This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

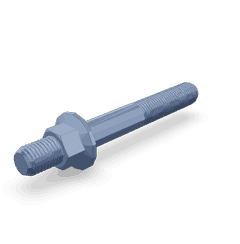

The Studded Flange Cap Screw, specifically Part #3970326 by Cummins, is a significant component in commercial truck maintenance. Cummins, a well-established manufacturer, produces this part, which is integral to the reliable operation of trucks. This screw is designed to meet the rigorous demands of heavy-duty applications, ensuring that truck systems function efficiently and effectively 1.

Basic Concepts

A Studded Flange Cap Screw is a type of fastener that features a threaded stud on one end and a flange on the other. Its general function in mechanical systems is to provide a secure connection between components, allowing for the transmission of force and the maintenance of structural integrity. In the context of a truck’s components, this screw plays a role in joining parts that require a robust and durable fastening solution 2.

Role in Truck Operation

The 3970326 Studded Flange Cap Screw is utilized in various truck systems where a strong and reliable connection is necessary. It is commonly applied in the assembly of engine components, transmission systems, and other critical areas where vibration and stress are prevalent. By providing a secure attachment point, this screw contributes to the overall stability and performance of the truck 3.

Key Features

The 3970326 Studded Flange Cap Screw is characterized by several key features that enhance its functionality. It is constructed from high-quality materials, ensuring durability and resistance to wear. The design includes a flange that distributes load more evenly across the surface, reducing the risk of damage to the connected components. Additionally, the screw’s threading is precision-engineered to provide a tight and secure fit, minimizing the potential for loosening over time 4.

Benefits

Utilizing the 3970326 Studded Flange Cap Screw offers several advantages in truck operations. Its robust construction and design contribute to improved performance by ensuring that components remain securely fastened under various operating conditions. The screw’s durability leads to enhanced reliability, reducing the frequency of maintenance interventions. Furthermore, its reliable performance supports the longevity of truck systems, contributing to overall operational efficiency 1.

Installation Process

Proper installation of the 3970326 Studded Flange Cap Screw is vital to ensure a secure fitting. The process involves selecting the appropriate tool, typically a torque wrench, to achieve the recommended tightening specification. It is important to follow the manufacturer’s guidelines for torque values to avoid over-tightening, which could damage the screw or the connected components, or under-tightening, which could lead to a loose connection. Careful attention to the installation process ensures the screw functions as intended within the truck’s system 2.

Troubleshooting and Maintenance

Common issues associated with Studded Flange Cap Screws include loosening due to vibration, corrosion, or wear. Regular inspection and maintenance can help identify problems early, allowing for timely intervention. Maintenance tips include checking for signs of corrosion or wear, ensuring the screw is properly torqued, and replacing the screw if any damage is detected. These practices help prolong the lifespan of the part and maintain the integrity of the truck’s systems 3.

Cummins Overview

Cummins is a renowned manufacturer with a rich history in the commercial truck industry. The company offers a wide range of products designed to meet the demands of heavy-duty applications. Cummins is recognized for its commitment to quality, innovation, and customer satisfaction, making it a trusted name among truck operators and maintenance professionals. The company’s extensive product range includes engines, powertrain components, and aftermarket parts, all of which are engineered to deliver reliable performance and durability 4.

Studded Flange Cap Screw 3970326 in Cummins Engines

The Studded Flange Cap Screw 3970326, manufactured by Cummins, is a critical component in various engine models. This part is integral to the assembly and maintenance of several Cummins engines, ensuring secure fastening and stability.

B6.7 Series Engines

The B6.7 series engines, including the B6.7 CM2350 B135B and B6.7 CM2670 B153B, utilize the 3970326 screw in their construction. These engines are known for their robust performance and reliability, often found in heavy-duty applications.

D4.0 Series Engines

The D4.0 CM2620 D103B engine also incorporates the 3970326 screw. This engine is designed for durability and efficiency, making it suitable for various industrial uses.

F4.5 Series Engines

The F4.5 CM2620 F139B engine features the 3970326 screw in its design. This engine is engineered for high performance and is often used in demanding environments.

ISB/ISD Series Engines

The ISB/ISD series engines, such as the ISB/ISD4.5 CM2150 B119 and ISB/ISD6.7 CM2150 SN, integrate the 3970326 screw. These engines are known for their versatility and are widely used in both commercial and industrial applications.

ISBE Series Engines

The ISBE series engines, including the ISBE CM2150, ISBE CM800, and ISBE4 CM850, utilize the 3970326 screw. These engines are designed for high efficiency and are often used in various heavy-duty applications.

ISX Series Engines

The ISX series engines, such as the ISX12 CM2350 X102 and ISX12/ISX11.9 CM2250, incorporate the 3970326 screw. These engines are known for their power and reliability, making them suitable for heavy-duty tasks.

QSB Series Engines

The QSB series engines, including the QSB4.5 CM850 (CM2850), QSB7 CM2880 B117, and QSX11.9 CM2250 ECF, use the 3970326 screw. These engines are designed for durability and are often used in demanding applications.

QSF Series Engines

The QSF series engines, such as the QSF2.8 CM2880 F105 and QSF2.8 CM2880 F114, incorporate the 3970326 screw. These engines are engineered for high performance and are often used in industrial settings.

QSG Series Engines

The QSG12/X12 CM2350 G110 engine utilizes the 3970326 screw. This engine is designed for heavy-duty applications and is known for its reliability.

QSK Series Engines

The QSK series engines, including the QSK95 CM2350 K111 and QSK95 CM2350 K113, incorporate the 3970326 screw. These engines are known for their power and are often used in demanding environments.

QSZ Series Engines

The QSZ series engines, such as the QSZ13 CM2150 Z101 and QSZ13 CM2150 Z102, use the 3970326 screw. These engines are designed for durability and are often used in heavy-duty applications.

X12 and X15 Series Engines

The X12 CM2350 X119B, X15 CM2350 X116B, X15 CM2350 X123B, and X15 CM2450 X134B engines incorporate the 3970326 screw. These engines are known for their reliability and are often used in various industrial applications.

Role of Part 3970326 Studded Flange Cap Screw in Engine Systems

The Part 3970326 Studded Flange Cap Screw is instrumental in securing and maintaining the integrity of various engine components. Its primary function is to ensure that parts remain firmly attached, thereby contributing to the overall stability and performance of the engine system.

Breather and Crankcase

In the breather and crankcase systems, the Part 3970326 Studded Flange Cap Screw is used to secure covers and housings. This ensures that the breather system, which allows for the release of pressure and contaminants from the crankcase, operates efficiently without leaks. The screw’s studded flange design provides additional sealing, which is essential for maintaining the crankcase’s vacuum integrity.

Valve and Drain Components

For valve and drain components, the Part 3970326 is employed to fasten covers and housings that protect these elements. In valve systems, it ensures that the valve cover remains securely in place, preventing oil leaks and contaminants from entering the engine. In drain systems, it helps maintain a tight seal around the drain plug, ensuring that oil changes are performed without spillage.

Remote Oil Filter and Fuel Systems

In remote oil filter setups, the Part 3970326 is used to secure the filter housing to the engine block or other mounting points. This is vital for maintaining the oil filtration system’s efficiency and preventing oil leaks. Similarly, in fuel systems, it is utilized to fasten fuel pump housings and filter assemblies, ensuring a secure and leak-free connection.

Flywheel Housing and Harness

The flywheel housing, which encloses the flywheel and starting motor, relies on the Part 3970326 to maintain a secure fit. This is important for the proper operation of the starting motor and the overall balance of the engine. Additionally, the screw is used in securing the electronic control module (ECM) wiring harness to the engine block, ensuring that electrical connections remain intact and protected.

Mounting and Starting Motor

For mounting applications, the Part 3970326 is often used to secure various engine components to the chassis or engine block. This includes mounting brackets for the starting motor, ensuring that it remains firmly in place during engine operation. The screw’s design provides both strength and a secure fit, which is essential for the reliable operation of the starting system.

Pump and Recirculation Systems

In pump and recirculation systems, the Part 3970326 is used to fasten pump housings and recirculation valve covers. This ensures that these components remain securely attached, allowing for efficient fluid movement within the engine system. The screw’s studded flange provides additional sealing, which is crucial for preventing leaks in these high-pressure systems.

Exhaust System

Finally, in the exhaust system, the Part 3970326 is used to secure exhaust manifold covers and housings. This ensures that the exhaust system remains sealed, preventing leaks that could affect engine performance and emissions. The screw’s design helps maintain a tight seal, which is essential for the efficient operation of the exhaust system.

Conclusion

The 3970326 Studded Flange Cap Screw by Cummins is a critical component in the maintenance and operation of commercial trucks. Its robust design, durable construction, and precise engineering make it an essential part for securing various engine components. Proper installation and regular maintenance of this part contribute to the overall reliability and performance of truck systems, ensuring efficient and effective operation in heavy-duty applications.

-

Denton, T., & Pells, H. (2022). Automotive Technician Training Theory. Routledge.

↩ ↩ -

Happian-Smith, J. (2002). An Introduction to Modern Vehicle Design. Butterworth-Heinemann.

↩ ↩ -

Khajepour, A. (2023). Synthesis Lectures on Advances in Automotive Technology. Springer.

↩ ↩ -

Brach, R. M. (2023). SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE Books.

↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.