4990915

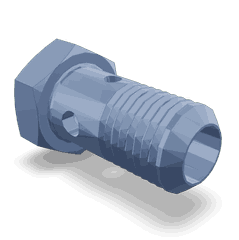

Banjo Connector Screw

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 4990915 Banjo Connector Screw, manufactured by Cummins, is a component designed for use in heavy-duty truck systems. Its primary role is within fluid transfer systems, where it facilitates the secure and efficient transfer of fluids such as hydraulic oil, fuel, or lubrication oil. Cummins, a well-established name in the automotive and heavy-duty truck industry, produces this component with a focus on reliability and performance 1.

Function and Operation

The Banjo Connector Screw operates by connecting two points in a truck’s hydraulic or fuel system, allowing for fluid transfer while maintaining system integrity. It features a unique design that includes a bolt and a banjo fitting, which together create a sealed connection. This mechanism ensures that fluids are transferred without leaks, contributing to the efficient operation of the system. The screw’s design also allows for easy connection and disconnection, facilitating maintenance and repair processes 2.

Key Features

This Cummins part is constructed from high-quality materials, ensuring durability and resistance to wear and corrosion. Its design includes features that enhance performance, such as a precise thread pitch for secure fastening and a robust banjo fitting that can withstand high pressure. These attributes not only differentiate it from other similar components but also contribute to its reliable operation in demanding environments 3.

Role in Truck Systems

In the operation of a truck, the Banjo Connector Screw plays a role in integrating into hydraulic, fuel, or lubrication systems. By providing a secure connection point for fluid transfer, it contributes to the overall efficiency and reliability of these systems. Its presence ensures that fluids are delivered where needed without interruption, supporting the truck’s performance and longevity 4.

Benefits

Utilizing the 4990915 offers several advantages. These include improved system performance due to its secure and leak-free connections, enhanced durability thanks to its high-quality material composition, and potential cost savings over time as a result of its reliable design, which reduces the need for frequent replacements or repairs.

Installation and Maintenance

Proper installation of the Banjo Connector Screw is key to ensuring optimal performance. It should be tightened to the manufacturer’s specified torque to achieve a secure seal without overtightening, which could damage the fitting. Routine maintenance checks should include inspecting the connection for signs of wear or leaks and ensuring that all components are securely fastened. Following these guidelines can prolong the component’s lifespan and ensure continued reliable operation.

Troubleshooting Common Issues

Common problems associated with Banjo Connector Screws may include leaks or connection failures. To troubleshoot these issues, first, ensure that the screw is properly installed and tightened to the correct torque. If leaks persist, inspect the banjo fitting and the connected hose or pipe for damage. In some cases, replacement or repair of the fitting may be necessary to resolve the issue.

Cummins: Manufacturer Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the heavy-duty truck industry. The company’s commitment to excellence is evident in its wide range of products, including the 4990915, which embodies Cummins’ dedication to providing reliable and high-performance components for the automotive sector.

Cummins Engine Compatibility with Part 4990915

The Banjo Connector Screw, part number 4990915, manufactured by Cummins, is a component in the fuel and hydraulic systems of various Cummins engines. This part ensures a secure and leak-free connection for fuel lines, hydraulic lines, and other fluid lines. Below is a detailed look at how this part fits with the specified engines.

B3.3 and QSB3.3 CM2150 Engines

The B3.3 and QSB3.3 CM2150 engines utilize the Banjo Connector Screw in their fuel and hydraulic systems. This part is for maintaining the integrity of the connections in these smaller, yet robust engines, ensuring efficient operation and reliability.

B6.7 CM2350 B135B and QSB6.7 CM2350 B105 Engines

Both the B6.7 CM2350 B135B and QSB6.7 CM2350 B105 engines incorporate the Banjo Connector Screw in their systems. These engines, known for their balance of power and efficiency, rely on this part to secure various fluid lines, ensuring that the connections remain tight and leak-proof under operational stresses.

ISB4.5 CM2350 B104 and ISB5.9 CM2880 B110 Engines

The ISB4.5 CM2350 B104 and ISB5.9 CM2880 B110 engines also use the Banjo Connector Screw. These engines, designed for heavy-duty applications, benefit from the reliability of this part in maintaining secure connections in their fuel and hydraulic systems, contributing to the overall performance and longevity of the engines.

QSB5.9 CM2880 B115 Engine

The QSB5.9 CM2880 B115 engine incorporates the Banjo Connector Screw in its systems. This part is crucial for ensuring that the connections in the engine’s fuel and hydraulic lines remain secure, supporting the engine’s performance in demanding applications.

By ensuring a tight and leak-free connection, the 4990915 plays a role in the functionality and reliability of these Cummins engines.

Role of Part 4990915 Banjo Connector Screw in Engine Systems

The 4990915 is a component in various engine systems, facilitating secure and leak-proof connections in critical plumbing and fitting applications. Its primary function is to ensure the integrity of fluid pathways, which is vital for the efficient operation of the engine.

Fuel System Integration

In the fuel system, the 4990915 is employed in the fuel inlet and fuel filter plumbing. It creates a robust connection between the fuel lines and the fuel filter, ensuring that fuel is delivered consistently and without leaks. This component is also used in the main fuel plumbing, connecting the fuel pump to the injectors, thereby maintaining the precise fuel delivery required for optimal engine performance.

Cooling System Applications

For the engine coolant system, the 4990915 plays a significant role in both the primary and auxiliary cooling circuits. It is utilized in the auxiliary cooling plumbing to connect additional cooling lines, such as those for the transmission or aftercooler. In the main engine coolant plumbing, it ensures secure connections between the radiator, water pump, and engine block, helping to maintain consistent coolant flow and temperature regulation.

Turbocharger and Vent Systems

In turbocharged engines, the 4990915 is integral to the turbocharger plumbing. It is used in the connections for the turbocharger coolant lines, ensuring that the turbocharger receives adequate cooling to prevent overheating and maintain efficiency. Additionally, it is employed in the turbocharger kit plumbing to connect various components, such as the intercooler and charge air cooler.

The component is also vital in the vent system, where it secures connections in the crankcase ventilation system. This helps manage pressure within the engine, preventing oil leaks and ensuring that harmful gases are properly routed away from the engine compartment.

Cabin Comfort Systems

Beyond the engine’s core systems, the 4990915 is used in the cabin heater plumbing. It ensures that the heater core receives a consistent flow of hot coolant from the engine, providing reliable cabin heating for occupant comfort.

Conclusion

In summary, the 4990915 Banjo Connector Screw is a versatile and reliable component that enhances the functionality and safety of various engine systems by ensuring secure and leak-free connections.

-

Martyr, A.J. Engine Testing: Theory and Practice: Third Edition. SAE International, 2007.

↩ -

Aird, Forbes. Bosch Fuel Injection Systems. HP Books, 2001.

↩ -

Harrison, Matthew. Controlling Noise and Vibration in Road Vehicles. SAE International, 2004.

↩ -

Sully, F. K. Motor Vehicle Mechanics Textbook, Fifth Edition. Heinemann Professional Publishing, 1998.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.