This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Socket Head Cap Screw Part #4025375 by Cummins is a specialized fastener designed for use in commercial truck operations. This screw plays a significant role in ensuring the secure assembly of various truck components, contributing to the overall reliability and performance of commercial vehicles. Its design and material composition are tailored to withstand the demanding conditions encountered in heavy-duty truck applications 1.

Basic Concepts of Socket Head Cap Screws

Socket Head Cap Screws are a type of fastener characterized by a hexagonal socket in the head, allowing for efficient and secure tightening using a hex key. In the automotive industry, these screws are widely used due to their ability to provide strong, permanent fastening solutions. Mechanically, they function by converting torque applied through the socket into clamping force, which holds components together securely 2.

Purpose of the 4025375 Socket Head Cap Screw in Truck Operations

This Cummins part is integral to the operation and maintenance of commercial trucks. It is utilized in various applications across truck components, including engine assemblies, transmission systems, and chassis structures. This screw ensures that critical parts remain securely fastened, which is vital for the safe and efficient operation of the vehicle 3.

Key Features of the 4025375 Socket Head Cap Screw

The 4025375 is distinguished by several key features. It is composed of high-strength materials, ensuring durability under heavy loads and harsh conditions. The screw’s design specifications include a precise hexagonal socket for easy installation and removal, as well as a cap head that provides additional strength and resistance to loosening. These attributes enhance its performance and longevity in commercial truck applications.

Benefits of Using the 4025375 Socket Head Cap Screw

Utilizing this part in commercial truck applications offers several advantages. Its robust construction and precise design contribute to improved reliability, reducing the likelihood of fastener failure. The ease of installation with a hex key minimizes downtime during maintenance procedures. Additionally, the screw’s durability leads to long-term cost savings by reducing the need for frequent replacements.

Installation and Usage Guidelines

Proper installation of the 4025375 is crucial for optimal performance. It should be installed using the recommended torque settings to ensure the correct clamping force is achieved without over-tightening, which could damage the screw or the components being fastened. Best practices include using a calibrated torque wrench and following manufacturer guidelines for installation procedures.

Troubleshooting Common Issues

Common issues with the 4025375 may include loosening, corrosion, or damage. To address these problems, regular inspections should be conducted to identify any signs of wear or corrosion. If loosening is detected, re-tightening to the specified torque settings may resolve the issue. In cases of corrosion, cleaning the screw and applying a suitable corrosion-resistant coating can help prevent further degradation.

Maintenance Tips

To prolong the lifespan of the 4025375, regular maintenance is recommended. This includes periodic inspections for signs of wear, corrosion, or damage. Cleaning the screw and its surrounding area can prevent the buildup of contaminants that may lead to corrosion. When significant wear or damage is observed, considering replacement with a new screw is advisable to maintain the integrity of the fastened components.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company’s commitment to excellence is evident in its wide range of products, including the 4025375, which exemplifies Cummins’ dedication to providing reliable and high-performance components for commercial vehicles.

Socket Head Cap Screw 4025375 in Cummins Engines

The Socket Head Cap Screw 4025375, manufactured by Cummins, is a critical component in various Cummins engine models. This part is integral to the assembly and maintenance of the engines, ensuring secure fastening and structural integrity.

QST30 CM2350 T101

In the QST30 CM2350 T101 engine, the Socket Head Cap Screw 4025375 is used in several key areas. It plays a vital role in securing various engine components, ensuring that parts remain tightly fastened under operational stresses. This screw is particularly important in maintaining the alignment and stability of the engine’s internal and external structures.

QST30 CM552

Similarly, in the QST30 CM552 engine, the Socket Head Cap Screw 4025375 is utilized to fasten components that are critical to the engine’s performance and durability. Its design allows for easy installation and removal, which is essential during routine maintenance and repairs. This screw helps in maintaining the precise alignment of engine parts, contributing to the overall efficiency and longevity of the engine.

Grouping of Engines

Both the QST30 CM2350 T101 and QST30 CM552 engines share a common requirement for the Socket Head Cap Screw 4025375. This commonality underscores the importance of this part in Cummins engine designs, where it is used to ensure that various components are securely fastened. The use of this screw in both engines highlights its versatility and critical role in maintaining engine integrity.

Role of Part 4025375 Socket Head Cap Screw in Engine Systems

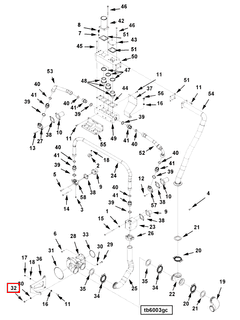

The 4025375 Socket Head Cap Screw is integral to the assembly and functionality of various engine systems. In the system component, this screw is often used to secure critical components, ensuring that parts remain firmly in place under the high stresses and vibrations typical in engine operation. Its design allows for a high torque application, which is essential for maintaining the integrity of the system’s structure.

In the auxiliary cooling system, the 4025375 Socket Head Cap Screw plays a significant role in attaching cooling fins, brackets, and other components that facilitate heat dissipation. The screw’s robust construction ensures that these components remain securely fastened, even under the thermal expansion and contraction cycles that occur during engine operation.

For the water pump component, the 4025375 Socket Head Cap Screw is utilized to fasten the pump housing, impeller, and other critical parts. This ensures that the water pump operates efficiently by maintaining the alignment and integrity of its components. The screw’s ability to withstand high torque and corrosion makes it ideal for this application, contributing to the reliable performance of the cooling system.

Conclusion

The 4025375 Socket Head Cap Screw by Cummins is a vital component in the maintenance and operation of commercial trucks and Cummins engines. Its robust design, ease of installation, and durability make it an essential fastener for ensuring the secure assembly of critical components. Regular maintenance and proper installation practices are key to maximizing the lifespan and performance of this part, contributing to the overall reliability and efficiency of commercial vehicles.

-

Bennett, S. (2012). Modern Diesel Technology: Light Duty Diesels. Cengage Learning.

↩ -

Van Gelder, K. T. (2018). Fundamentals of Automotive Technology Principles and Practice. Jones Bartlett Learning.

↩ -

Taghavifar, H., & Mardani, A. (2017). Offroad Vehicle Dynamics Analysis Modelling and Optimization. Springer.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.