This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

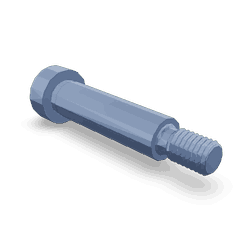

The 4308123 Shoulder Cap Screw, manufactured by Cummins, is a crucial component in the commercial truck industry, contributing to the reliability and efficiency of truck operations.

Basic Concepts of Shoulder Cap Screws

A shoulder cap screw is a fastener with a cylindrical section under the head, known as the “shoulder.” This design ensures a precise fit in corresponding holes, providing secure fastening and alignment in mechanical assemblies. These screws are commonly used in applications requiring both strength and alignment, such as engine components and transmission systems 1.

Purpose of the 4308123 Shoulder Cap Screw in Truck Operations

This Cummins part plays a role in the operation and maintenance of commercial trucks by securing various components within the engine and transmission systems. Its applications include fastening engine parts, securing transmission components, and other areas where a robust and precise fit is necessary. This screw ensures that parts remain securely in place, contributing to the overall performance and longevity of the truck 2.

Key Features of the 4308123 Shoulder Cap Screw

The 4308123 Shoulder Cap Screw is designed with specific features that make it suitable for heavy-duty applications. It has a particular thread type that provides strong fastening capabilities, a shoulder diameter that ensures a precise fit, and is made from a material grade that offers durability and resistance to various stresses. These design elements contribute to its effectiveness in demanding environments 3.

Benefits of Using the 4308123 Shoulder Cap Screw

Using this part offers several advantages. Its design enhances durability, allowing it to withstand the rigors of heavy-duty truck operations. It also provides resistance to shear and tensile stresses, ensuring that it remains secure under load. Additionally, its performance in high-stress environments contributes to the reliability and efficiency of truck operations 4.

Installation Guidelines

Proper installation of the 4308123 Shoulder Cap Screw is vital for optimal performance and longevity. It should be installed using the correct tools to avoid damage. The screw should be tightened to the specified torque to ensure a secure fit without over-tightening, which could lead to stripping or damage. Following these guidelines helps maintain the integrity of the fastening and the components it secures 5.

Troubleshooting Common Issues

Common issues with shoulder cap screws include loosening, corrosion, or damage. Loosening can often be addressed by re-tightening the screw to the correct torque. Corrosion may require cleaning and possibly the application of a protective coating. Damage to the screw or the corresponding hole may necessitate replacement. Identifying the issue early and applying the appropriate solution helps maintain the effectiveness of the fastening 6.

Maintenance Tips

Maintaining the 4308123 Shoulder Cap Screw involves regular inspection to check for signs of wear, corrosion, or loosening. Torque specifications should be followed during installation and periodic checks to ensure the screw remains securely fastened. Knowing when to consider replacement, based on signs of wear or damage, helps prevent failures and ensures continued reliable operation 7.

Cummins: A Brief Overview

Cummins Inc. is a leader in the commercial truck industry, known for its commitment to quality and innovation. With a broad product range that includes engines, transmissions, and aftermarket parts, Cummins has established a reputation for reliability and performance. The company’s history of excellence and dedication to advancing technology makes it a trusted partner in the trucking industry 8.

Compatibility of 4308123 with Engine Models

The 4308123 Shoulder Cap Screw is compatible with several Cummins engine models, including the VTA903, CM2250, and V105 engines. This compatibility allows for streamlined maintenance and repair processes, as technicians can use the same screw for multiple engine types, reducing inventory needs and simplifying part management 9.

Role of 4308123 in Engine Systems

This part is instrumental in ensuring the secure and efficient operation of various engine components. In mounting systems, it plays a significant role in attaching and stabilizing components to the engine block or other structural elements. Its design allows for a firm grip, minimizing the risk of loosening under vibration or thermal expansion, which is common in engine environments.

When it comes to the alternator, the 4308123 Shoulder Cap Screw is used to secure the alternator to its mounting bracket. This ensures that the alternator remains in the correct position and orientation, which is essential for its efficient operation. Proper mounting of the alternator is vital for maintaining the correct belt tension, which in turn ensures optimal performance of the alternator in generating and supplying electrical power to the engine’s electrical systems 10.

Conclusion

The 4308123 Shoulder Cap Screw is a vital component in the commercial truck industry, offering secure fastening and alignment in various engine and transmission applications. Its design features, including a specific thread type, shoulder diameter, and durable material grade, make it suitable for heavy-duty applications. Proper installation, maintenance, and troubleshooting are essential to ensure the longevity and reliability of this part in truck operations.

-

Giles, T. (2019). Automotive Engines Diagnosis Repair and Rebuilding. Cengage Learning.

↩ -

Fijalkowski, B.T. (2011). Automotive Mechatronics Operational and Practical Issues Volume 1. Springer.

↩ -

SAE International. (2013). Composite Materials Handbook Volume 4 Metal Matrix Composites. SAE International.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 5659811.

↩ -

Giles, T. (2019). Automotive Engines Diagnosis Repair and Rebuilding. Cengage Learning.

↩ -

Fijalkowski, B.T. (2011). Automotive Mechatronics Operational and Practical Issues Volume 1. Springer.

↩ -

SAE International. (2013). Composite Materials Handbook Volume 4 Metal Matrix Composites. SAE International.

↩ -

Cummins Inc. (n.d.). Company Overview. Retrieved from Cummins Official Website.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 5659811.

↩ -

Giles, T. (2019). Automotive Engines Diagnosis Repair and Rebuilding. Cengage Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.