4067806

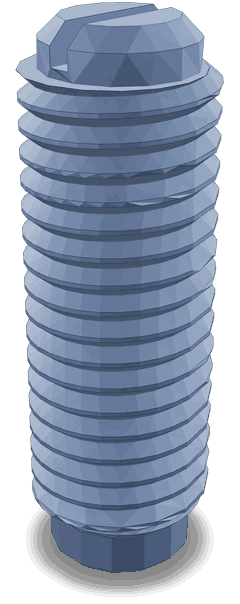

Crosshead Adjusting Screw

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Crosshead Adjusting Screw, identified by part number 4067806, is a component manufactured by Cummins, a well-established name in the automotive industry. This screw is integral to the operation of heavy-duty truck engines, ensuring optimal performance and longevity. Cummins is renowned for its commitment to quality and innovation in engine components, and the Crosshead Adjusting Screw is a testament to this dedication 1.

Function and Operation

The Crosshead Adjusting Screw operates within the engine to maintain proper alignment and clearance between the crosshead and the crankshaft. This alignment is vital for the smooth operation of the engine, as it ensures that the connecting rod moves efficiently without undue stress or friction. By maintaining the correct clearance, the screw contributes to the overall performance and durability of the engine, allowing it to operate under heavy loads with minimal wear 2.

Purpose of the Crosshead Adjusting Screw

The specific role of the Crosshead Adjusting Screw in a truck engine is to facilitate precise adjustments to the crosshead’s position relative to the crankshaft. This adjustment is crucial for engine efficiency and reliability, as it allows for fine-tuning of the engine’s components to ensure they work in harmony. Proper alignment and clearance reduce the risk of mechanical failure and enhance the engine’s operational lifespan 3.

Key Features

The Crosshead Adjusting Screw is designed with several features that enhance its functionality and durability. It is typically made from high-strength materials to withstand the rigors of heavy-duty engine operation. The screw’s design allows for easy adjustment, ensuring that technicians can make precise modifications to the crosshead’s position. Additionally, the screw is engineered to resist wear and corrosion, contributing to its longevity in demanding environments 4.

Benefits

The advantages provided by the Crosshead Adjusting Screw include improved engine performance, reduced wear on connecting components, and simplified maintenance procedures. By ensuring proper alignment and clearance, the screw helps to optimize the engine’s efficiency and reduce the likelihood of mechanical issues. Additionally, the ease of adjustment allows for quicker maintenance, minimizing downtime and enhancing the overall reliability of the engine.

Installation Process

Installing the Crosshead Adjusting Screw requires careful attention to detail to ensure correct fitting and operation. The process involves aligning the screw with the crosshead and crankshaft, making precise adjustments to achieve the desired clearance. Technicians may use specialized tools to facilitate this process, ensuring that the screw is securely fastened and properly positioned. Following the manufacturer’s guidelines for installation is crucial to avoid potential issues.

Troubleshooting Common Issues

Typical problems associated with the Crosshead Adjusting Screw include misalignment and wear. Misalignment can lead to increased friction and wear on connecting components, while wear on the screw itself can compromise its effectiveness. Diagnosing these issues involves inspecting the screw and crosshead for signs of damage or improper alignment. Resolution may require readjustment of the screw or, in severe cases, replacement of the component.

Maintenance Tips

Regular maintenance practices are essential to ensure the longevity and optimal performance of the Crosshead Adjusting Screw. This includes periodic inspection of the screw and crosshead for signs of wear or misalignment. Cleaning the screw and surrounding components can prevent the buildup of debris that may affect its operation. Adhering to recommended inspection intervals and performing routine checks can help identify potential issues before they lead to significant problems.

Cummins: A Brief Overview

Cummins Inc. is a global leader in the design, manufacture, and distribution of engines and related technologies. With a history spanning over a century, Cummins has built a reputation for quality, innovation, and reliability in the automotive industry. The company offers a wide range of products, including engines, filtration systems, and power generation equipment, serving various markets such as transportation, construction, and agriculture. Cummins’ commitment to excellence is evident in its engine components, like the Crosshead Adjusting Screw, which are designed to meet the demanding requirements of heavy-duty applications.

Crosshead Adjusting Screw (Part 4067806) Compatibility with Cummins Engines

The Crosshead Adjusting Screw, part number 4067806, manufactured by Cummins, is a critical component in the operation of certain Cummins engines. This part is integral to the engine’s functionality, ensuring precise adjustments and optimal performance. Below is a detailed description of its compatibility with specific Cummins engines.

QST30 CM2350 T101 and QST30 CM552 Engines

The Crosshead Adjusting Screw (4067806) is designed to fit seamlessly within the QST30 CM2350 T101 and QST30 CM552 engines. These engines are part of Cummins’ robust lineup, known for their reliability and efficiency in various applications. The screw’s role in these engines is to maintain the correct clearance between the crosshead and the cylinder wall, which is crucial for preventing wear and ensuring smooth operation.

In the QST30 CM2350 T101 engine, the Crosshead Adjusting Screw is used to fine-tune the clearance between the crosshead and the cylinder wall. This adjustment is vital for maintaining the engine’s performance and longevity. Similarly, in the QST30 CM552 engine, the screw performs the same function, ensuring that the crosshead operates within the specified parameters.

The design of the Crosshead Adjusting Screw allows it to be easily integrated into both engines, providing a reliable method for making necessary adjustments. This compatibility ensures that technicians and engineers can maintain and service these engines with confidence, knowing that the part is specifically engineered to fit and function correctly within these models.

Conclusion

The Crosshead Adjusting Screw (part number 4067806) by Cummins is a vital component in the operation of heavy-duty truck engines. Its role in maintaining proper alignment and clearance between the crosshead and crankshaft ensures optimal engine performance and longevity. The screw’s design, made from high-strength materials and engineered to resist wear and corrosion, contributes to its durability in demanding environments. Regular maintenance and proper installation are crucial to maximizing the benefits of this component, ensuring that engines operate efficiently and reliably.

-

Ling, Frederick F. The Automotive Body. Springer Science, 2011.

↩ -

Asef, Pedram, Sanjeevikumar Padmanaban, and Andrew Lapthorn. Modern Automotive Electrical Systems. Wiley, 2022.

↩ -

Reif, Konrad. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩ -

Eret, Angelina. Dynamic and Fatigue Assessment of Heavy-Duty Engine Valves. Springer Nature, 2024.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.