4058673

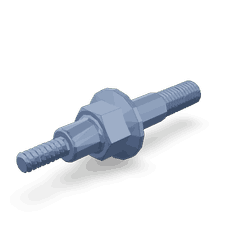

Studded Flange Cap Screw

Cummins®

AVAILABLE

4 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Studded Flange Cap Screw, identified by Part #4058673, is a component manufactured by Cummins, a well-established name in the automotive industry. This screw is integral to the mechanical systems of heavy-duty trucks, ensuring secure fastening and reliable performance under demanding conditions.

Basic Concepts

A Studded Flange Cap Screw is a type of fastener that includes a threaded stud with a flange at one end and is designed to be used with a nut. The flange provides a larger surface area for distribution of clamping force, which enhances the screw’s ability to hold components securely in place. Within a truck’s mechanical system, these screws are used to fasten various parts, ensuring they remain securely attached despite vibrations and other stresses encountered during operation 1.

Purpose and Role

The Studded Flange Cap Screw plays a significant role in the operation of a truck by providing a secure connection between components. It is commonly used in applications where high tensile strength and resistance to vibration are required. This includes fastening engine components, transmission parts, and other critical assemblies. Its role is vital in maintaining the integrity and functionality of these systems 2.

Key Features

The Studded Flange Cap Screw is characterized by several key features that enhance its performance. It is typically made from high-strength materials such as alloy steel, which provides durability and resistance to wear. The design includes a flange that distributes clamping force more evenly, reducing the risk of component deformation. Additionally, the screw’s threaded stud allows for easy installation and removal using standard tools 3.

Benefits

Using a Studded Flange Cap Screw offers several advantages in truck maintenance and operation. Its high tensile strength ensures that components remain securely fastened, even under extreme conditions. The flange design enhances the distribution of clamping force, which can prolong the life of both the screw and the components it secures. Furthermore, the ease of installation and removal facilitates quicker maintenance procedures.

Installation Process

Proper installation of the Studded Flange Cap Screw involves several steps to ensure optimal performance. Begin by cleaning the mating surfaces to remove any debris or contaminants. Next, align the screw with the designated hole and begin threading it into place. Use a torque wrench to tighten the screw to the manufacturer’s specified torque settings, ensuring even clamping force. Avoid over-tightening, as this can lead to damage or stripping of the threads.

Troubleshooting and Maintenance

Common issues with Studded Flange Cap Screws include loosening due to vibration or corrosion. Regular inspection and maintenance can help identify and address these issues before they lead to component failure. If corrosion is detected, clean the affected areas and consider applying a corrosion-resistant coating. For screws that have loosened, re-tighten to the specified torque settings or replace if damage is present.

Common Applications

The Studded Flange Cap Screw is utilized in various applications across different truck systems. It is commonly found in engine assemblies, where it secures components such as cylinder heads and valve covers. In transmission systems, it fastens housings and covers. Additionally, it is used in chassis and suspension components, ensuring these critical parts remain securely attached.

Safety Considerations

When working with Studded Flange Cap Screws, it is important to follow safety protocols to prevent injury and ensure proper handling. Always wear appropriate personal protective equipment, such as gloves and safety glasses. Store screws in a dry, organized environment to prevent corrosion and damage. Dispose of any damaged or unusable screws according to local regulations to avoid environmental harm.

Cummins Overview

Cummins is a renowned manufacturer in the automotive industry, known for its commitment to quality and innovation. With a history of producing reliable and high-performance components, Cummins has established a reputation for excellence. Their Studded Flange Cap Screw is a testament to their dedication to providing durable and efficient solutions for the heavy-duty truck market.

Cummins Studded Flange Cap Screw 4058673 in Engine Applications

The Cummins Studded Flange Cap Screw, part number 4058673, is a critical component in the assembly and maintenance of various engine configurations. This particular screw is integral to the structural integrity and operational efficiency of the engines it is used in.

N14 CELECT PLUS and N14 MECHANICAL Engines

In the N14 CELECT PLUS and N14 MECHANICAL engines, the 4058673 Studded Flange Cap Screw plays a pivotal role in securing various flanges and components. These engines, known for their robust design and reliability, utilize this screw to ensure that critical parts remain tightly fastened under high operational stresses. The screw’s studded design provides enhanced grip and stability, which is essential for maintaining the alignment and integrity of the engine’s components.

The use of this screw in these engines highlights its importance in both the assembly process and ongoing maintenance. Its design ensures that the flanges and other components it secures do not loosen over time, which is crucial for the safe and efficient operation of the engine.

The precision and durability of the 4058673 Studded Flange Cap Screw make it a preferred choice for these high-performance engines, ensuring that they can withstand the rigors of continuous operation.

Role of Part 4058673 Studded Flange Cap Screw in Engine Systems

The Part 4058673 Studded Flange Cap Screw is an essential component in various engine systems, providing secure and reliable fastening for multiple assemblies. Its primary function is to ensure that components remain firmly in place under operational conditions, thereby contributing to the overall stability and performance of the engine.

Mounting Applications

In engine mounting applications, the Studded Flange Cap Screw plays a significant role. It is used to fasten the engine to its mounting brackets, ensuring that the engine remains securely positioned within the vehicle’s chassis. This secure attachment is vital for absorbing vibrations and minimizing movement during operation, which helps in maintaining alignment and reducing wear on both the engine and the chassis.

Oil Pan Assembly

The oil pan is another area where the Studded Flange Cap Screw is frequently employed. It is used to attach the oil pan to the engine block, creating a sealed environment that retains engine oil. The screw’s studded flange design provides additional sealing surface area, which enhances the integrity of the oil pan’s attachment. This is particularly important in high-performance engines where oil pressure and temperature can vary significantly.

Oil Pan Service Kit

When performing maintenance or repairs on the oil pan, the Studded Flange Cap Screw is often included in oil pan service kits. These kits are designed to facilitate the reassembly of the oil pan after servicing, ensuring that all components are correctly and securely reattached. The use of high-quality screws like the Part 4058673 ensures that the oil pan remains leak-free and durable, contributing to the longevity of the engine.

General Pan Applications

Beyond the oil pan, the Studded Flange Cap Screw is also used in various other pan applications within the engine system. This includes sump pans, transmission pans, and other fluid containment pans. The screw’s design allows for a tight and secure fit, which is essential for preventing leaks and maintaining the structural integrity of these pans.

Oil System Integrity

Overall, the Part 4058673 Studded Flange Cap Screw is integral to maintaining the integrity of the engine’s oil system. By securely fastening critical components such as the oil pan and other fluid containment pans, it ensures that the engine’s lubrication system operates efficiently. This, in turn, helps in reducing friction, wear, and tear on moving parts, ultimately contributing to the engine’s performance and longevity.

Conclusion

The Studded Flange Cap Screw, part number 4058673, is a critical component in the automotive industry, particularly for heavy-duty trucks. Its design and features make it suitable for various applications, ensuring secure fastening and reliable performance under demanding conditions. Proper installation, regular maintenance, and adherence to safety protocols are essential for maximizing the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.