4060469

Socket Head Cap Screw

Cummins®

AVAILABLE

1 is currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Socket Head Cap Screw, specifically part number 4060469 by Cummins, is a vital component in the maintenance and operation of commercial trucks. Cummins Inc., a renowned manufacturer in the commercial truck industry, produces this screw, which is integral to ensuring the reliability and efficiency of truck components. This overview will delve into the design, function, and applications of the 4060469 Socket Head Cap Screw, highlighting its role in truck maintenance and operation.

Basic Concepts of Socket Head Cap Screws

A Socket Head Cap Screw is a type of fastener characterized by its cap head and hexagonal socket. This design allows for efficient tightening and loosening using a hex key, making it a popular choice in various fastening applications. The cap head provides a larger surface area for distribution of clamping force, while the hexagonal socket ensures precise and secure fastening 1.

Role of the 4060469 Socket Head Cap Screw in Truck Operation

The 4060469 Socket Head Cap Screw plays a significant role in the operation of commercial trucks. It is utilized in various truck components and systems, including engine mounts, chassis assemblies, and other critical areas where secure fastening is required. Its design ensures that it can withstand the rigors of heavy-duty applications, contributing to the overall reliability and performance of the truck 2.

Key Features of the 4060469 Socket Head Cap Screw

The 4060469 Socket Head Cap Screw is distinguished by several design elements and material properties. Its hexagonal socket allows for easy engagement with hex keys, facilitating quick and efficient installation. The cap head design distributes clamping force effectively, reducing the risk of damage to connected components. Additionally, the screw is made from high-quality materials that offer excellent resistance to corrosion and wear, ensuring durability in demanding environments 3.

Benefits of Using Socket Head Cap Screws

Socket Head Cap Screws, including the 4060469, offer several advantages. The hexagonal socket design allows for high torque application, making it suitable for applications requiring strong fastening. Additionally, the cap head design reduces the likelihood of the screw loosening over time, enhancing the security of the fastening. The ease of use with hex keys also contributes to efficient installation and maintenance processes.

Installation and Usage Guidelines

Proper installation of the 4060469 Socket Head Cap Screw is crucial for ensuring its effectiveness and longevity. It is recommended to use the appropriate hex key for tightening, ensuring that the screw is engaged properly within the socket. Torque specifications should be followed to avoid over-tightening, which can lead to damage, or under-tightening, which can compromise the fastening. Using the correct tools and following manufacturer guidelines will ensure optimal performance.

Maintenance and Troubleshooting

To maintain the performance and longevity of Socket Head Cap Screws, regular inspection and maintenance are recommended. This includes checking for signs of corrosion, wear, or loosening. If issues are detected, such as corrosion or damage to the screw, replacement may be necessary to ensure continued reliability. Troubleshooting common issues, such as loosening screws, may involve re-tightening to the specified torque or investigating potential causes of excessive vibration or movement.

Safety Considerations

When working with Socket Head Cap Screws, it is important to observe safety practices to prevent injury and ensure effective fastening. This includes using the correct tools for installation and maintenance, wearing appropriate personal protective equipment, and following manufacturer guidelines for torque specifications and handling procedures. Proper tool usage and careful handling will contribute to safe and effective work practices.

Cummins: A Brief Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its commitment to quality and innovation. With a rich history of producing reliable and high-performance components, Cummins serves a wide range of industries with its diverse product offerings. The company’s dedication to excellence is evident in its products, including the 4060469 Socket Head Cap Screw, which exemplifies Cummins’ standards for quality and durability in commercial truck applications.

Socket Head Cap Screw 4060469 in Cummins Engines

The Socket Head Cap Screw 4060469, manufactured by Cummins, plays a crucial role in the assembly and maintenance of several Cummins engine models. This part is integral to the structural integrity and operational efficiency of the engines, ensuring that components remain securely fastened.

ISX CM570 and M11 CELECT PLUS

In the ISX CM570 and M11 CELECT PLUS engines, the Socket Head Cap Screw 4060469 is utilized in various critical applications. These engines, known for their advanced technology and performance, require precise fastening to maintain their complex systems. The screw is often used in areas where high torque and vibration resistance are essential, such as securing engine covers, mounting brackets, and other structural components.

M11 MECHANICAL

The M11 MECHANICAL engine also benefits from the Socket Head Cap Screw 4060469. This engine, while less technologically advanced than the CM570 and CELECT PLUS variants, still relies on robust and reliable fasteners to ensure longevity and performance. The screw is employed in similar applications, ensuring that all parts are tightly and securely fastened, which is vital for the engine’s operational safety and efficiency.

Common Applications

Across these engines, the Socket Head Cap Screw 4060469 is typically used in the following areas:

- Engine Cover Fastening: Ensuring the engine cover remains securely attached to prevent leaks and maintain internal pressure.

- Mounting Brackets: Securing various brackets that hold engine components in place, reducing the risk of misalignment and mechanical failure.

- Component Assembly: Used in the assembly of different engine parts, providing the necessary strength and stability to withstand operational stresses.

By using the Socket Head Cap Screw 4060469, Cummins ensures that their engines maintain high standards of reliability and performance, making this part a critical component in the overall design and functionality of the ISX CM570, M11 CELECT PLUS, and M11 MECHANICAL engines.

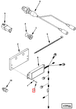

Role of Part 4060469 Socket Head Cap Screw in Engine Systems

In the intricate assembly of engine systems, the part 4060469 Socket Head Cap Screw serves as a fundamental fastening component, ensuring the secure attachment of various critical modules and components.

Electronic Control Module Kit

Within the electronic control module kit, the Socket Head Cap Screw is employed to fasten the control module to its designated mounting location. This secure attachment is essential for maintaining the module’s position and ensuring reliable electrical connections.

Fuel Control Module

The fuel control module, which regulates the fuel supply to the engine, relies on the Socket Head Cap Screw to secure it in place. This fastening is vital for the module’s stability and accurate fuel delivery.

Fuel Pump and Interface

In the fuel pump assembly, the Socket Head Cap Screw is used to attach the pump to its housing and secure the interface components. This ensures the pump operates within its designed parameters, contributing to efficient fuel delivery.

Step Time Control

For step time control mechanisms, the Socket Head Cap Screw plays a role in securing components that regulate the timing of fuel injection. Accurate timing is essential for optimal engine performance and efficiency.

Primer and Fuel System

In the priming pump and broader fuel system, the Socket Head Cap Screw is utilized to secure components that facilitate the priming process. This ensures that the fuel system is adequately pressurized before engine start-up, enhancing reliability.

Pump and Fuel Components

Across various pump and fuel components, the Socket Head Cap Screw is a common fastening solution. Its use ensures that these components remain securely in place, contributing to the overall stability and functionality of the fuel system.

The Socket Head Cap Screw, part 4060469, is a versatile and essential component in the assembly and maintenance of engine systems, facilitating the secure attachment of a wide range of modules and components.

Conclusion

The 4060469 Socket Head Cap Screw by Cummins is a critical component in the maintenance and operation of commercial trucks and engines. Its design, featuring a cap head and hexagonal socket, allows for efficient and secure fastening, making it suitable for heavy-duty applications. The screw’s high-quality materials ensure resistance to corrosion and wear, contributing to the durability and reliability of truck and engine components. Proper installation, maintenance, and adherence to safety practices are essential for maximizing the performance and longevity of this part. Cummins’ commitment to quality and innovation is reflected in the 4060469 Socket Head Cap Screw, which plays a vital role in the structural integrity and operational efficiency of their engines.

-

Randall, Martynn. Haynes Manual on Diesel Engines. Haynes Publishing, 2015.

↩ -

Schneider, Wolf-Henning. Pistons and Engine Testing. Springer Nature, 2016.

↩ -

Brown Jr, Andrew. Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles. National Academy of Sciences, 2010.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.