3905307

Banjo Connector Screw

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

Minimum Quantity 2

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3905307 Banjo Connector Screw, manufactured by Cummins, is a critical component in the fluid systems of commercial trucks. This part is designed to facilitate the secure connection of hoses and pipes, ensuring the efficient transfer of fluids such as fuel, oil, and hydraulic fluid. Understanding its function and integration within a truck’s system is vital for maintaining the vehicle’s performance and reliability 1.

Basic Concepts of Banjo Connector Screws

A banjo connector screw is a fitting used in fluid systems to connect hoses or pipes to various components. It typically consists of a bolt, a banjo fitting, and washers. The banjo fitting is a small, usually U-shaped piece that allows for the connection of hoses at an angle, providing flexibility in routing and installation. The bolt secures the fitting in place, while the washers ensure a tight seal, preventing leaks. The operation of a banjo connector screw involves threading the bolt into a tapped hole, positioning the banjo fitting over the hose end, and tightening to create a secure connection 2.

Role of the 3905307 Banjo Connector Screw in Truck Operation

The 3905307 Banjo Connector Screw plays a crucial role in the fluid systems of commercial trucks by providing a reliable connection point for hoses and pipes. It ensures that fluids are transferred efficiently throughout the system, contributing to the overall functionality and efficiency of the vehicle. By maintaining secure connections, it helps prevent leaks and ensures that the system operates under the correct pressure, which is crucial for the performance of engines, transmissions, and hydraulic systems 3.

Key Features

The 3905307 Banjo Connector Screw is characterized by several key features that enhance its performance and durability. It is typically made from high-strength materials such as stainless steel, which provides resistance to corrosion and wear. The design includes precision-machined threads and a robust banjo fitting, ensuring a secure and leak-proof connection. Additionally, the screw may feature specialized washers that improve sealing capabilities, further contributing to its reliability in demanding applications 4.

Benefits

Using the 3905307 Banjo Connector Screw offers several advantages. Its high-quality material composition and precise manufacturing ensure improved sealing, reducing the risk of leaks in the fluid system. The design of the screw allows for ease of installation, enabling quick and efficient connections during maintenance or repairs. Furthermore, its resistance to wear and corrosion enhances the longevity of the component, providing reliable performance over time 1.

Troubleshooting and Maintenance

Common issues with banjo connector screws may include leaks, corrosion, or difficulty in tightening. Troubleshooting these problems involves inspecting the fitting and connections for signs of wear or damage, ensuring that washers are in good condition, and verifying that the screw is properly tightened. Regular maintenance, such as cleaning the fitting and replacing worn washers, can help ensure the longevity and reliable performance of the banjo connector screw. It is also important to use the correct torque specifications when tightening to avoid over-tightening, which can damage the fitting, or under-tightening, which can lead to leaks 2.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for its commitment to quality and innovation. The company offers a wide range of products designed to meet the demanding requirements of commercial vehicles, ensuring reliable performance and efficiency. Cummins’ dedication to excellence in manufacturing is evident in its automotive components, which are engineered to deliver superior performance and durability 3.

Cummins Engine Compatibility with Part 3905307

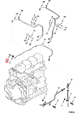

The Banjo Connector Screw, part number 3905307, manufactured by Cummins, is a critical component in the engine systems of several Cummins engines. This part is designed to securely attach and seal the banjo connectors, ensuring that fluid lines remain tightly connected to the engine’s hydraulic or fuel systems.

Cummins 4B3.9 and QSB3.9 30 CM550 Engines

The part 3905307 is compatible with the Cummins 4B3.9 and QSB3.9 30 CM550 engines. These engines are known for their reliability and efficiency, often used in various applications such as agricultural machinery and construction equipment. The banjo connector screw ensures that the fluid lines remain securely attached, preventing leaks and maintaining system integrity 4.

Cummins 6B5.9 and QSB5.9 30 CM550 Engines

Similarly, the 6B5.9 and QSB5.9 30 CM550 engines also utilize the 3905307 banjo connector screw. These engines are typically found in medium-duty applications, providing robust performance and durability. The screw’s role in these engines is to maintain the connection between the banjo fittings and the engine’s hydraulic or fuel lines, ensuring smooth operation and preventing any potential fluid loss 1.

Cummins B4.5, B6.7S, and QSB5.9 CM550 Engines

The part 3905307 is also suitable for the Cummins B4.5, B6.7S, and QSB5.9 CM550 engines. These engines are often used in heavy-duty applications, requiring components that can withstand high pressures and demanding conditions. The banjo connector screw in these engines ensures that the fluid lines are securely fastened, which is crucial for maintaining the engine’s performance and longevity 2.

By ensuring a tight and reliable connection, the 3905307 banjo connector screw plays a vital role in the overall functionality and safety of these Cummins engines.

Role of Part 3905307 Banjo Connector Screw in Engine Systems

The 3905307 Banjo Connector Screw is an essential component in various engine systems, facilitating secure and efficient connections between different parts. Its primary function is to ensure a leak-free and robust connection in fuel and injector plumbing systems.

In the fuel plumbing system, the Banjo Connector Screw plays a significant role by connecting the fuel pump to the fuel injectors. This connection is vital for maintaining the integrity of the fuel line, ensuring that fuel is delivered efficiently without any leaks.

When integrated with the Bosch injection pump, the Banjo Connector Screw helps in securing the fuel lines to the pump, contributing to the overall efficiency and reliability of the fuel delivery system.

In systems utilizing an air heater starting aid, the Banjo Connector Screw is used to connect the fuel lines to the starting aid, ensuring that the fuel is properly delivered to aid in engine start-up under cold conditions.

For the base fuel pump and fuel pump coupling, the Banjo Connector Screw ensures a secure connection between the pump and the fuel lines, which is essential for consistent fuel pressure and flow.

In fuel pump plumbing and injector plumbing, the Banjo Connector Screw is utilized to connect various components, such as the lower engine gasket set and pump fuel, ensuring that the fuel system remains sealed and operates efficiently.

Additionally, in kit fuel pump conv and kit ve conversion systems, the Banjo Connector Screw is employed to connect the converted fuel pump to the existing fuel lines, facilitating a smooth transition and integration of new components into the engine system.

Overall, the 3905307 Banjo Connector Screw is a fundamental component in ensuring the secure and efficient operation of fuel and injector plumbing within various engine systems 3.

Conclusion

The 3905307 Banjo Connector Screw is a vital component in the fluid systems of commercial trucks and Cummins engines. Its design and features ensure secure and efficient connections, contributing to the overall performance and reliability of the vehicle. Regular maintenance and proper installation are essential to maximize the benefits of this Cummins part, ensuring long-term durability and efficiency in demanding applications 4.

-

Heavy Duty Truck Systems Fifth Edition, Sean Bennett, Ian Andrew Norman, Delmar Cengage Learning, 2011

↩ ↩ ↩ -

Understanding Automotive Electronics, William B. Ribbens, Elsevier Science, 2003

↩ ↩ ↩ -

Road and Off-Road Vehicle Dynamics, Moustafa ElGindy and Zeinab ElSayegh, Springer Nature, 2023

↩ ↩ ↩ -

Automotive Maintenance: Light Repair, Rob Thompson, Cengage Learning, 2019

↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.