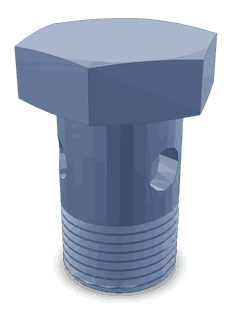

3958987

Banjo Connector Screw

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3958987 Banjo Connector Screw, manufactured by Cummins, is a specialized component used in commercial trucks. A banjo connector screw is a type of fitting used in automotive and industrial applications to connect hoses to various fluid systems. Its design allows for secure and leak-free connections, which are vital in systems such as fuel injection, hydraulics, and brakes.

Basic Concepts and Functionality

Banjo connector screws operate on the principle of creating a sealed connection between a hose and a fitting within fluid systems. They typically consist of a bolt with an integrated fitting that allows a hose to be clamped securely. The sealing mechanism involves a gasket or O-ring that ensures no fluid escapes when the system is pressurized. This design is particularly useful in applications where vibrations and movement are common, as it provides a robust connection that can withstand dynamic conditions 1.

Purpose and Role in Truck Operation

In the context of a commercial truck, the 3958987 plays a role in maintaining secure and leak-free connections in critical systems. It is used in fuel injection systems to ensure that fuel is delivered efficiently and without leaks. In hydraulic systems, it helps maintain the integrity of the fluid lines, which is crucial for the operation of various truck components. Additionally, in brake systems, it ensures that brake fluid is contained within the lines, contributing to the overall safety and performance of the vehicle 2.

Key Features

The 3958987 is designed with several key features that enhance its performance and durability. It is typically made from high-strength materials to withstand the pressures and conditions found in heavy-duty applications. The thread type is chosen to provide a secure fit, and the design may include features such as a hex head for easy tightening with standard tools. These elements contribute to the connector’s effectiveness in demanding environments.

Benefits

Using the 3958987 offers several benefits. Its design allows for improved sealing capabilities, which is crucial in preventing leaks in fluid systems. The material composition provides resistance to corrosion and high pressures, ensuring longevity in harsh operating conditions. Additionally, the ease of installation and maintenance makes it a practical choice for technicians working on commercial trucks.

Installation Process

Proper installation of the 3958987 involves several steps to ensure a secure and reliable connection. It is important to use the correct torque settings to avoid over-tightening, which can damage the fitting, or under-tightening, which can lead to leaks. Appropriate tools should be used to install the connector, and it is advisable to follow the manufacturer’s guidelines for the best results.

Troubleshooting and Maintenance

Common issues with banjo connector screws may include leaks, corrosion, or wear. Regular inspection can help identify these problems early. Maintenance tips include checking for signs of wear or damage, ensuring that connections are tight, and replacing the connector if any issues are found. This proactive approach can help prevent system failures and ensure the continued safe operation of the truck.

Safety Considerations

When working with banjo connector screws, it is important to observe safety practices to prevent accidents. Potential hazards include fluid leaks, which can be hazardous if the fluid is flammable or toxic. It is crucial to mitigate these risks by working in a well-ventilated area and having appropriate safety equipment on hand. Following manufacturer guidelines and industry standards is also important to ensure safe and effective use of the connector.

Cummins: Manufacturer Overview

Cummins Inc. is a well-established manufacturer with a strong reputation in the automotive industry, particularly for diesel engines and related components. The company has a history of innovation and commitment to quality, which is reflected in its product line. Cummins’ expertise in engine technology and component manufacturing makes it a trusted name in the industry, providing reliable and high-performance parts for commercial vehicles 3.

Compatibility of 3958987 with Cummins Engines

The 3958987, manufactured by Cummins, is designed to fit seamlessly with a variety of Cummins engines. This part is integral in ensuring a secure and leak-proof connection in the fuel and hydraulic systems of these engines.

ISB CM2150 and ISB CM850 Engines

The ISB CM2150 and ISB CM850 engines are part of Cummins’ Intelligent Systems for Better Performance (ISB) series. These engines are known for their robust design and efficiency. The 3958987 is compatible with these engines, providing a reliable connection for fuel and hydraulic lines.

QSB5.9 CM850 and QSB6.7 CM850 (CM2850) Engines

The QSB5.9 CM850 and QSB6.7 CM850 (CM2850) engines are part of Cummins’ Quanti-Shift Series. These engines are designed for heavy-duty applications and are widely used in various industries. The 3958987 is engineered to fit these engines, ensuring that the connections remain tight and secure under demanding conditions.

QSB6.7 M CM2250 Engine

The QSB6.7 M CM2250 engine is another variant in the Quanti-Shift Series, designed for medium-duty applications. This engine benefits from the precise fit and durability of the 3958987, which is essential for maintaining the integrity of the fuel and hydraulic systems.

By ensuring compatibility with these engines, the 3958987 helps maintain the performance and reliability of Cummins engines across various applications.

Role of 3958987 in Fuel Systems

The 3958987 is integral to the efficient operation of fuel systems in various engine setups. This component facilitates the secure connection between fuel lines and other fuel system components, ensuring a reliable and leak-free interface.

Fuel Filter Integration

In fuel filter assemblies, the 3958987 plays a significant role by connecting the fuel lines to the filter housing. This ensures that fuel flows smoothly from the tank to the engine, while contaminants are effectively trapped within the filter. The secure fitting provided by the 3958987 prevents any fuel leakage, maintaining system integrity and performance.

Fuel Plumbing Applications

Within the broader context of fuel plumbing, the 3958987 is employed to join different sections of fuel lines. This is particularly important in high-pressure fuel systems where any leak could result in a dangerous situation. The screw’s design allows for a tight seal, which is essential for maintaining the pressure required for optimal engine performance.

Connection to Fuel Injectors

The 3958987 is also utilized in connecting fuel lines to fuel injectors. This application is vital as it ensures that fuel is delivered precisely and consistently to each injector. The secure connection minimizes the risk of fuel leaks and maintains the correct fuel pressure, which is necessary for the injectors to atomize fuel efficiently for combustion.

General Fuel System Plumbing

Across various fuel system plumbing applications, the 3958987 serves as a versatile component. Whether connecting fuel rails, fuel pumps, or other ancillary components, its role in creating a dependable seal cannot be overstated. This reliability is fundamental to the overall efficiency and safety of the fuel delivery system.

Conclusion

In summary, the 3958987 Banjo Connector Screw is a key element in the fuel system, ensuring that connections are secure, leaks are prevented, and fuel is delivered efficiently throughout the engine system. Its compatibility with various Cummins engines and its role in maintaining the integrity of fuel and hydraulic systems make it an essential component for the reliable operation of commercial trucks.

-

Automotive Braking Systems CDX Master Automotive Technician Series, Nicholas Goodnight and Kirk VanGelder, Jones Bartlett Learning, 2019

↩ -

Advanced Direct Injection Combustion Engine Technologies and Development Volume 2 Diesel Engines, Hua Zhao, CRC Press, 2010

↩ -

Aerodynamics of Road Vehicles: Fifth Edition, Thomas Schuetz, SAE International, 2016

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.