4006201

Twelve Point Cap Screw

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins Twelve-Point Cap Screw (Part #4006201) is a specialized fastener designed for commercial truck maintenance and operation. This component ensures the secure assembly of various truck components, contributing to the overall reliability and performance of commercial vehicles. Its design and material composition are tailored to withstand the demanding conditions encountered in heavy-duty truck applications 1.

Basic Concepts of Twelve-Point Cap Screws

A twelve-point cap screw is a fastener characterized by its hexagonal-shaped head with twelve points, as opposed to the six points found on traditional hex cap screws. This design offers several advantages, including improved torque application and reduced likelihood of cam-out during tightening. In the automotive industry, twelve-point cap screws are commonly used in applications where high strength and resistance to loosening are required 2.

Purpose and Role in Truck Operation

This Cummins part plays a significant role in the operation and maintenance of commercial trucks. It is utilized in various truck components, such as engine assemblies, transmission systems, and chassis structures. By providing a secure and durable fastening solution, this cap screw helps maintain the integrity of critical truck systems, ensuring safe and efficient operation 3.

Key Features

The 4006201 features a robust design that includes a twelve-point head for enhanced torque application and resistance to cam-out. It is manufactured from high-strength materials, ensuring durability and reliability in demanding environments. Additionally, the screw’s design incorporates features that enhance its performance, such as a precise thread profile for optimal engagement and a corrosion-resistant coating to protect against environmental factors 4.

Benefits

This part offers several benefits, including improved fastening security due to its twelve-point design, which allows for better torque application and reduced risk of loosening. Its high-strength material composition ensures longevity and reliability in demanding truck applications. The corrosion-resistant coating further enhances its durability, making it suitable for use in various environmental conditions 5.

Installation Guidelines

Proper installation of the 4006201 is crucial for ensuring optimal performance. It is recommended to use a torque wrench to apply the specified torque during installation, as outlined in the manufacturer’s guidelines. Additionally, it is important to ensure that the mating surfaces are clean and free of debris to promote proper engagement and prevent damage to the fastener or the component being secured 6.

Troubleshooting and Maintenance

Common issues associated with twelve-point cap screws include loosening due to vibration or inadequate torque application. To address these issues, it is important to regularly inspect fasteners for signs of loosening and re-torque as necessary. Additionally, maintaining clean and debris-free mating surfaces can help prevent damage to the fastener and ensure continued reliable performance 7.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is committed to providing innovative and reliable solutions for the automotive industry. The company’s product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of commercial truck applications. Cummins’ commitment to quality and innovation ensures that its products, including the 4006201, deliver exceptional performance and durability 8.

Role of Part 4006201 Twelve-Point Cap Screw in Engine Systems

This part is an essential component in securing and maintaining the integrity of various engine systems. Its primary function is to provide a robust and reliable fastening solution that ensures components remain securely in place under high stress and dynamic conditions.

Camshaft Assembly

In the camshaft assembly, the Twelve-Point Cap Screw is used to secure the camshaft to the cylinder head. This ensures that the camshaft remains aligned and operates smoothly, which is vital for the precise timing of valve operations. The screw’s design allows for easy installation and removal, facilitating maintenance and adjustments 9.

Connecting Rod and Piston

Within the connecting rod and piston assembly, this part plays a role in securing the connecting rod to the crankshaft. This connection is subjected to significant forces during engine operation, and the screw’s strength and design help maintain the structural integrity of the assembly, ensuring smooth and efficient power transmission from the piston to the crankshaft 10.

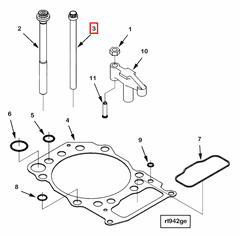

Cylinder Head

The cylinder head is another area where the Twelve-Point Cap Screw is extensively used. It secures various components such as the head bolts, ensuring a tight seal between the cylinder head and the engine block. This seal is essential for maintaining compression and preventing leaks, which are vital for engine performance and efficiency 11.

Fuel Manifold

In the fuel manifold system, the Twelve-Point Cap Screw is employed to secure the manifold to the engine. This ensures that the fuel delivery system remains intact, providing consistent fuel distribution to the cylinders. The screw’s reliability under pressure helps maintain the manifold’s structural integrity, contributing to overall engine performance 12.

Injector and Injector Plumbing

For the injector and injector plumbing, the Twelve-Point Cap Screw is used to secure injectors in place and to fasten plumbing components. This ensures that fuel injectors operate within specified parameters, delivering the correct amount of fuel at the right time. The screw’s design also aids in the secure attachment of plumbing components, preventing leaks and ensuring efficient fuel delivery 13.

Lever and Rocker Arm Assembly

In the lever and rocker arm assembly, the Twelve-Point Cap Screw is critical for securing the rocker arms to the camshaft and the engine block. This connection ensures that the rocker arms operate smoothly, translating the camshaft’s motion into valve actuation. The screw’s strength and precision fitting are essential for maintaining the accuracy and reliability of valve timing 14.

General Performance and Maintenance

Across all these applications, the Twelve-Point Cap Screw contributes to the overall performance and reliability of the engine. Its design allows for easy torque application, reducing the risk of over-tightening or stripping, which can lead to component failure. Additionally, the screw’s corrosion resistance ensures longevity, even in harsh operating environments 15.

Conclusion

In summary, the 4006201 is a versatile and reliable fastening solution that plays a significant role in maintaining the structural integrity and performance of various engine components. Its design and material composition are tailored to withstand the demanding conditions encountered in heavy-duty truck applications, ensuring secure and durable fastening solutions across multiple engine systems.

-

Ferrari, A., & Pizzo, P. (2022). Injection Technologies: Mixture Formation Strategies. SAE International.

↩ -

Singh, D. K. (2024). Dictionary of Mechanical Engineering. Springer Nature.

↩ -

Xin, Q. (2011). Diesel Engine System Design. Woodhead Publishing Limited.

↩ -

Cummins Inc. (n.d.). Service Manual (5504515). Cummins Inc.

↩ -

Cummins Inc. (n.d.). Service Manual (5504515). Cummins Inc.

↩ -

Cummins Inc. (n.d.). Service Manual (5504515). Cummins Inc.

↩ -

Cummins Inc. (n.d.). Service Manual (5504515). Cummins Inc.

↩ -

Cummins Inc. (n.d.). Service Manual (5504515). Cummins Inc.

↩ -

Cummins Inc. (n.d.). Service Manual (5504515). Cummins Inc.

↩ -

Cummins Inc. (n.d.). Service Manual (5504515). Cummins Inc.

↩ -

Cummins Inc. (n.d.). Service Manual (5504515). Cummins Inc.

↩ -

Cummins Inc. (n.d.). Service Manual (5504515). Cummins Inc.

↩ -

Cummins Inc. (n.d.). Service Manual (5504515). Cummins Inc.

↩ -

Cummins Inc. (n.d.). Service Manual (5504515). Cummins Inc.

↩ -

Cummins Inc. (n.d.). Service Manual (5504515). Cummins Inc.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.