This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Shoulder Isolator Cap Screw, identified by part number 3975949, is a component manufactured by Cummins, a renowned name in the automotive and heavy-duty truck industry. This screw plays a role in the structural and mechanical integrity of heavy-duty trucks, ensuring reliable performance under demanding conditions 1.

Basic Concepts

Shoulder Isolator Cap Screws are designed to provide a secure fastening solution in various applications. These screws feature a shoulder—a cylindrical section under the head—that isolates the screw from the surface it is fastened to. This design helps in distributing loads more evenly and reducing the transmission of vibrations. In commercial trucks, these screws are commonly used in applications where both high strength and vibration isolation are required 2.

Purpose and Role in Truck Operation

The 3975949 Shoulder Isolator Cap Screw serves a specific purpose within the operational framework of a truck. It is utilized to fasten components that require both robust attachment and isolation from vibrations. By maintaining structural integrity and facilitating mechanical functions, this screw ensures that critical components remain securely in place, even under the dynamic conditions experienced by heavy-duty trucks 3.

Key Features

The 3975949 Shoulder Isolator Cap Screw boasts several key features that contribute to its performance and durability. It is typically made from high-strength materials, ensuring it can withstand the rigors of heavy-duty applications. The screw features a specific thread type designed for optimal engagement with mating components. Additionally, its unique design elements, such as the isolating shoulder, enhance its ability to perform under various operational stresses.

Benefits

The advantages offered by the 3975949 Shoulder Isolator Cap Screw are manifold. Its design contributes to enhanced stability by securely fastening components while minimizing the impact of vibrations. This results in improved load distribution across the fastening area, which is vital for the longevity and performance of the truck. The reduction in vibration also helps in minimizing wear and tear on both the screw and the components it secures.

Installation and Usage

Proper installation of the 3975949 Shoulder Isolator Cap Screw is crucial for ensuring optimal performance and safety. The installation process should follow specific torque specifications provided by the manufacturer to achieve the correct tension without over-tightening. It is also important to ensure that the surfaces where the screw will be installed are clean and free from contaminants to prevent corrosion and ensure a secure fit.

Troubleshooting and Maintenance

Regular inspection and maintenance of the 3975949 Shoulder Isolator Cap Screw can help identify common issues such as loosening or corrosion. If loosening is detected, re-torque the screw to the manufacturer’s specifications. In cases of corrosion, cleaning the affected area and applying a suitable anti-corrosion treatment can help prolong the service life of the screw. Routine checks during maintenance intervals are recommended to ensure the screw remains in optimal condition.

Cummins Overview

Cummins is a well-established company with a rich history in the automotive industry, particularly known for its high-quality components for commercial vehicles. The company’s reputation is built on a commitment to innovation, reliability, and performance. Cummins continues to be a trusted name in the industry, providing components that meet the demanding requirements of heavy-duty applications.

Role of Part 3975949 Shoulder Isolator Cap Screw in Engine Systems

The 3975949 Shoulder Isolator Cap Screw is a component in the assembly and maintenance of various engine systems. Its primary function is to provide secure fastening while also acting as an isolator to reduce vibrations and noise transmission between components.

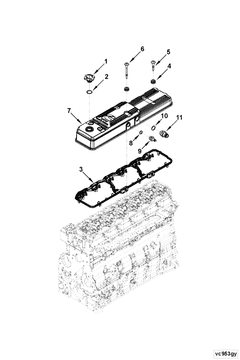

Integration with the Valve Cover

In the context of the valve cover, the 3975949 Shoulder Isolator Cap Screw plays a role in ensuring a tight and secure seal. The valve cover protects the valve train components and retains engine oil within the crankcase. The screw’s isolator feature helps in minimizing the transfer of engine vibrations to the valve cover, thereby enhancing the durability and reliability of the seal. This is particularly important in high-performance engines where vibrations can be more pronounced.

Application in the Long Block Assembly

When dealing with a long block—which includes the engine block, crankshaft, pistons, and other essential components—the 3975949 Shoulder Isolator Cap Screw is utilized in various fastening applications. It secures ancillary components such as sensors, brackets, and other attachments to the engine block. The isolation properties of the screw help in maintaining the structural integrity of the long block by reducing the impact of operational stresses and vibrations on these secondary components.

Usage in Engine Arrangements

In broader engine arrangements, the 3975949 Shoulder Isolator Cap Screw is often employed in the fastening of engine mounts, exhaust manifolds, and other peripheral components. Its ability to isolate vibrations ensures that these components remain securely fastened without undue stress, contributing to the overall stability and performance of the engine system.

Conclusion

By effectively managing vibrational forces and providing robust fastening solutions, the 3975949 Shoulder Isolator Cap Screw enhances the operational efficiency and longevity of engine components. Its role in various engine systems underscores its importance in maintaining the structural integrity and performance of heavy-duty trucks and engines.

-

Reif, Konrad. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩ -

Majewski, Addy, and Hannu Jaskelainen. Diesel Emissions and Their Control: Second Edition. SAE International, 2023.

↩ -

Viskup, Richard. Diesel and Gasoline Engines. IntechOpen, 2020.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.