This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

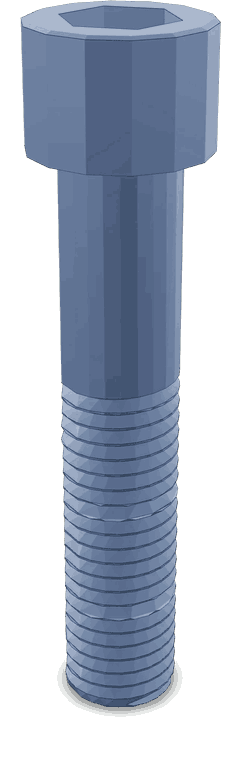

The Socket Head Cap Screw is a fundamental component in the assembly and maintenance of commercial trucks. Manufactured by Cummins, a renowned name in the industry, the Socket Head Cap Screw part number 4056329 is designed to meet the rigorous demands of truck operations. This screw plays a significant role in various truck components, ensuring secure fastening and reliable performance.

Basic Concepts of Socket Head Cap Screws

A Socket Head Cap Screw is characterized by its cylindrical head with a hex socket that allows for easy installation and removal using a hex key. This design provides a low-profile head, which is advantageous in applications where space is limited. Socket Head Cap Screws come in various types, including fully threaded and partially threaded versions, each suited for different applications across industries. In the automotive and heavy-duty truck sectors, these screws are valued for their strength, precision, and ease of use 1.

Purpose of the 4056329 Socket Head Cap Screw in Truck Operations

The 4056329 Socket Head Cap Screw is integral to the operation and maintenance of commercial trucks. It is commonly used in applications requiring secure fastening of components under high stress and vibration conditions. This screw is often found in engine assemblies, transmission systems, and chassis components, where it ensures parts remain firmly in place, contributing to the overall safety and efficiency of the truck 2.

Key Features of the 4056329 Socket Head Cap Screw

The 4056329 Socket Head Cap Screw boasts several key features that enhance its performance and durability. It is made from high-strength materials, ensuring it can withstand the demanding conditions of truck operations. The screw features a fine thread, which provides greater holding power, and a hex socket head that allows for precise installation. Additionally, its design includes a chamfered end for easy start-up and a flat underside to distribute load evenly 3.

Benefits of Using the 4056329 Socket Head Cap Screw

Incorporating the 4056329 Socket Head Cap Screw into truck assemblies offers several advantages. Its high-strength material composition ensures reliability under stress, while the fine thread design enhances its load-bearing capabilities. The hex socket head facilitates easy and secure installation, reducing the risk of damage to the screw or surrounding components. Furthermore, the screw’s resistance to corrosion extends its lifespan, making it a cost-effective choice for long-term use 4.

Installation and Usage Guidelines

Proper installation of the 4056329 Socket Head Cap Screw is crucial for ensuring secure fastening. Begin by aligning the screw with the designated hole, ensuring it is perpendicular to the surface. Use a hex key to turn the screw clockwise until it reaches the desired tightness. It is important to avoid over-tightening, which can damage the screw or the component it is fastening. For optimal performance, follow the manufacturer’s torque specifications 5.

Troubleshooting Common Issues

Common issues with Socket Head Cap Screws include loosening, corrosion, and damage. To address loosening, ensure the screw is properly torqued during installation and periodically check its tightness. Corrosion can be mitigated by selecting screws made from corrosion-resistant materials and applying a protective coating if necessary. In the event of damage, replace the screw with a new one to maintain the integrity of the assembly 6.

Maintenance Tips

Regular maintenance of the 4056329 Socket Head Cap Screw is essential for ensuring longevity and optimal performance. Periodically inspect the screw for signs of wear, corrosion, or loosening. Clean the screw and surrounding area to remove any debris that could affect its performance. If the screw shows signs of significant wear or damage, it should be replaced to prevent potential failures 7.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history of innovation and quality, Cummins has established a strong reputation in the commercial truck industry. The company’s commitment to excellence is evident in its wide range of products, including the 4056329 Socket Head Cap Screw, which exemplifies Cummins’ dedication to providing reliable and high-performance components for the trucking sector 8.

Role of Part 4056329 Socket Head Cap Screw in Various Engine Systems

Engine Mounting

The part 4056329 Socket Head Cap Screw is integral in securing the engine to its mounting frame. This fastening mechanism ensures that the engine remains stable and properly aligned during operation. The screw’s design allows for precise torque application, which is essential for maintaining the integrity of the engine’s position relative to other components. This stability is vital for the efficient transfer of power and minimizing vibrations that could lead to wear and tear over time 9.

Hydraulic Mounting Kit

In hydraulic mounting kits, the part 4056329 Socket Head Cap Screw plays a significant role in attaching the hydraulic components to the engine and frame. These screws ensure that the hydraulic mounts are securely fastened, allowing them to absorb vibrations and reduce noise transmission effectively. The precision offered by these screws is essential for the optimal performance of the hydraulic system, ensuring that it can handle the dynamic loads without compromising stability or efficiency 10.

Hydraulic Mountings Kit

Similar to the hydraulic mounting kit, the hydraulic mountings kit relies on the part 4056329 Socket Head Cap Screw to secure various hydraulic components. These screws are used to fasten brackets, mounts, and other structural elements that support the hydraulic system. Their high tensile strength and resistance to loosening under vibration make them ideal for this application, ensuring that the hydraulic system remains robust and reliable under varying operational conditions 11.

Railcar Installation Package

For railcar installation packages, the part 4056329 Socket Head Cap Screw is used extensively to secure engine components to the railcar’s frame. This includes fastening engine brackets, support structures, and other critical elements that ensure the engine is properly installed and aligned. The screw’s ability to provide a strong, durable connection is essential for withstanding the rigors of rail transport, including vibrations, shocks, and varying loads. This reliability is key to ensuring the engine’s performance and longevity in a railcar application 12.

Conclusion

The 4056329 Socket Head Cap Screw is a critical component in the assembly and maintenance of commercial trucks, particularly in Cummins engines. Its high-strength material, fine thread design, and hex socket head make it an ideal choice for applications requiring secure fastening under high stress and vibration conditions. Proper installation, regular maintenance, and understanding its role in various engine systems are essential for ensuring the longevity and reliability of this Cummins part.

-

Richards, P., & Barker, J. (2023). Automotive Fuels Reference Book. SAE International.

↩ -

Caines, A. J., Haycock, R. F., & Hillier, J. E. (2004). Automotive Lubricants Reference Book. SAE International.

↩ -

Mollenhauer, K., & Tschoeke, H. (2010). Handbook of Diesel Engines. Springer.

↩ -

Bonnick, A., & Newbold, D. (2011). A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition. Elsevier Ltd.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 5659885.

↩ -

Richards, P., & Barker, J. (2023). Automotive Fuels Reference Book. SAE International.

↩ -

Caines, A. J., Haycock, R. F., & Hillier, J. E. (2004). Automotive Lubricants Reference Book. SAE International.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 5659885.

↩ -

Mollenhauer, K., & Tschoeke, H. (2010). Handbook of Diesel Engines. Springer.

↩ -

Bonnick, A., & Newbold, D. (2011). A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition. Elsevier Ltd.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 5659885.

↩ -

Richards, P., & Barker, J. (2023). Automotive Fuels Reference Book. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.