This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

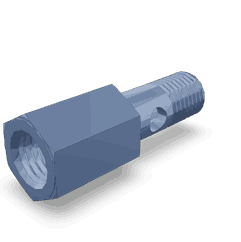

Introduction To Banjo Connector Screws

Banjo connector screws are essential components in the fluid systems of commercial trucks. These screws are critical for the operation of various systems, including fuel, oil, and coolant lines. A banjo connector screw secures the hose to the fitting, ensuring a leak-proof connection. This article explores the specifics of the Cummins part #3964537 banjo connector screw, its role in truck engines, and maintenance tips.

The Role Of The Cummins Part #3964537 Banjo Connector Screw

The Cummins part #3964537 banjo connector screw is designed to provide a secure and reliable connection between the hose and the fitting. This screw is crucial in maintaining the integrity of the fluid system, preventing leaks that could lead to engine damage or failure. The screw’s design ensures that the hose is tightly clamped, which is vital for maintaining system pressure and efficiency 1.

Operational Importance In Truck Engines

In the context of commercial truck engines, the banjo connector screw plays a pivotal role. It ensures that the fluid systems operate smoothly and efficiently. For instance, in the fuel system, a leak could lead to fuel loss and engine performance issues. Similarly, in the oil and coolant systems, a secure connection is essential to prevent overheating and engine damage. The Cummins part #3964537 banjo connector screw is engineered to withstand the demanding conditions of commercial truck operations, ensuring reliable performance under various loads and environments 2.

Troubleshooting And Maintenance

Regular maintenance and timely troubleshooting are crucial for the longevity and efficiency of the banjo connector screw. Here are some tips:

- Inspection: Regularly inspect the banjo connector screw for signs of wear or damage. Look for cracks, corrosion, or looseness in the screw. Early detection of issues can prevent more significant problems down the line.

- Tightening: Ensure the screw is tightened to the manufacturer’s specifications. Over-tightening can damage the fitting, while under-tightening can lead to leaks. Using a torque wrench can help achieve the precise tightening required.

- Replacement: If the screw shows signs of wear, replace it immediately. Using a worn-out screw can compromise the integrity of the fluid system and lead to potential failures.

- Cleaning: Keep the area around the banjo connector screw clean and free from debris. This prevents contamination and ensures a secure connection. Regularly cleaning the area can also help in early detection of any potential issues.

Cummins: A Leader In Truck Engine Technology

Cummins is a renowned name in the automotive and heavy-duty truck industry. Known for its high-quality and reliable parts, Cummins has been a trusted partner for fleet operators and mechanics worldwide. The Cummins part #3964537 banjo connector screw is a testament to Cummins’ commitment to providing durable and efficient components for commercial trucks. Cummins’ reputation for quality and reliability ensures that their parts, including the banjo connector screw, meet the highest standards of performance and durability 3.

Expert Insights

Understanding the intricacies of the banjo connector screw is essential for engineers, mechanics, and fleet operators. Proper maintenance and troubleshooting can prevent costly repairs and ensure the smooth operation of the truck’s fluid systems. By adhering to the manufacturer’s guidelines and regularly inspecting the components, professionals can maintain the integrity of their trucks’ systems. Additionally, staying informed about the latest advancements and best practices in maintenance can further enhance the performance and longevity of commercial trucks.

Cummins Banjo Connector Screw 3964537 in Engine Applications

The Cummins Banjo Connector Screw 3964537 is a critical component in various engine systems, ensuring secure and leak-proof connections for fluid lines. This part is designed to work seamlessly with several Cummins engine models, providing reliability and durability in demanding environments.

ISB CM850 Engines

In the ISB CM850 engines, the Banjo Connector Screw 3964537 is integral to maintaining the integrity of the fuel and hydraulic systems. Its robust construction and precise fitment ensure that connections remain tight and secure, even under high-pressure conditions. This screw is particularly important in applications where fluid leaks can lead to significant performance issues or safety hazards.

Grouped Engine Applications

The Banjo Connector Screw 3964537 is also compatible with a range of other Cummins engines, where it performs similar functions. In these engines, the screw is used to attach banjo bolts to fluid lines, ensuring that connections are both secure and leak-proof. This is crucial for maintaining the efficiency and reliability of the engine’s hydraulic and fuel systems.

The screw’s design allows for easy installation and removal, making it a preferred choice for maintenance and repair operations. Its compatibility with various engine models underscores its versatility and importance in the Cummins engine ecosystem.

Role of Part 3964537 Banjo Connector Screw in Engine Systems

In the realm of engine systems, the Banjo Connector Screw, identified by part number 3964537, serves as a pivotal component in ensuring the efficient operation of various subsystems.

Engine Coolant System

Within the engine coolant system, the Banjo Connector Screw is instrumental in maintaining the integrity of coolant flow. It is typically employed in the connection between the engine block and the radiator hoses, where it secures the banjo bolt. This setup allows for a reliable seal, preventing coolant leaks that could lead to engine overheating. The screw’s design facilitates easy disassembly and reassembly, which is essential during maintenance or repair procedures.

Vent System

In the vent system, the Banjo Connector Screw plays a significant role in managing pressure and ensuring proper ventilation within the engine compartment. It is often used in the connections of breather hoses, which allow for the release of excess pressure from the crankcase. This helps in maintaining optimal engine performance and longevity by preventing the buildup of harmful gases and moisture. The secure fit provided by the Banjo Connector Screw ensures that the vent system operates efficiently, contributing to the overall stability and reliability of the engine.

Conclusion

This article aims to provide a comprehensive understanding of the Cummins part #3964537 banjo connector screw, its role in truck engines, and the importance of regular maintenance. By following the tips and insights provided, professionals can ensure the longevity and efficiency of their commercial trucks.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.