This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

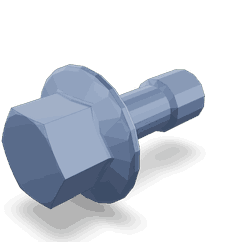

The 4012906 Hexagon Flange Head Cap Screw, manufactured by Cummins, is a vital component in the commercial truck industry. Cummins, renowned for its quality and innovation, produces this screw to meet the rigorous demands of heavy-duty applications 1.

Basic Concepts

A Hexagon Flange Head Cap Screw is characterized by its hexagonal head and flanged base. The hexagonal head facilitates efficient torque application using standard tools, while the flange provides a larger bearing surface that helps distribute load and resist loosening 2. These screws are used to secure components in mechanical systems, ensuring stability and integrity under various operational conditions.

Purpose and Role in Truck Operation

This Cummins part is essential in the operation and maintenance of commercial trucks. It is commonly used in areas requiring secure fastening, such as engine components, chassis parts, and other critical assemblies. Its design ensures that components remain firmly attached, even under significant stress and vibration 3.

Key Features

The 4012906 Hexagon Flange Head Cap Screw features a hexagonal head for easy and precise tightening, a flange for increased contact area to enhance resistance to loosening, and is made from high-quality materials offering excellent strength and corrosion resistance 4.

Benefits

Using this screw in truck maintenance and repair offers several advantages. Its design enhances stability by providing a secure fastening solution that resists loosening over time, which is particularly beneficial in applications where vibrations are common. Additionally, the ease of installation using standard tools reduces maintenance time and labor costs.

Installation and Usage

Proper installation of the 4012906 Hexagon Flange Head Cap Screw is crucial for ensuring secure fastening. It is recommended to use a torque wrench to apply the correct amount of force, preventing over-tightening or under-tightening. The screw should be installed in a clean, undamaged thread to ensure a proper fit and maximum holding power. Following manufacturer guidelines for torque specifications is essential to achieve optimal performance 5.

Troubleshooting and Maintenance

Common issues with Hexagon Flange Head Cap Screws include loosening due to vibration and corrosion in harsh environments. Regular inspections should be conducted to ensure screws remain tight and free from corrosion. If loosening is detected, re-tightening with the appropriate torque is necessary. In cases of corrosion, screws may need to be replaced to maintain structural integrity 6.

Safety Considerations

When working with Hexagon Flange Head Cap Screws, it is important to observe several safety practices. Always use the correct tools to avoid damage to the screw or surrounding components. Ensure that all safety protocols are followed when performing maintenance tasks, especially when working on live machinery. Additionally, wearing appropriate personal protective equipment (PPE) can help mitigate potential hazards 7.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a trusted name in the commercial truck industry. The company is committed to innovation and quality, ensuring that its products, including the 4012906 Hexagon Flange Head Cap Screw, meet the highest standards of performance and reliability 8.

Role of Part 4012906 Hexagon Flange Head Cap Screw in Engine Systems

The 4012906 Hexagon Flange Head Cap Screw is instrumental in securing various components within engine systems, ensuring stability and reliable operation.

Governor Systems

In governor systems, the 4012906 screw is often used to fasten the governor housing to the engine block. This secure attachment is essential for maintaining the alignment and integrity of the governor mechanism, which regulates engine speed by controlling fuel delivery.

Electronic Systems

Within electronic engine control systems, the 4012906 screw plays a role in mounting sensors and actuators. These components require precise positioning to ensure accurate data collection and responsive control actions. The screw’s flange head provides additional surface area for a firm grip, reducing the risk of sensor or actuator movement during operation.

Valve Mechanisms

For valve mechanisms, the 4012906 screw is commonly employed to attach valve covers and other housing components. This ensures that the valve train remains enclosed and protected from contaminants, while also maintaining the necessary pressure within the valve system. The robust design of the screw helps withstand the dynamic forces exerted during engine operation.

Throttle Systems

In throttle systems, the 4012906 screw is used to secure the throttle body to the intake manifold. This connection is vital for maintaining the airtight seal required for efficient air intake, directly influencing engine performance and fuel efficiency. The screw’s design allows for easy adjustment and re-tightening, accommodating the natural wear and thermal expansion that occur during engine use.

Conclusion

The 4012906 Hexagon Flange Head Cap Screw is a critical component in the assembly and maintenance of engine systems. Its robust design, ease of installation, and resistance to loosening make it an essential part for ensuring the reliability and longevity of engine components. Proper installation, regular maintenance, and adherence to safety protocols are vital for maximizing the performance and lifespan of this screw in heavy-duty applications.

-

Huzij, R., Spano, A., & Bennett, S. (2019). Modern Diesel Technology: Heavy Equipment Systems. Cengage Learning.

↩ -

Limpert, R. (2011). Brake Design and Safety, Third Edition. SAE International.

↩ -

Reif, K. (Ed.). (2014). Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg.

↩ -

Cummins Inc. (n.d.). Owners Manual for QSL9 G CM558/CM2358. Bulletin Number 2883373.

↩ -

Huzij, R., Spano, A., & Bennett, S. (2019). Modern Diesel Technology: Heavy Equipment Systems. Cengage Learning.

↩ -

Limpert, R. (2011). Brake Design and Safety, Third Edition. SAE International.

↩ -

Reif, K. (Ed.). (2014). Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg.

↩ -

Cummins Inc. (n.d.). Owners Manual for QSL9 G CM558/CM2358. Bulletin Number 2883373.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.