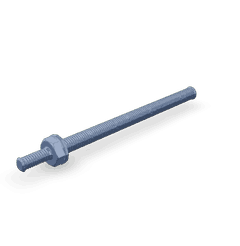

4057851

Studded Flange Cap Screw

Cummins®

IN STOCK

6 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Studded Flange Cap Screw, identified by Part #4057851, is a component manufactured by Cummins, a well-established name in the automotive and heavy-duty truck industry. This screw is integral to the mechanical systems of commercial trucks, ensuring secure fastening and reliable operation of various components.

Basic Concepts

A Studded Flange Cap Screw is a type of fastener that includes a threaded stud with a flange at one end and is designed to be used with a nut. The flange provides a larger surface area for distribution of clamping force, which enhances the screw’s ability to hold components securely in place. Within a truck’s mechanical system, it plays a role in fastening critical components, ensuring they remain securely attached under various operational conditions 1.

Purpose and Role

The Studded Flange Cap Screw serves a pivotal role in the operation of a truck by securing components that are subject to significant stress and vibration. Its applications span across various truck systems, including engine mounts, exhaust systems, and chassis components. The screw’s design allows it to withstand high loads and vibrations, contributing to the overall reliability and safety of the vehicle 2.

Key Features

The Studded Flange Cap Screw is characterized by several key features that enhance its performance. It is typically made from high-strength materials, such as alloy steel, to ensure durability under demanding conditions. The flange design distributes clamping force more effectively, reducing the risk of component failure. Additionally, the screw’s threaded stud allows for easy installation and removal, facilitating maintenance procedures 3.

Benefits

Utilizing a Studded Flange Cap Screw in truck maintenance and operation offers several advantages. Its robust construction and design contribute to increased durability, ensuring long-term reliability. The efficient distribution of clamping force enhances the screw’s ability to hold components securely, even under dynamic loads. Furthermore, the ease of installation and removal supports efficient maintenance practices, reducing downtime and operational costs.

Installation Process

Proper installation of the Studded Flange Cap Screw involves several steps to ensure secure fastening and optimal performance. Begin by cleaning the mating surfaces to remove any debris or contaminants. Apply a suitable thread lubricant to the screw’s threads to facilitate installation and prevent galling. Insert the screw through the designated hole and secure it with a nut, ensuring the flange is flush against the component. Tighten the nut to the manufacturer’s specified torque setting to achieve the correct clamping force without over-tightening, which could damage the screw or the component.

Troubleshooting and Maintenance

Common issues with Studded Flange Cap Screws include loosening due to vibration or corrosion, and damage from over-tightening. Regular inspection for signs of wear, corrosion, or loosening is recommended. If corrosion is detected, cleaning the affected area and applying a corrosion-resistant coating can help prevent further degradation. In cases of loosening, re-tightening to the specified torque setting is necessary. For damaged screws, replacement is advised to maintain system integrity.

Common Applications

The Studded Flange Cap Screw is commonly applied in various systems within commercial trucks. It is frequently used in engine mounts to secure the engine to the chassis, in exhaust systems to hold components in place, and in chassis applications to fasten structural elements. Its versatility and reliability make it a preferred choice for applications where secure fastening is critical.

Safety Considerations

When working with the Studded Flange Cap Screw, it is important to observe several safety guidelines. Ensure the truck is securely supported on jack stands before beginning any work to prevent accidental movement. Use the correct tools for installation and removal to avoid damage to the screw or surrounding components. Follow the manufacturer’s torque specifications to prevent over-tightening, which could lead to component failure. Additionally, wear appropriate personal protective equipment, such as gloves and safety glasses, to protect against injury from sharp edges or flying debris.

Cummins Overview

Cummins is a renowned manufacturer in the automotive and heavy-duty truck industry, with a history of innovation and commitment to quality. Established in 1919, Cummins has built a reputation for producing reliable and high-performance components. Their dedication to research and development ensures that their products, including the Studded Flange Cap Screw, meet the demanding requirements of commercial truck applications.

Studded Flange Cap Screw (Part 4057851) in Cummins Engines

The Studded Flange Cap Screw, identified as part number 4057851, is a critical component in various Cummins engines. This part is designed to secure flanges and other components in the engine assembly, ensuring a tight and reliable connection.

Application in Cummins Engines

-

QSK19 CM2350 K105, QSK19 CM2350 K114, and QSK19 CM2350 K144G

These engines utilize the Studded Flange Cap Screw in several key areas. The screw is often used in the exhaust system, where it helps to maintain the integrity of flange connections. This is crucial for preventing leaks and ensuring the engine operates efficiently. Additionally, it is employed in securing various engine covers and housings, contributing to the overall structural integrity of the engine.

-

QSK19 CM850 MCRS

In the QSK19 CM850 MCRS engine, the Studded Flange Cap Screw is integral to the engine’s cooling system. It is used to fasten components that are exposed to high temperatures and pressures, ensuring that these parts remain securely in place under demanding conditions. The screw’s design allows for easy installation and removal, which is essential during maintenance and repair operations.

The use of this part across these engines highlights its versatility and importance in maintaining the functionality and reliability of Cummins engines.

Role of Part 4057851 Studded Flange Cap Screw in Engine Systems

The 4057851 studded flange cap screw is integral to the secure assembly and operation of various engine components. Its primary function is to provide a robust fastening solution that ensures components remain firmly in place under the dynamic and high-stress conditions of engine operation.

Crankcase Breather Arrangement

In the crankcase breather arrangement, the 4057851 screw is used to secure the breather housing to the crankcase. This ensures that the breather system effectively vents pressure and contaminants from the crankcase, maintaining optimal engine performance and longevity.

Turbocharger Mounting

When it comes to turbochargers, the 4057851 screw plays a significant role in mounting the turbocharger to the engine. This secure attachment is vital for the turbocharger to operate efficiently, enhancing engine performance by providing forced induction.

Engine Oil Cooler

In the engine oil cooler system, the 4057851 screw is employed to fasten the cooler to its designated mounting points. This ensures that the oil cooler remains stable and effectively dissipates heat from the engine oil, contributing to consistent engine temperature and performance.

Manifold and Air Intake

For the manifold and air intake systems, the 4057851 screw is utilized to secure these components to the engine block. This ensures a sealed and stable connection, which is essential for efficient air flow into the engine, directly impacting combustion efficiency and overall engine performance.

Alternator Attachment

The 4057851 screw is also crucial in attaching the alternator to the engine. This secure mounting is necessary for the alternator to function correctly, providing the electrical power needed for the engine’s operation and the vehicle’s electrical systems.

Overall, the 4057851 studded flange cap screw is a versatile and essential component in various engine systems, ensuring that critical parts are securely fastened, thereby contributing to the engine’s reliability and performance.

Conclusion

The Studded Flange Cap Screw (Part 4057851) is a vital component in the automotive and heavy-duty truck industry, particularly for Cummins engines. Its robust design, ease of installation, and critical role in securing various engine components make it indispensable for maintaining engine reliability and performance. Proper installation, regular maintenance, and adherence to safety guidelines are essential for maximizing the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.