This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

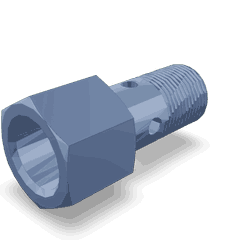

The 4002006 Banjo Connector Screw, manufactured by Cummins, is a component designed for use in commercial truck operations. Cummins, a well-established name in the industry, produces a range of parts that contribute to the efficiency and reliability of heavy-duty vehicles. This part plays a role in the fluid systems of trucks, ensuring secure and leak-proof connections 1.

Basic Concepts of Banjo Connector Screws

A Banjo Connector Screw is a type of fitting used in fluid systems to connect hoses or pipes to various components. It typically consists of a bolt with a flat, circular flange that has a hole drilled through it. This design allows for the secure attachment of hoses or pipes, ensuring a tight seal that prevents fluid leaks. In a truck’s hydraulic or fuel system, these connectors are vital for maintaining the integrity of the fluid pathways, ensuring that systems operate efficiently and safely 2.

Purpose of the 4002006 Banjo Connector Screw

This Cummins part serves a specific function within a truck’s system by connecting hoses or pipes to fittings. It ensures a secure seal, which is important for the proper operation of hydraulic or fuel systems. This part is designed to withstand the pressures and conditions typical in commercial truck applications, providing a reliable connection point for fluid lines 3.

Key Features

The 4002006 is characterized by several key features that enhance its performance and durability. These include its material composition, which is typically made from high-strength steel to resist wear and corrosion. The thread type is designed for a secure fit, and the overall design incorporates elements that facilitate easy installation while maintaining a robust seal.

Benefits

Using the 4002006 offers several benefits. Its design contributes to improved sealing capabilities, reducing the risk of leaks in fluid systems. The material used in its construction provides resistance to corrosion, extending its service life. Additionally, the screw is designed for ease of installation, allowing for quick and efficient connections in maintenance or repair scenarios.

Installation Process

Installing the 4002006 requires following a specific process to ensure a secure and leak-free connection. The steps include preparing the fitting and hose or pipe, applying the appropriate sealant if necessary, threading the screw into the fitting, and tightening it to the manufacturer’s specified torque. Using the correct tools and taking precautions such as avoiding over-tightening are important to ensure the connection’s integrity.

Common Applications

This part finds common applications within commercial trucks, particularly in systems where secure fluid connections are critical. These include brake systems, where it ensures the hydraulic lines are securely connected, fuel lines, where it maintains the integrity of the fuel delivery system, and hydraulic circuits, which rely on secure connections for efficient operation.

Troubleshooting and Maintenance

When dealing with the 4002006, common issues such as leaks or loose connections can arise. Troubleshooting these problems involves checking for proper installation, ensuring the correct torque has been applied, and inspecting for signs of wear or damage. Regular maintenance, including periodic inspections and tightening as necessary, can help prolong the service life of the connector screw.

Safety Considerations

Working with the 4002006 requires adherence to safety considerations to ensure both personal safety and the reliable operation of the vehicle. This includes proper handling of the part to avoid damage, using the correct torque specifications during installation to prevent over-tightening or under-tightening, and conducting regular inspections to identify any signs of wear or potential failure.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and reliability in the commercial truck industry. Its product range includes a variety of components and systems designed to enhance the performance and efficiency of heavy-duty vehicles.

Cummins Engine Compatibility with Part 4002006

The Banjo Connector Screw, part number 4002006, manufactured by Cummins, is a component in the fuel and fluid systems of various Cummins engines. This part is designed to ensure a secure and leak-proof connection between the banjo fitting and the fuel line or hose.

ISC CM554 and ISL CM554

The ISC CM554 and ISL CM554 engines are part of Cummins’ range of medium-duty diesel engines. These engines are known for their robust performance and reliability in various applications, including heavy-duty trucks and industrial machinery. The 4002006 is used in these engines to secure the fuel lines to the fuel system components. This ensures that the fuel delivery system maintains integrity and prevents leaks, which is crucial for the engine’s optimal performance and longevity.

QSC8.3 CM554 and QSL9 CM554

The QSC8.3 CM554 and QSL9 CM554 engines are part of Cummins’ line of high-performance, heavy-duty diesel engines. These engines are typically used in applications requiring substantial power and durability, such as construction equipment and large trucks. The 4002006 is integral to these engines’ fuel systems. It provides a reliable connection for the fuel lines, ensuring that the fuel delivery system operates efficiently and safely under demanding conditions.

Application Across Engine Families

The 4002006 is designed to be compatible with the aforementioned engines, which belong to different families within the Cummins engine portfolio. Despite the differences in engine sizes and applications, this part’s design ensures it fits seamlessly into the fuel systems of the ISC CM554, ISL CM554, QSC8.3 CM554, and QSL9 CM554 engines. This compatibility highlights Cummins’ commitment to providing standardized components that can be used across various engine models, simplifying maintenance and repair processes.

Role of Part 4002006 Banjo Connector Screw in Engine Systems

The 4002006 is an integral component in the assembly and operation of various engine systems, particularly those involving fluid transfer and high-pressure applications. This screw plays a role in ensuring the secure and leak-proof connection of hydraulic lines within the engine.

In the Fuel Injection Pump system, the 4002006 is utilized to connect the high-pressure fuel lines to the pump. This connection is important for maintaining the integrity of the fuel delivery system, ensuring that fuel is delivered at the precise pressure required for efficient combustion. The secure fitting provided by the banjo connector screw prevents fuel leaks, which could otherwise lead to performance issues or safety hazards.

Within the Fuel Pump system, this component is similarly important. It ensures that the fuel lines are tightly sealed, allowing for consistent fuel flow from the pump to the engine. This is particularly important in systems where the fuel pump operates at high pressures, as any leakage could result in a drop in fuel pressure, affecting engine performance.

In broader Pump applications, the 4002006 is used to connect various hydraulic lines. Its design allows for easy installation and removal while providing a robust seal against fluid leakage. This is vital in maintaining the efficiency and reliability of the pump system, whether it is used for fuel, lubrication, or other hydraulic functions.

For the Fuel Injection system, the banjo connector screw ensures that the fuel injectors receive a consistent supply of fuel at the correct pressure. This is essential for the precise delivery of fuel into the combustion chamber, directly impacting the engine’s efficiency, power output, and emissions.

Overall, the 4002006 is a key component in ensuring the secure and efficient operation of engine systems involving fluid transfer. Its role in preventing leaks and maintaining pressure integrity is fundamental to the performance and reliability of these systems.

Conclusion

The 4002006 Banjo Connector Screw is a critical component in the maintenance and operation of commercial truck fluid systems. Its design, compatibility with various Cummins engines, and role in ensuring secure and leak-proof connections make it an essential part for the efficiency and reliability of heavy-duty vehicles. Proper installation, maintenance, and adherence to safety considerations are vital to maximizing the benefits of this Cummins part.

-

Advanced Automotive Electricity and Electronics, Michael Klyde and Kirk VanGelder, Jones Bartlett Learning, 2010.

↩ -

Advances in Engine and Powertrain Research and Technology, Tigran Parikyan Ed, Springer Nature, 2022.

↩ -

Automotive Transmissions Fundamentals Selection Design and Application, Harald Naunheimer, Bernd Bertsche, Joachim Ryborz, Wolfgang Novak, Springer Vieweg, 2011.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.