly important in high-vibration environments where loose connections can lead to fuel leaks or system failures.

Plumbing and Fuel Lines

The Banjo Connector Screw is a staple in the plumbing of fuel lines throughout the system. Whether connecting the fuel lines to the fuel tank, engine, or various fuel system components, its role in maintaining a leak-free connection is indispensable. This is especially true in complex fuel systems where multiple connections are necessary.

Accessory and Fuel System Integration

For accessories such as fuel system accessories and fuel transfer pumps, the Banjo Connector Screw ensures that all components are seamlessly integrated. This integration is key to maintaining the overall efficiency of the fuel system, allowing for smooth operation and reliable performance.

Lift Pump and Fuel Supply

In systems utilizing a lift pump, the Banjo Connector Screw is used to connect the fuel lines to the pump, ensuring a consistent fuel supply to the engine. This connection is vital for maintaining the pressure and flow rate required for the engine to operate under various conditions.

Fuel System Reliability

Overall, the 3916361 Banjo Connector Screw contributes to the reliability of the fuel system by providing secure, leak-free connections across various components. Its application in fuel filters, fuel transfer pumps, Bosch fuel pump kits, and other fuel system accessories underscores its importance in maintaining the integrity and efficiency of the fuel supply system.

Conclusion

The 3916361 Banjo Connector Screw is a critical component in the maintenance and operation of heavy-duty trucks, particularly within their hydraulic and fuel systems. Its robust design, resistance to corrosion, and advanced sealing mechanisms make it a reliable choice for ensuring secure and leak-free connections. Proper installation, regular maintenance, and adherence to safety practices are essential for maximizing the performance and longevity of this Cummins part. Its compatibility with various Cummins engines and fuel system components further highlights its versatility and importance in the commercial truck industry.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.